Super-energy-saving air jet loom and utilization method thereof

An air-jet loom, ultra-energy-saving technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of unstable air pressure, increased temperature of compressed gas, fabric defects, etc., to save energy and reduce consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below in conjunction with accompanying drawing:

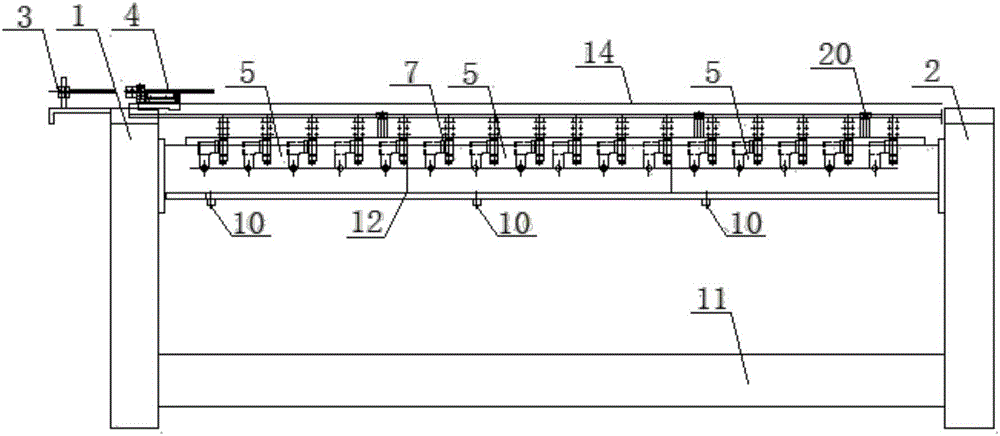

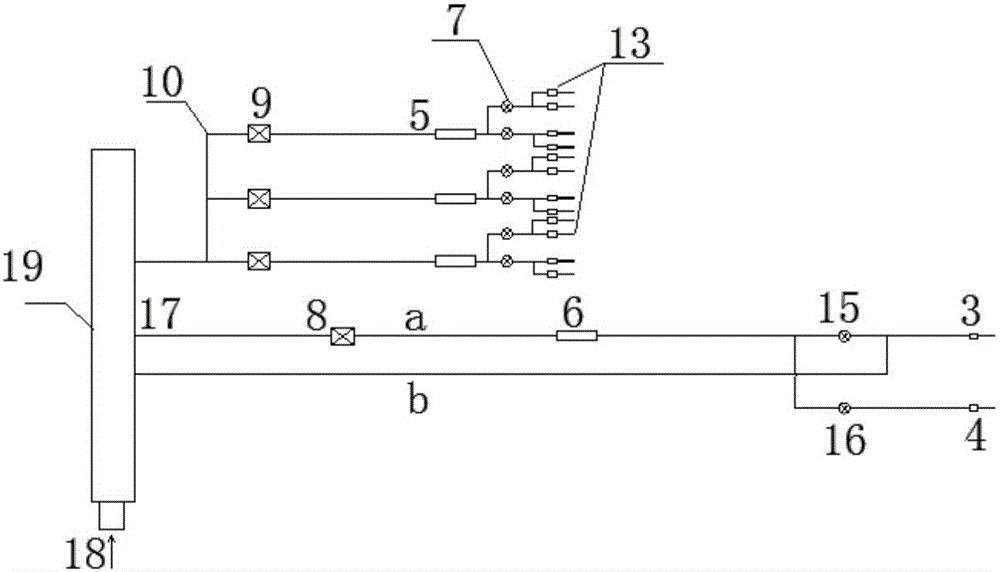

[0035] Such as Figure 1-2 As shown, a super-energy-saving air-jet loom includes a left wall panel 1, a right wall panel 2, a main spray system, an auxiliary spray system and a multi-purpose seat 19;

[0036] The main spray system includes a swing main spray 4, a swing main spray solenoid valve 15, a fixed main spray 3, a fixed main spray solenoid valve 16, a sley 14, a main spray package 6, a first pressure regulating valve 8 and a main spray intake port 17, one end of the swing main spray solenoid valve 15 is connected with the swing main spray 4, the other end is connected with the main spray package 6 and the first pressure regulating valve 8 in turn, one end of the fixed main spray solenoid valve 16 is connected with the fixed main spray 3. The other end is sequentially connected to the main jet package 6 and the first pressure regulating valve 8, and the first pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com