Adjustable-temperature solid phase synthesis apparatus for polypeptide

A technology for polypeptide solid-phase synthesis and stirring device, which is applied in the fields of peptides, peptide preparation methods, organic chemistry, etc. The effect of low temperature control cost, easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

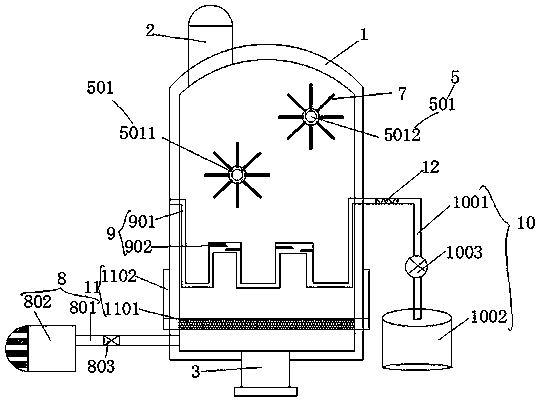

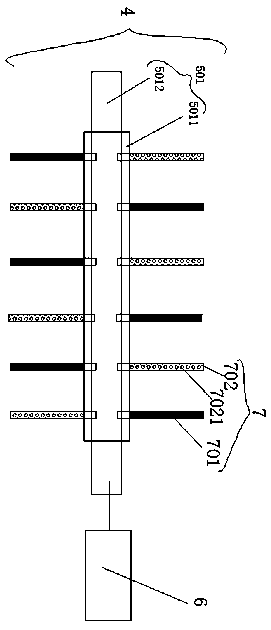

[0024] Embodiment 1: see figure 1 ,and figure 2Now, a temperature-adjustable polypeptide solid-phase synthesis device provided by the present invention is described, including a kettle body 1, a feed inlet 2 is provided at the upper end of the kettle body 1, and a discharge port is provided at the lower end of the kettle body 1 3. The kettle body 1 is provided with a stirring unit 4, the stirring unit 4 includes a plurality of stirring devices 5, the stirring device 5 includes a rotating shaft 501, and the rotating shaft 501 includes a rotating shaft 5011 and a set The drive shaft 5012 in the rotating shaft 5011, the two ends of the driving shaft 5012 are connected to the drive unit 6 outside the still body 1, the center line of the rotating shaft 5011 is perpendicular to the center line of the still body 1, each of the rotating shafts The centerlines of 5011 are parallel to each other, and a number of stirring blades 7 are evenly arranged on the outer periphery of the rotat...

Embodiment 2

[0025] Example 2: see figure 1 As an improvement of the present invention, the vacuum unit 8 includes a vacuum tube 801 and a vacuum pump 802, and the vacuum tube 801 is provided with a control switch 803.

Embodiment 3

[0026] Embodiment 3: see figure 2 , as an improvement of the present invention, the stirring blade 7 is fixed on the rotating shaft 5011 by welding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com