Separation and reuse method of sodium sulfate from high salinity wastewater

A high-salt wastewater, sodium sulfate technology, applied in chemical instruments and methods, alkali metal sulfite/sulfate purification, water pollutants, etc. Contains toxic and harmful substances and other problems, to achieve the effect of reducing high costs, stable operation and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

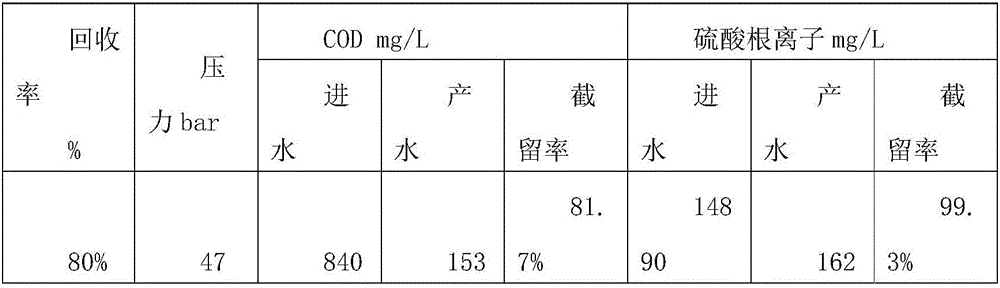

[0024] The sodium sulfate of an industrial high-salt wastewater after pretreatment is 2.2×10 4 mg / L, other about 0.3×10 4 mg / L (nitrate and ammonium salt), the high-salt wastewater 1000kg is first passed through a high-pressure nanofiltration membrane treatment device to obtain a concentrated solution of about 200kg. The concentrate contains sodium sulfate-based inorganic salts and most of the organic matter intercepted in high-salt wastewater. The organic matter is removed through advanced oxidation treatment, so that the CODcr is less than 500mg / l, and then enters the divalent salt evaporation crystallization system. During the evaporation process After the water vapor is turned into condensed water, it is used as reuse water, and about 10% of the mother liquor is returned to the front-end nanofiltration membrane treatment equipment for further separation. After crystallization, 31 kg of solid salt with a water content of about 30% was obtained, and after drying, 21.8 kg of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com