Waste polyester-cotton textile degrading and recycling process and system

A recycling system and textile technology, applied in the field of polyester and cotton recycling, can solve the problems of continuous reaction of separation methods, inconvenient recycling, poor product purity, etc., and achieve the effects of alleviating resource shortage, reducing pollution and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

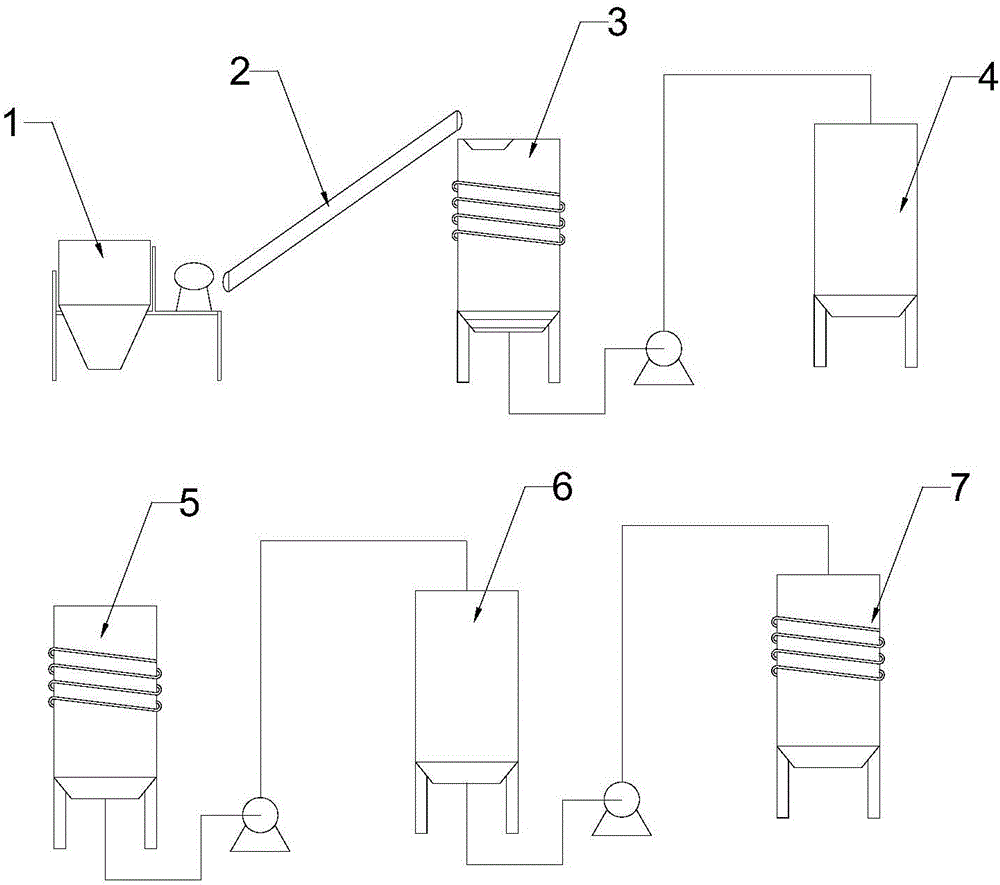

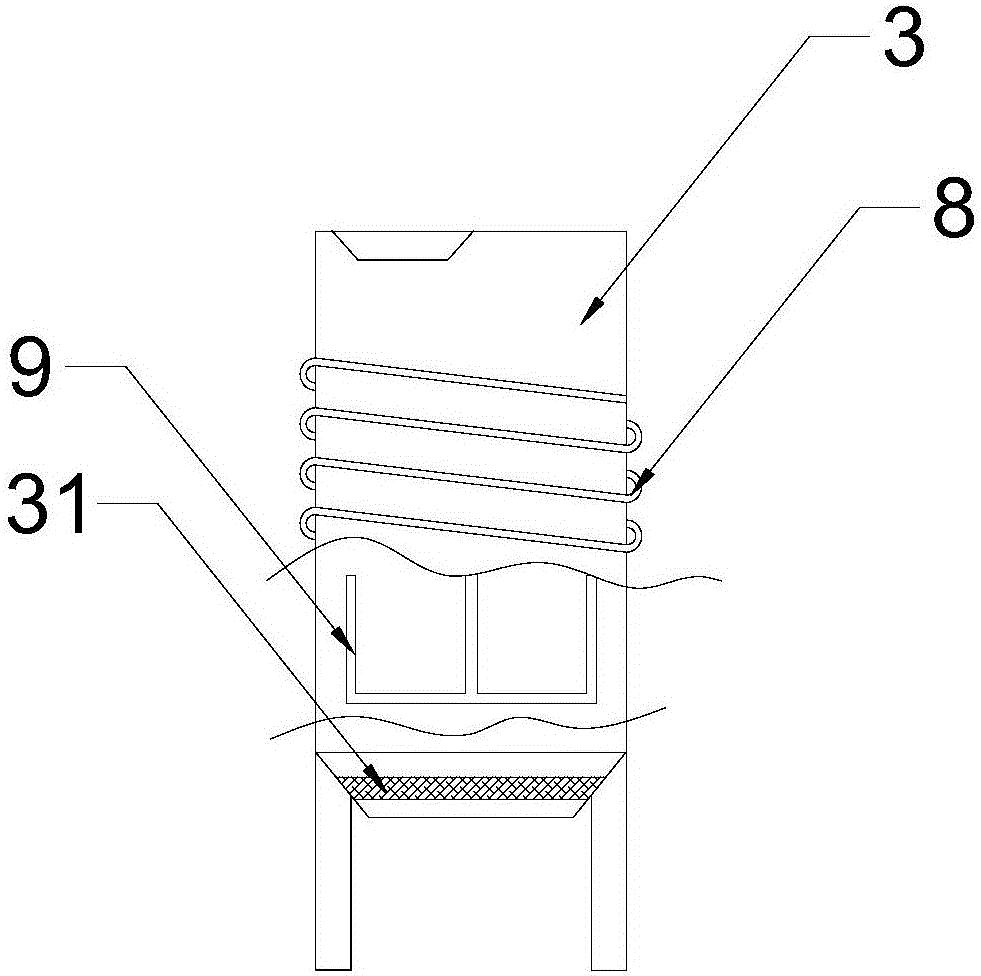

[0037] A process for the degradation and recycling of waste polyester-cotton textiles includes the following steps:

[0038] A. Crush waste polyester / cotton textiles into 2cm cloth strips as raw materials;

[0039] B. Add 80% concentrated phosphoric acid to the raw materials, the mass ratio of the concentrated phosphoric acid to the raw materials is 4:1, and react at 80℃ for 0.5h under stirring. After the reaction is completed, filter to obtain filtrate I and filtrate Ⅰ;

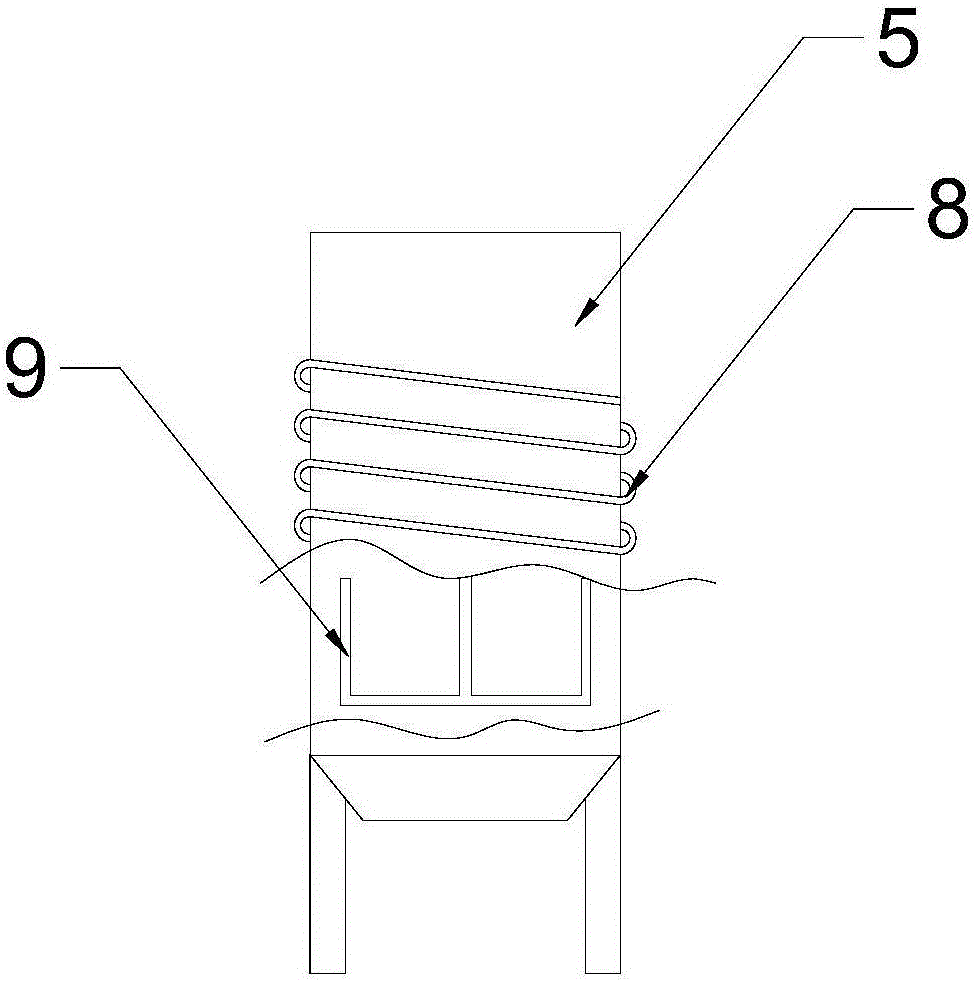

[0040] C. Take the filtrate I and add water and stir for hydrolysis. The volume ratio of the added water to the filtrate I is 3:1; use polyester fiber as a filter to filter the filtrate to obtain filtrate II, which is Cotton fiber;

[0041] D. Take the filtrate I, add 25% sodium hydroxide solution, the mass ratio of sodium hydroxide solution to filtrate I is 3:1, react at 100℃ for 4h, filter after reaction, take the filtrate to filter Liquid II;

[0042] E. Take the filtrate II and add water and stir for dilution. ...

Embodiment 2

[0047] A process for the degradation and recycling of waste polyester-cotton textiles includes the following steps:

[0048] A. Crush waste polyester-cotton textiles into 8cm cloth strips as raw materials;

[0049] B. Add 75% concentrated phosphoric acid to the raw materials, the mass ratio of concentrated phosphoric acid to the raw materials is 6:1, and react at 70°C for 1.5 hours under stirring. After the reaction is completed, filter to obtain filtrate I and filtrate Ⅰ;

[0050] C. Take the filtrate I and add water and stir for hydrolysis. The volume ratio of the added water to the filtrate I is 3:1; use polyester fiber as a filter to filter the filtrate to obtain filtrate II, which is Cotton fiber;

[0051] D. Take the filtrate I, add 20% sodium hydroxide solution, the mass ratio of sodium hydroxide solution to filtrate I is 5:1, react at 90℃ for 6h, filter after the reaction, take the filtrate to filter Liquid II;

[0052] E. Take the filtrate II and add water and stir for dilut...

Embodiment 3

[0057] A process for the degradation and recycling of waste polyester-cotton textiles includes the following steps:

[0058] A. Crush waste polyester-cotton textiles into 5cm strips as raw materials;

[0059] B. Add 78% of concentrated phosphoric acid to the raw material, the mass ratio of concentrated phosphoric acid to the raw material is 5:1, react for 1 hour at 75°C under stirring, and filter after the reaction is completed to obtain filtrate I and filtrate I ;

[0060] C. Take the filtrate I and add water and stir for hydrolysis. The volume ratio of the added water and filtrate I is 3:1; use the polypropylene fiber as the filter to filter out the filtrate to obtain filtrate II, which is Cotton fiber;

[0061] D. Take the filtrate I, add 22% sodium hydroxide solution, the mass ratio of sodium hydroxide solution to filtrate I is 4:1, react at 95℃ for 5h, filter after the reaction, take the filtrate to filter Liquid II;

[0062] E. Take the filtrate II and add water and stir for di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com