A method and device for chemically recovering water based on a solar gas turbine system

A gas turbine and solar energy technology, applied in the direction of gas turbine devices, chemical instruments and methods, jet propulsion devices, etc., can solve problems such as increased system water consumption, poor condensation effect, and manufacturing difficulties, so as to improve power generation efficiency and reduce compressors Effect of power consumption and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The method and device for chemically recovering water based on the solar gas turbine system will be clearly and completely described below with reference to the accompanying drawings.

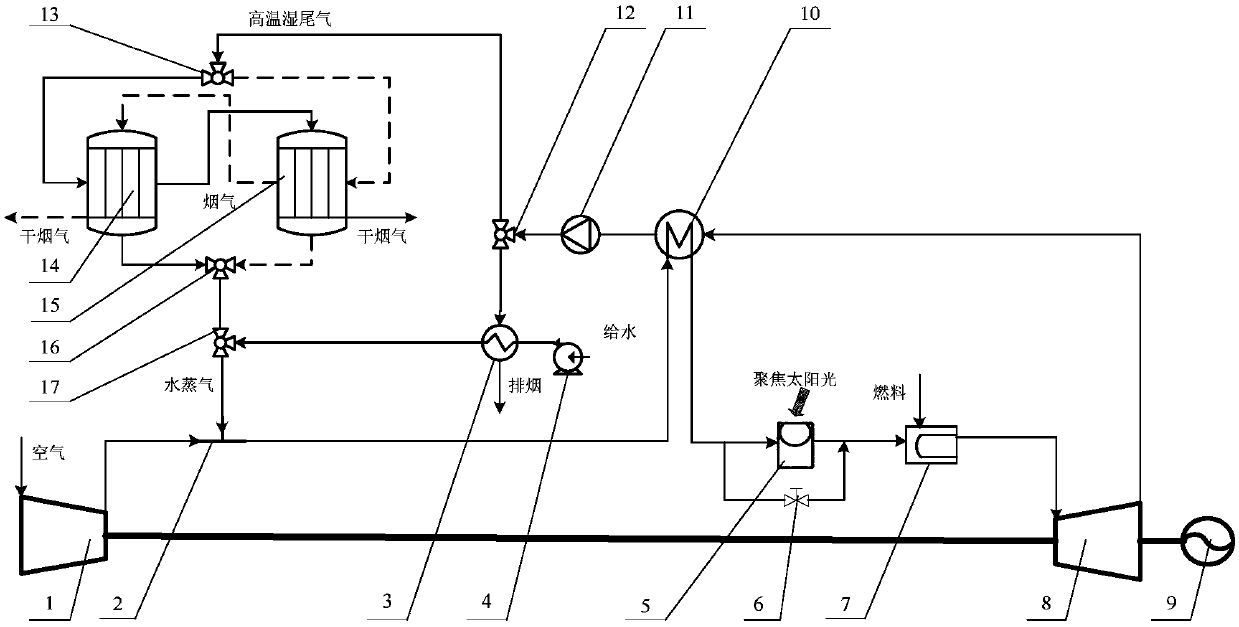

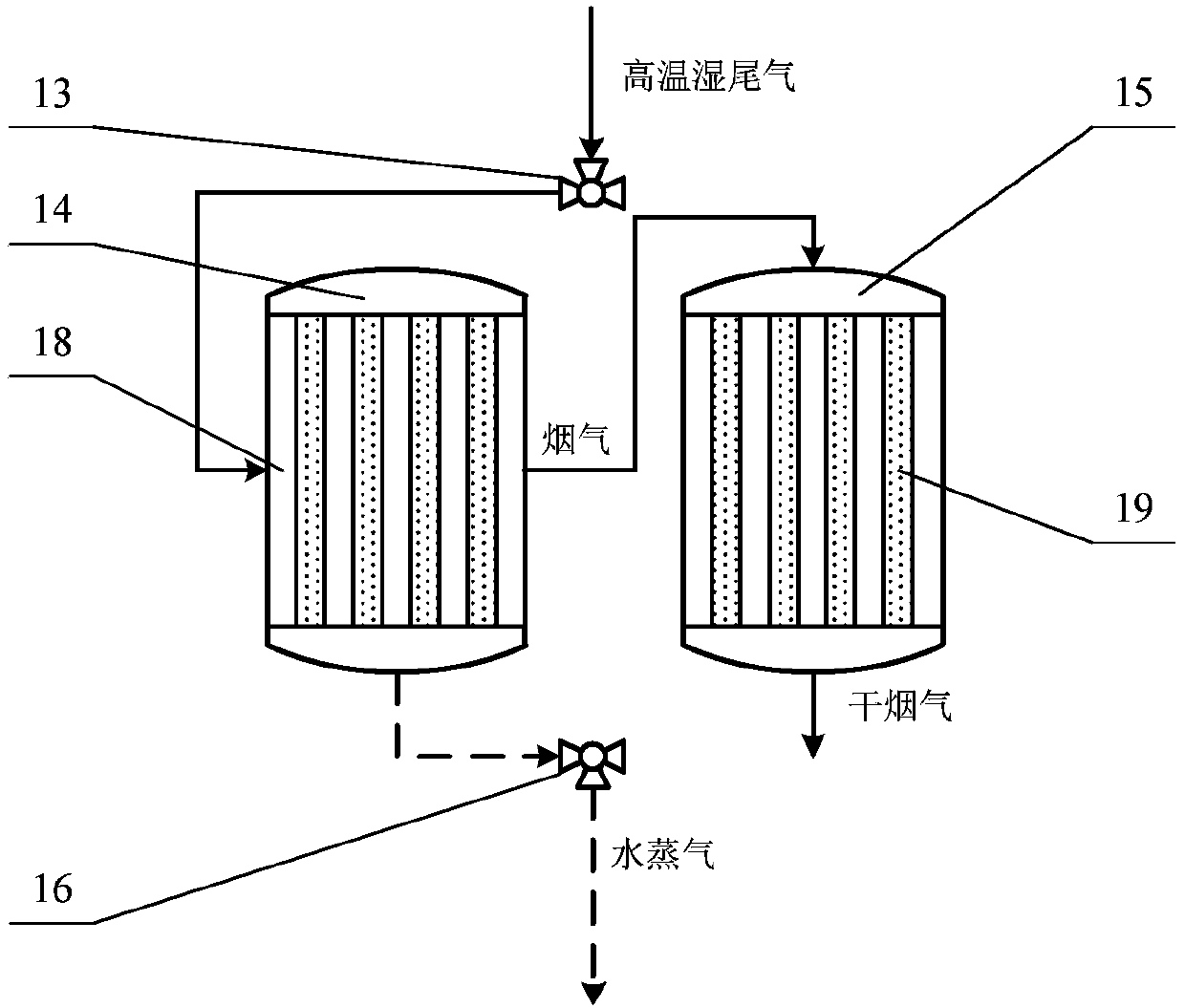

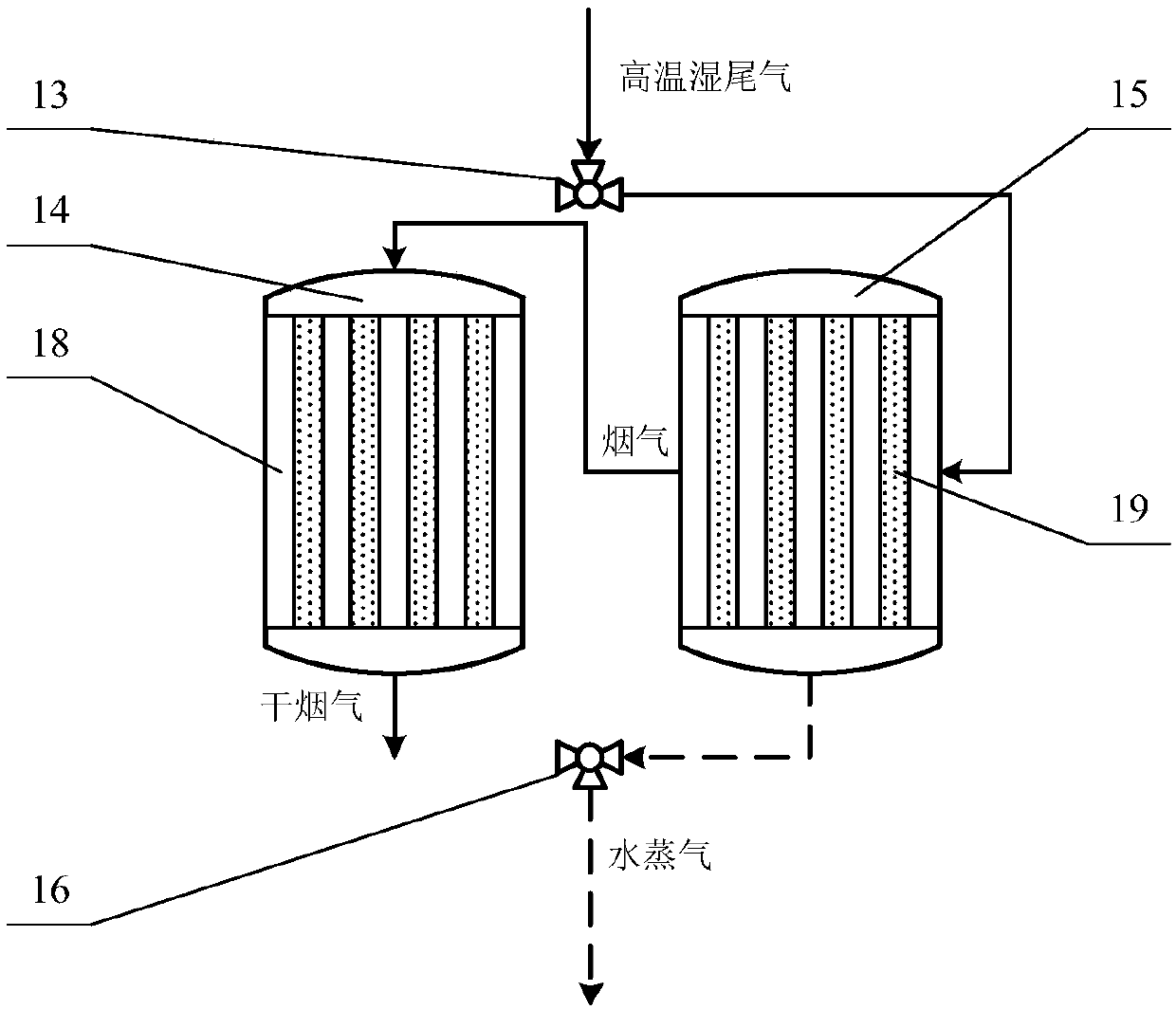

[0028] Such as figure 1 As shown, a chemical formula water recovery method and device based on a solar gas turbine system, including a compressor 1, a mixer 2, a steam generator 3, a feed water pump 4, a solar heat collector 5, a valve A 6, a combustion chamber 7, a gas Turbine 8, generator 9, regenerator 10, booster pump 11, valve B 12, valve C 13, partition reactor A 14, partition reactor B 15, valve D 16, valve E 17. The outlet of compressor 1 is connected to the inlet of mixer 2, the outlet of mixer 2 is connected to the cold fluid side inlet of regenerator 10, the cold fluid side outlet of regenerator 10 is connected to the inlet of solar collector 5, and the outlet of solar collector 5 is connected to combustion The inlet of chamber 7, the outlet of combustion chamber 7 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com