Fermenting tank temperature control bin

A fermentation tank and temperature control technology, applied in the field of fermentation temperature control warehouses, can solve problems such as troublesome layout, increased production costs, complex structure, etc., and achieve the effects of convenient temperature control, simplified structure, and guaranteed fermentation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

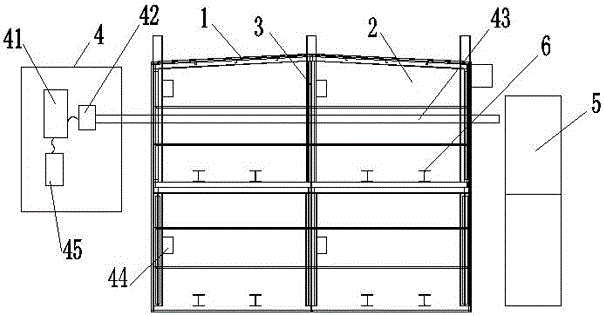

[0016] The present invention includes at least two layers of frames 1 for placing fermentation tanks, each layer of frame 1 is provided with at least two bins 2 for placing fermentation tanks; the lower part of each layer of frame 1 is provided with a walkway for moving the frame 1 Track 6.

[0017] The bins 2 on the same floor are an integral structure, and the adjacent bins 2 are separated by sealed rolling doors 3 .

[0018] A temperature control system 4 is provided, and the temperature control system 4 includes an air conditioner 41 and a fan 42 connected to the air conditioner 41 , and an air duct 43 is provided to penetrate into and out of each frame 1 .

[0019] A shifting device 5 is arranged beside the frame 1 , and the shifting device 5 is used to put the fermentation tank into or remove it from the bin body 2 .

[0020] A plurality of temperature sensors 44 and a controller 45 are arranged inside the warehouse body 2 , and the temperature sensors 44 and the air co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com