Production method and device for high-roundness glass beads

A technology of glass microspheres and production methods, applied in glass production, glass molding, glass manufacturing equipment, etc., can solve the problems of poor roundness of microbeads, easy adhesion of microbeads, ball diameter control, etc., and reduce the scrap rate , reduce adhesion, improve the effect of roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

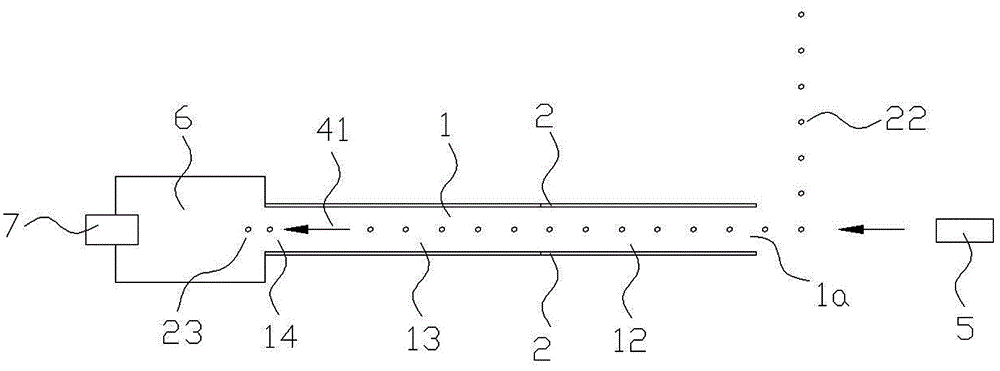

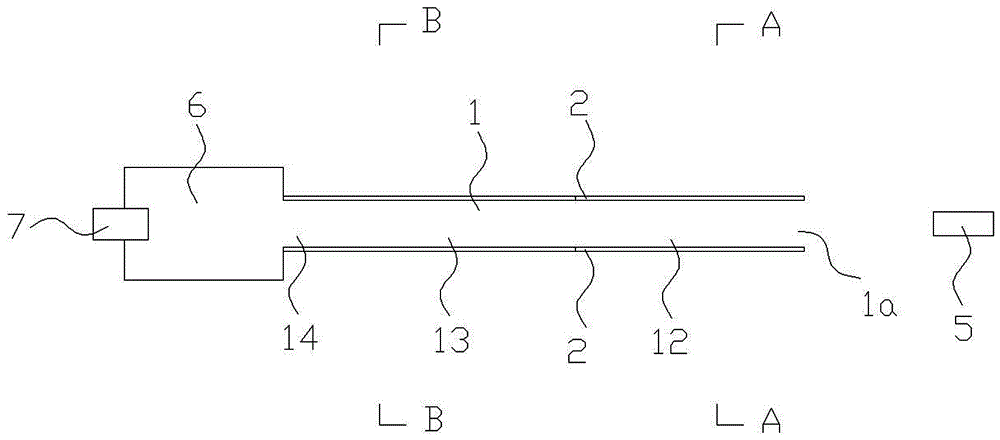

[0029] A kind of production method of high roundness glass microsphere, it is characterized in that, comprises the steps:

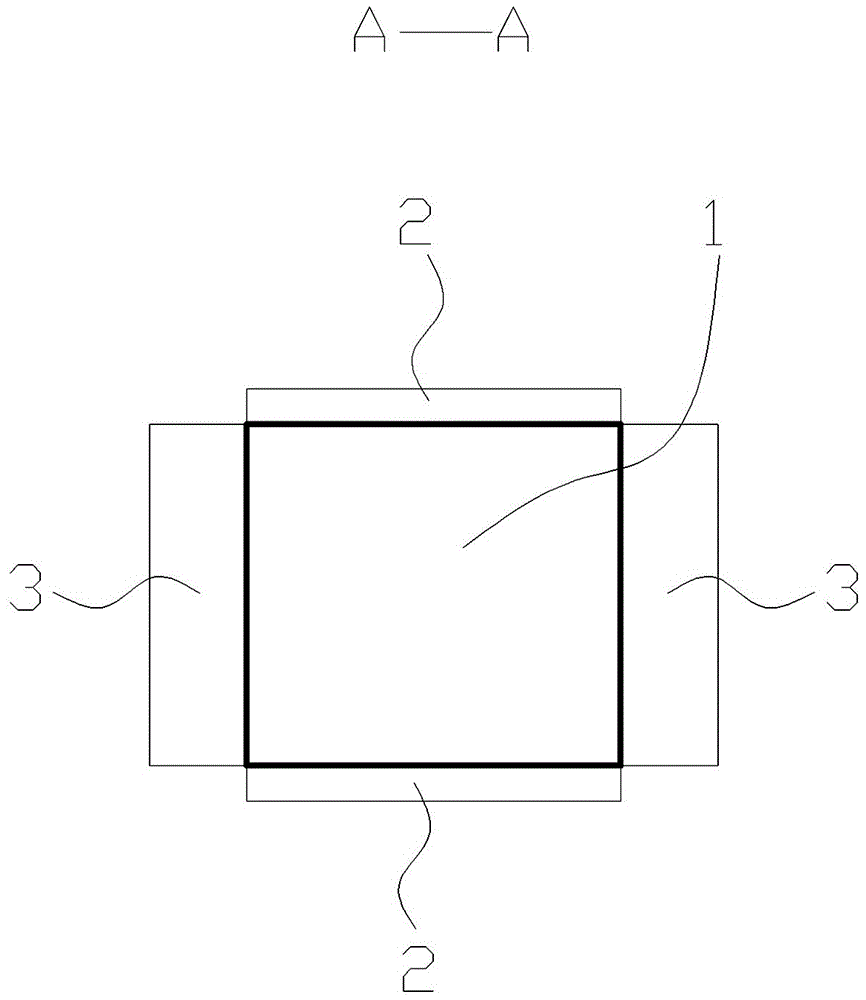

[0030] a. On the cavity of the production device, a bead zone and a cooling zone are sequentially arranged along the length direction of the cavity;

[0031] b. Generate charged glass droplets through the production device of molten glass droplets in the prior art, and then blow the charged glass droplets into the beading area in the cavity 1 through a lateral high-temperature hot air flow, and the resulting The charged glass droplets are molten and have the same diameter;

[0032] c. The charged glass droplet is suspended in the cavity by the force of the electric field, so that under the action of the air flow in the horizontal direction, the charged glass droplet in the suspended state passes through the beading zone and cooling in sequence along the horizontal direction zone, and the charged glass droplets are raised in temperature when passing throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com