Microcrystalline cellulose-nanometer silicon dioxide hybrid material and preparing method and application thereof

A technology of nano-silica and microcrystalline cellulose, which is applied in rolling resistance optimization, transportation and packaging, special tires, etc., can solve the problems of large MCC particle size, difficulty in dispersing the rubber matrix, and low interaction strength, and achieve improved Reinforcing effect, effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

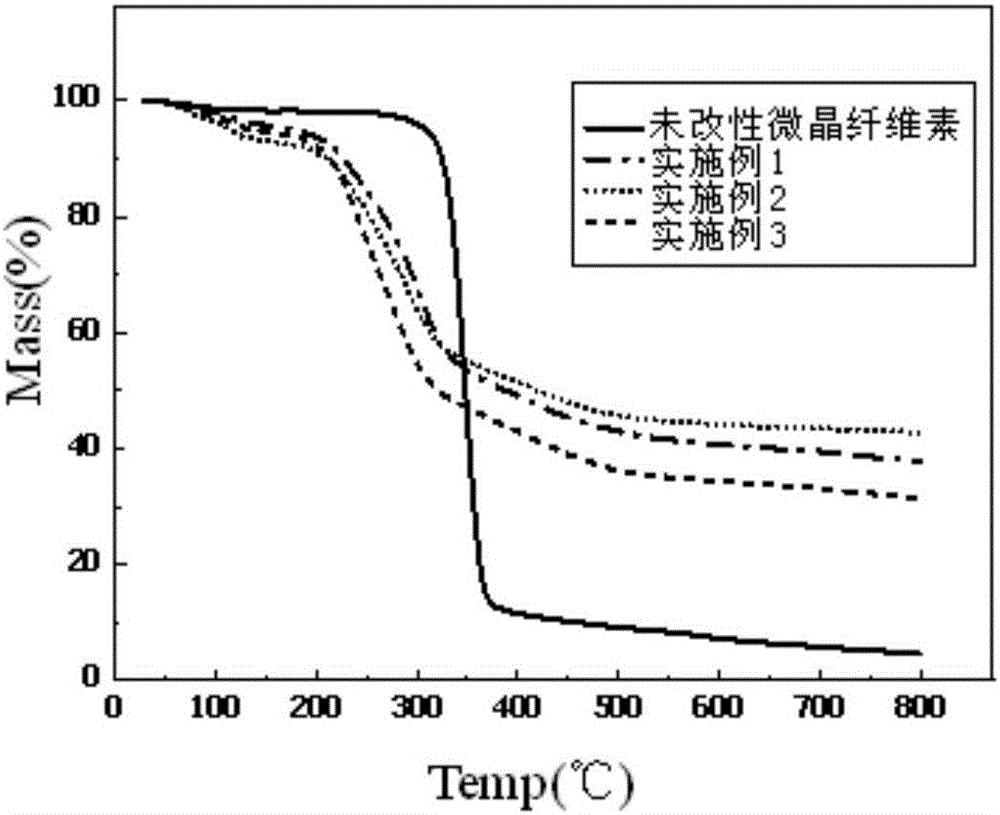

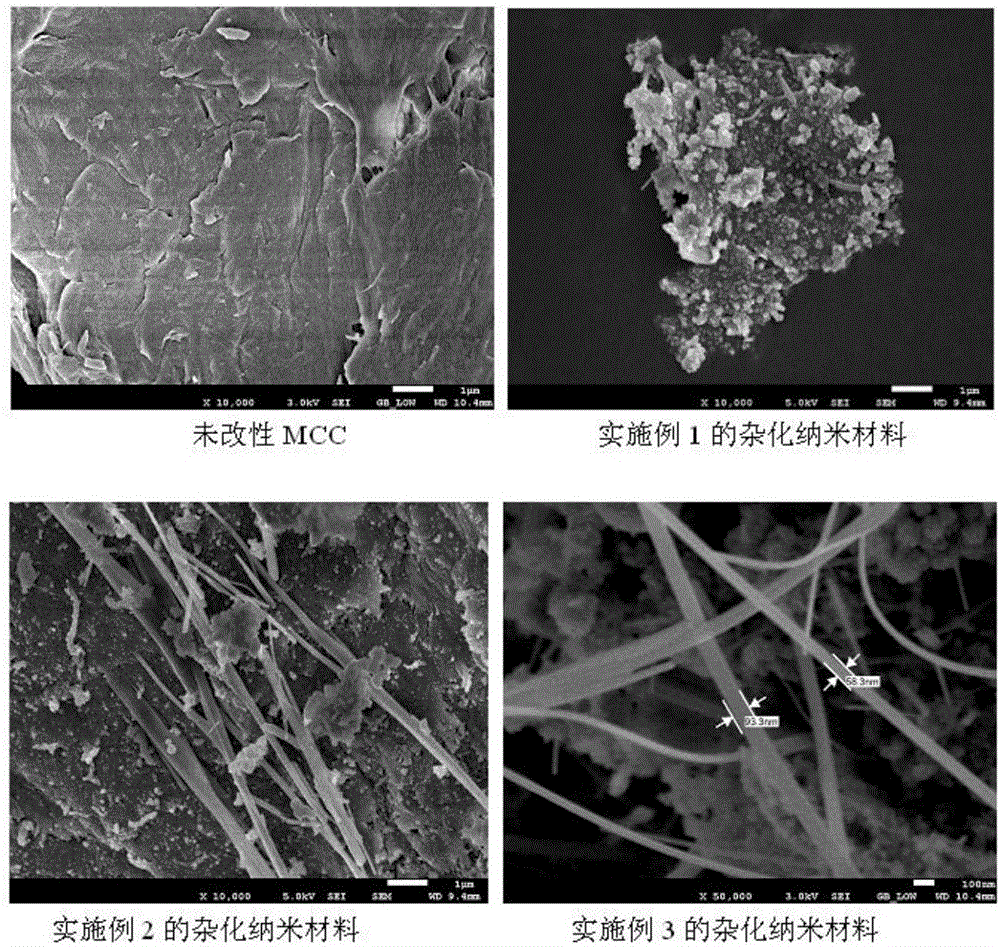

[0031] Example 1 Preparation of microcrystalline cellulose-nano-silica hybrid material

[0032] (1) Disperse 10g of microcrystalline cellulose in 100ml of ethanol, add 80g of sodium hydroxide aqueous solution with a mass concentration of 4%, stir at high speed for 2h and filter with suction;

[0033] (2) At room temperature, vacuum dry the microcrystalline cellulose obtained in step (1) for 2 hours to control the thickness of the microcrystalline cellulose surface adsorbed water film in the range of 10nm-1μm;

[0034] (3) Disperse 5 g of swollen microcrystalline cellulose into 50 ml of ethanol and stir at high speed for 30 minutes;

[0035] (4) Dissolve 5g of ethyl orthosilicate and 1g of bis-(γ-triethoxysilylpropyl) tetrasulfide (Si69) in 100ml of isopropanol;

[0036] (5) The microcrystalline cellulose suspension obtained in step (3) was added dropwise to the ethyl orthosilicate and Si69 solution in step (4), reacted in a water bath at 80°C for 0.5 h, and aged at room temperature for ...

Embodiment 2

[0037] Example 2 Preparation of microcrystalline cellulose nano-silica hybrid material

[0038] (1) Disperse 50 g of microcrystalline cellulose in 150 ml of ethanol solution, add 150 g of sodium hydroxide aqueous solution with a mass concentration of 16%, stir at high speed for 6 hours and filter with suction;

[0039] (2) At room temperature, vacuum dry the microcrystalline cellulose obtained in step (1) for 14 hours to control the thickness of the water adsorption film on the microcrystalline cellulose surface to be 10nm-1μm;

[0040] (3) Disperse 20 g of the swollen microcrystalline cellulose into 200 ml of isopropanol solution and stir at high speed for 30 minutes;

[0041] (4) Dissolve 20g of ethyl orthosilicate and 5g of bis-(γ-triethoxysilylpropyl) tetrasulfide (Si69) in 100ml of ethanol;

[0042] (5) The microcrystalline cellulose suspension obtained in step (3) was added dropwise to the ethyl orthosilicate and Si69 solution in step (4), reacted in a water bath at 80°C for 3 hou...

Embodiment 3

[0043] Example 3 Preparation of microcrystalline cellulose-nano-silica hybrid material

[0044] (1) Disperse 30 g of microcrystalline cellulose in 100 ml of ethanol, add 115 g of sodium hydroxide aqueous solution with a mass concentration of 10%, stir at high speed for 4 hours and filter with suction;

[0045] (2) Vacuum drying the microcrystalline cellulose obtained in step (1) for 20 hours at room temperature to control the thickness of the water adsorption film on the surface of the microcrystalline cellulose to be 10nm-1μm;

[0046] (3) Disperse 12.5g of swollen microcrystalline cellulose into 125ml ethanol and stir at high speed for 45min;

[0047] (4) Dissolve 12.5g of ethyl orthosilicate and 3g of bis-(γ-triethoxysilylpropyl) tetrasulfide (Si69) in 100ml of ethanol;

[0048] (5) The microcrystalline cellulose suspension obtained in step (3) was added dropwise to the ethyl orthosilicate and Si69 solution in step (4), reacted in a water bath at 80°C for 2 hours, and aged at room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com