Circulating hydraulic oil source system

A hydraulic oil source and circulation technology, which is applied in the direction of fluid pressure actuation system testing, fluid pressure actuation system components, fluid pressure actuation devices, etc., can solve the waste of temperature control costs, slow heating and cooling speed, difficult Satisfies the problems of frequent changes in hydraulic oil temperature, achieves cost savings in temperature control, meets the needs of frequent temperature changes, and improves the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

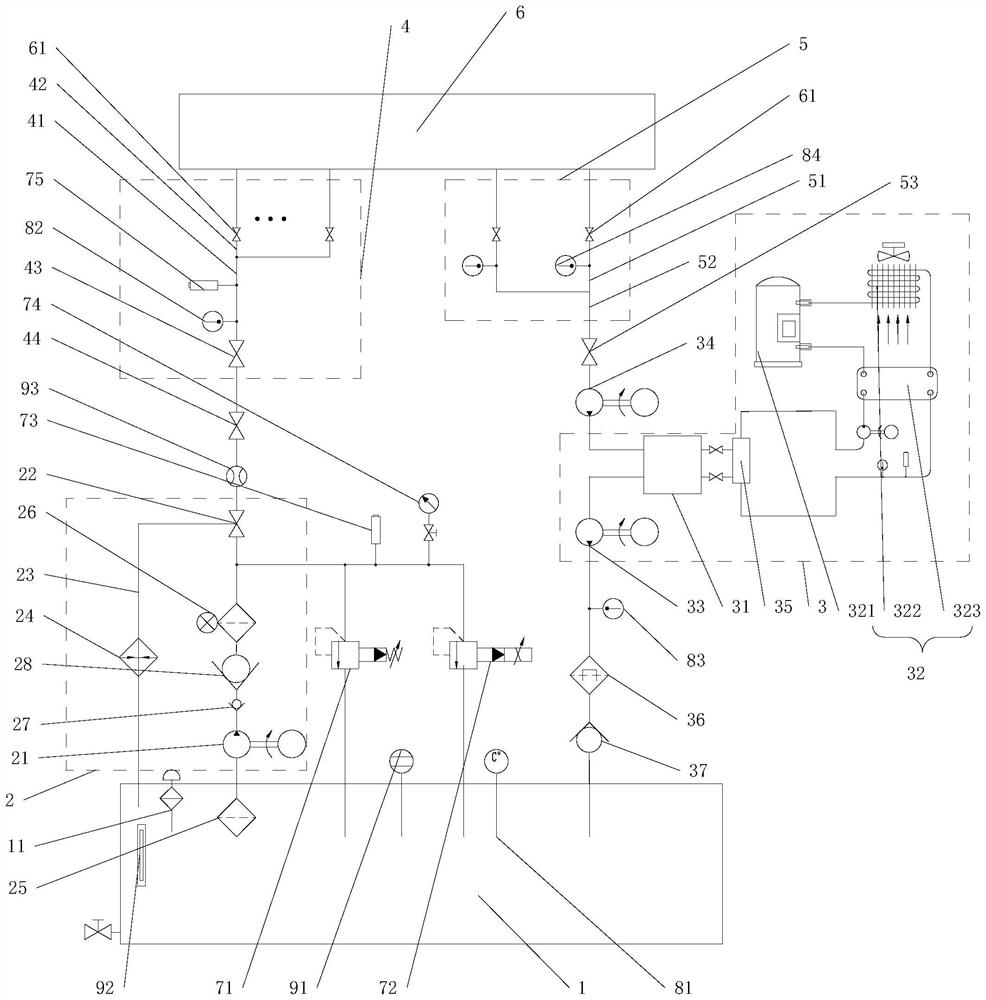

[0024] The cyclic hydraulic oil source system provided by this embodiment has the following technical solutions:

[0025] like figure 1 As shown, the circulating hydraulic oil source system includes a main oil tank 1, a circulating heating module 2 and a cooling module 3. Both the circulating heating module 2 and the cooling module 3 are connected to the main oil tank 1, and the circulating heating module 2 is connected to the oil supply valve module 4 through the oil supply valve module 4. The product to be tested 6 is connected, and the product to be tested 6 is connected to the cooling module 3 through the oil return valve module 5 . The main oil tank 1 is provided with a liquid level sensor 91 , an oil tank temperature sensor 81 and an air filter 11 , and a stainless steel welding sight glass 92 is installed on the side wall of the main oil tank 1 .

[0026] The circulating heating module 2 includes an oil supply pump 21, a check valve 27, a filter check valve 28, an oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com