C/C radiating fin and stainless steel connection method

A technology of heat dissipation fins and connection methods, applied in the field of connection between composite materials and metals, can solve the problems of large difference in physical and chemical properties, large residual thermal stress of connecting parts, mismatched thermal expansion coefficients, etc., and achieves low cost, complete structure, The effect of high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

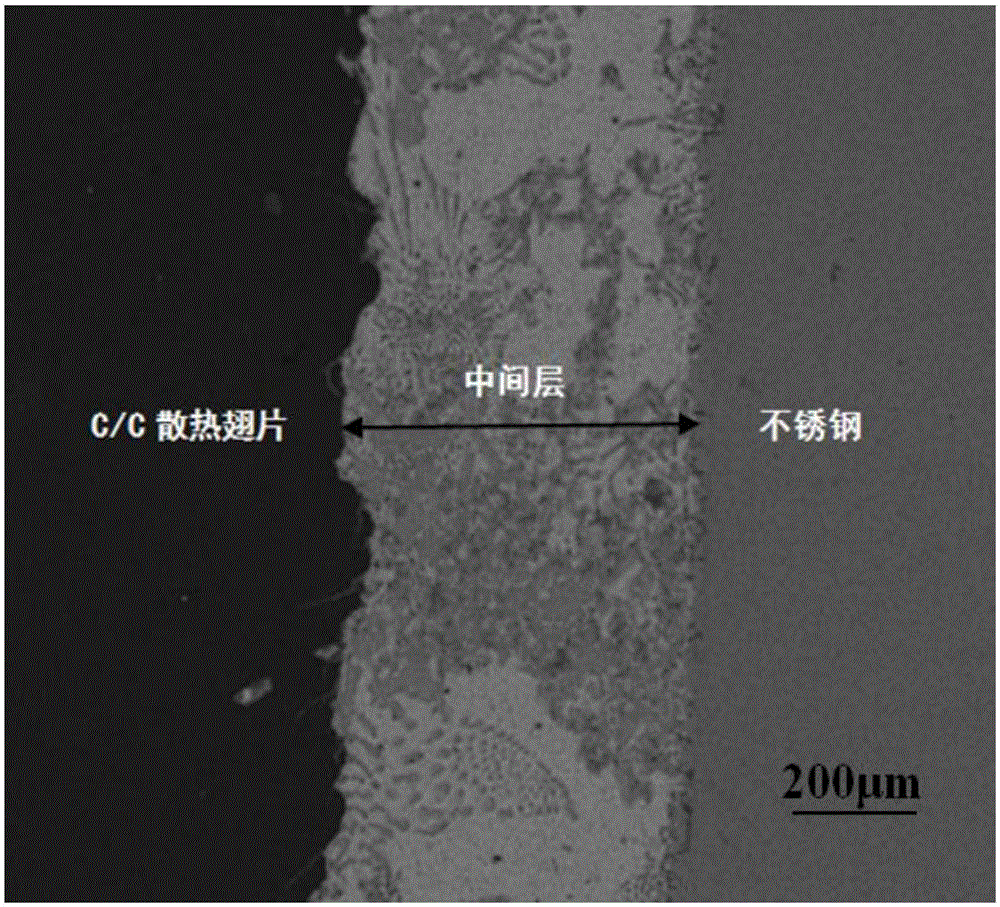

Image

Examples

Embodiment 1

[0023] (A) Pretreatment of the joining surface;

[0024] Grind and polish the surface connected to the C / C cooling fins and stainless steel pipes, and ultrasonically clean them in absolute ethanol for 30 minutes, and dry them in an oven for later use.

[0025] (B) preparation of solder;

[0026] Take the Ag powder, Cu powder and Ti powder with a particle size of 500 mesh, mix the three simple powders according to the proportion of Ag-26.7Cu-4.5Ti, add 10% alcohol, and put them into a planetary ball mill tank for mechanical ball milling. The ball milling time is 40h, and the effect of solder alloying has been achieved. After ball milling, dry the solder powder, and use paraffin wax and vaseline to prepare the dried solder powder into a slurry at a ratio of 1:1 for later use.

[0027] (C) connection process;

[0028] Apply the paste-like solder prepared in (B) above to the connection end surface of the C / C cooling fins and stainless steel tubes treated by (A), then superimpos...

Embodiment 2

[0030] (A) Pretreatment of the joining surface;

[0031] Grind and polish the surface connected to the C / C cooling fins and stainless steel pipes, and ultrasonically clean them in absolute ethanol for 30 minutes, and dry them in an oven for later use.

[0032] (B) preparation of solder;

[0033] Take the Ag powder, Cu powder and Ti powder with a particle size of 500 mesh, mix the three simple powders according to the proportion of Ag-26.7Cu-4.5Ti, add 10% alcohol, and put them into a planetary ball mill tank for mechanical ball milling. The ball milling time is 40h, and the effect of solder alloying has been achieved. After ball milling, dry the solder powder, and use paraffin wax and vaseline to prepare the dried solder powder into a slurry at a ratio of 1:1 for later use.

[0034] (C) connection process;

[0035] Apply the paste-like solder prepared in (B) above to the connection end surface of the C / C cooling fins and stainless steel tubes treated by (A), then superimpos...

Embodiment 3

[0037] (A) Pretreatment of the joining surface;

[0038] Grind and polish the surface connected to the C / C cooling fins and stainless steel pipes, and ultrasonically clean them in absolute ethanol for 30 minutes, and dry them in an oven for later use.

[0039] (B) preparation of solder;

[0040] Take the Ag powder, Cu powder and Ti powder with a particle size of 500 mesh, mix the three simple powders according to the proportion of Ag-26.7Cu-4.5Ti, add 10% alcohol, and put them into a planetary ball mill tank for mechanical ball milling. The ball milling time is 40h, and the effect of solder alloying has been achieved. After ball milling, dry the solder powder, and use paraffin wax and vaseline to prepare the dried solder powder into a slurry at a ratio of 1:1 for later use.

[0041] (C) connection process;

[0042] Apply the paste-like solder prepared in (B) above to the connection end surface of the C / C cooling fins and stainless steel tubes treated by (A), then superimpos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com