A kind of anti-carburization coating specially used for finishing parts and preparation method thereof

A technology for anti-carburizing coatings and components, applied in coatings, metal material coating processes, solid-state diffusion coatings, etc. Uniformity and stability, good wetting and fluidity, good anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

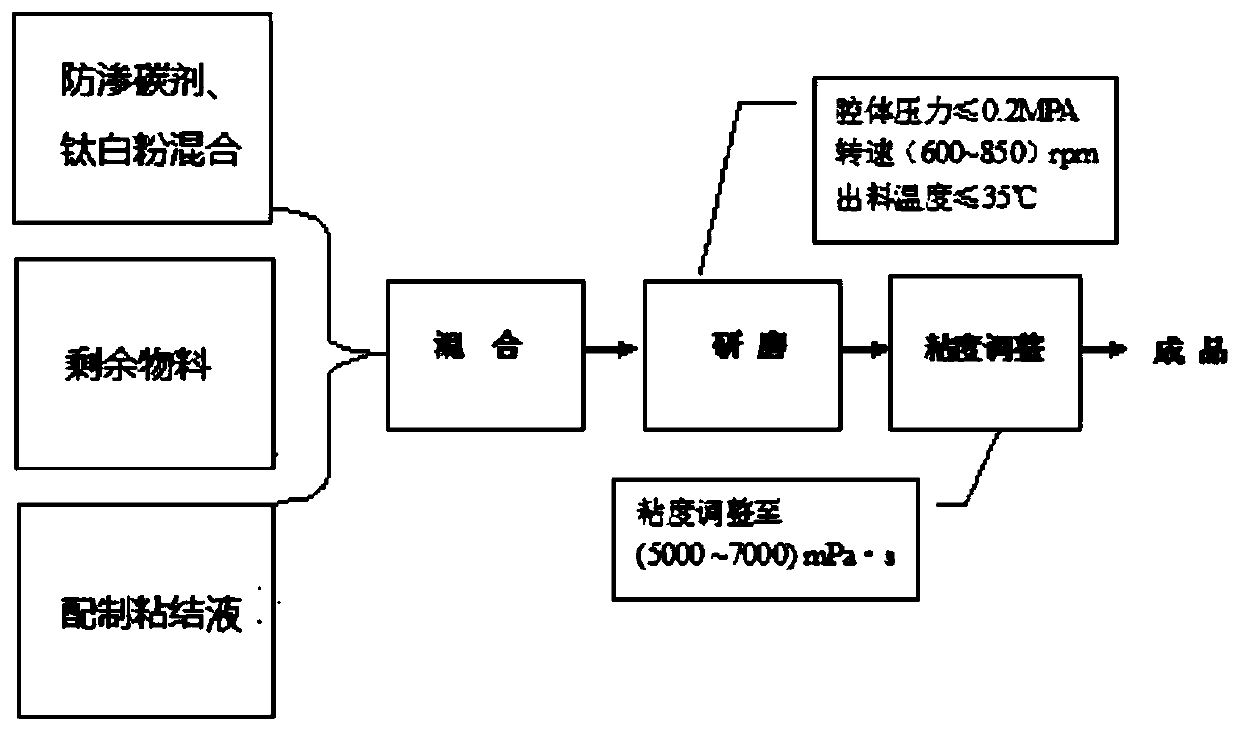

Method used

Image

Examples

Embodiment 1

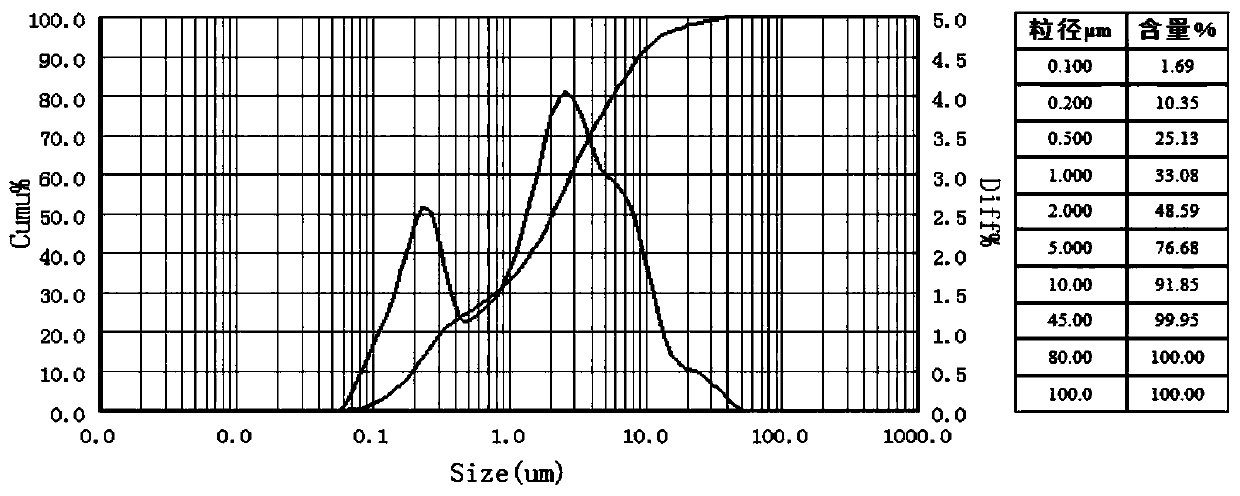

[0030] The anti-carburizing coating specially used for finishing parts of the present invention is formed by mixing and grinding the following components by mass percentage: 12% boric anhydride powder, 4% cuprous oxide powder, 10% titanium dioxide, 30% phosphoric acid Aluminum dihydrogen, 5% ethanol, 5% tetrasodium EDTA, 3% sodium carboxymethylcellulose, 1% triethanolamine, 0.5% polyether modified silicon defoamer, 0.5% nonylphenol polyoxyethylene ether, 1 % ferrous sulfate and 28% deionized water; the particle size of the anti-carburization coating D90≤10μm.

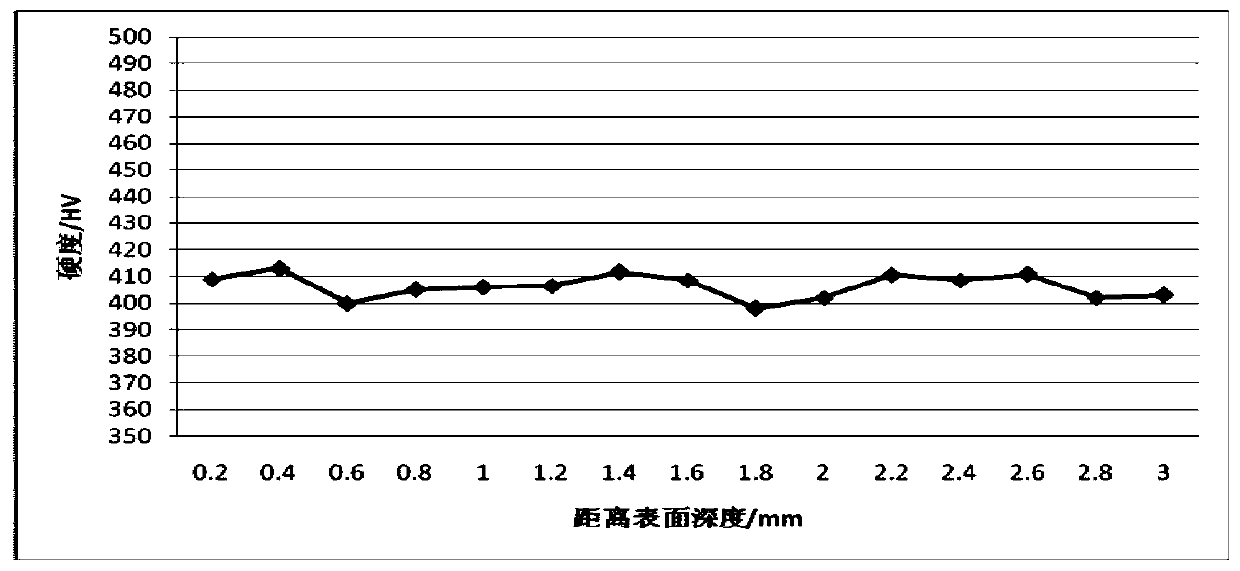

[0031] Use the anti-carburizing coating of Example 1 to carry out anti-carburizing treatment on gears made of 20CrMnTi. The carburized layer depth is 2.5 mm to 3.0 mm. After carburizing, it is directly quenched. After the quenched workpiece is soaked in 60 ° C water for 20 minutes, The anti-carburization coating on the surface is completely peeled off. The hardness of the anti-carburization part of the workpiece is red...

Embodiment 2

[0034] The anti-carburizing coating specially used for finishing parts of the present invention is formed by mixing and grinding the following components by mass percentage: 24% boric anhydride powder, 3% cuprous oxide powder, 15% titanium dioxide, 25% phosphoric acid Aluminum dihydrogen, 3% ethanol, 3% tetrasodium EDTA, 3% sodium carboxymethylcellulose, 1% triethanolamine, 0.5% polyether modified silicon defoamer, 0.5% nonylphenol polyoxyethylene ether, 1 % ferrous sulfate and 21% deionized water, the particle size of anti-carburization coating D90≤10μm.

Embodiment 3

[0036] The anti-carburizing coating specially used for finishing parts of the present invention is formed by mixing and grinding the following components by mass percentage: 16% boric anhydride powder, 4% cuprous oxide powder, 15% titanium dioxide, 25% phosphoric acid Aluminum dihydrogen, 3% ethanol, 3% tetrasodium EDTA, 5% sodium carboxymethylcellulose, 1% triethanolamine, 1% polyether modified silicon defoamer, 0.5% nonylphenol polyoxyethylene ether, 0.5 % ferrous sulfate and 26% deionized water, the particle size of the anti-carburization coating D90≤10μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com