Tire pressure monitoring system for single-track train

A tire pressure monitoring system, a technology for monorail trains, applied in tire measurement, vehicle parts, tire parts, etc., can solve the problem of trains without tire pressure alarm function, there are safety risks, and it is difficult to realize real-time monitoring, early warning and system fault self-diagnosis and other problems, to achieve the effect of preventing train safety accidents and improving safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be described clearly and in detail below with reference to the drawings in the embodiments of the present invention. The described embodiments are only some of the embodiments of the invention.

[0021] Technical scheme of the present invention is as follows:

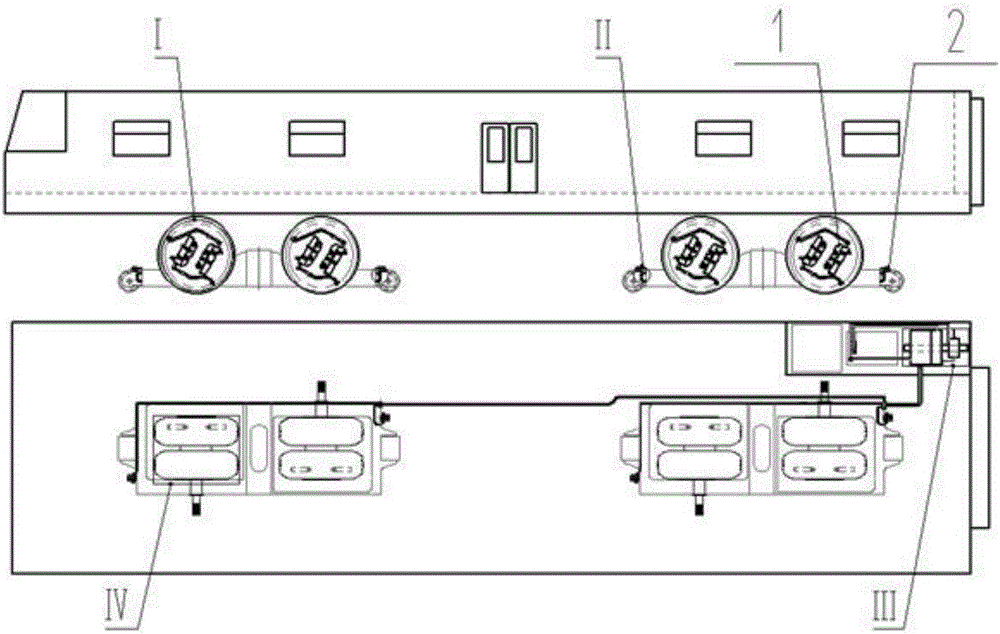

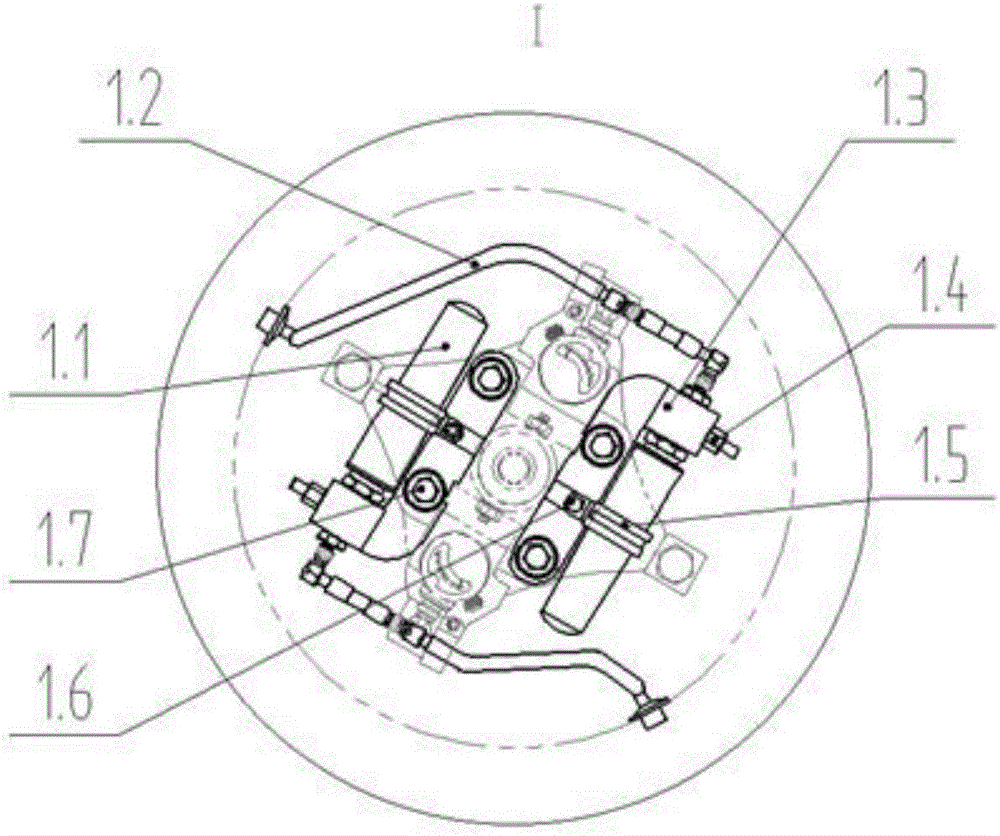

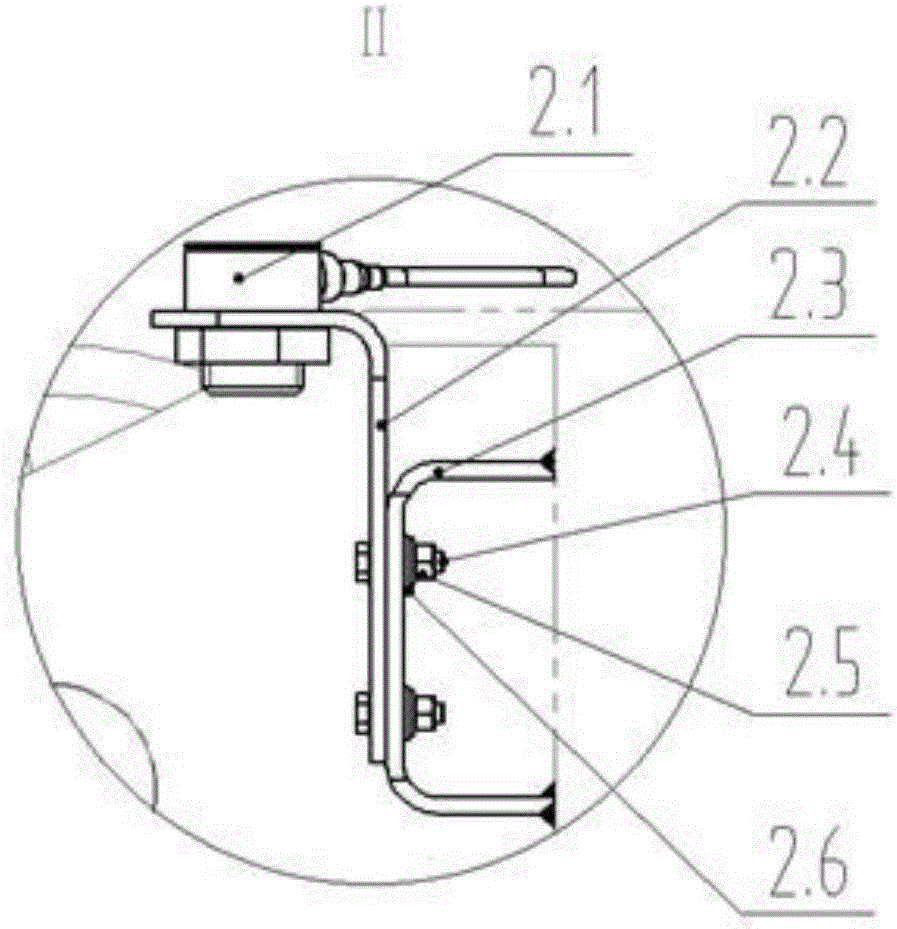

[0022] Such as Figure 1-6 Shown is a new type of monorail train tire pressure monitoring system with high safety and reliability provided by the present invention, which has a wireless tire pressure monitoring system. The monitoring system adopts a distributed measurement and control network architecture. These include the wireless tire pressure monitoring network architecture of the running wheels and the training wheel height monitoring network architecture.

[0023] The wireless tire pressure monitoring network architecture of the running wheels uses one vehicle as an independent monitoring unit, and monitors the air pressure inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com