Production process of precision mold

A production process and precision mold technology, applied in the field of mold manufacturing, can solve the problems of poor control of processing parameters, poor surface quality, low dimensional accuracy, etc., and achieve the effect of simple and controllable production process operation and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

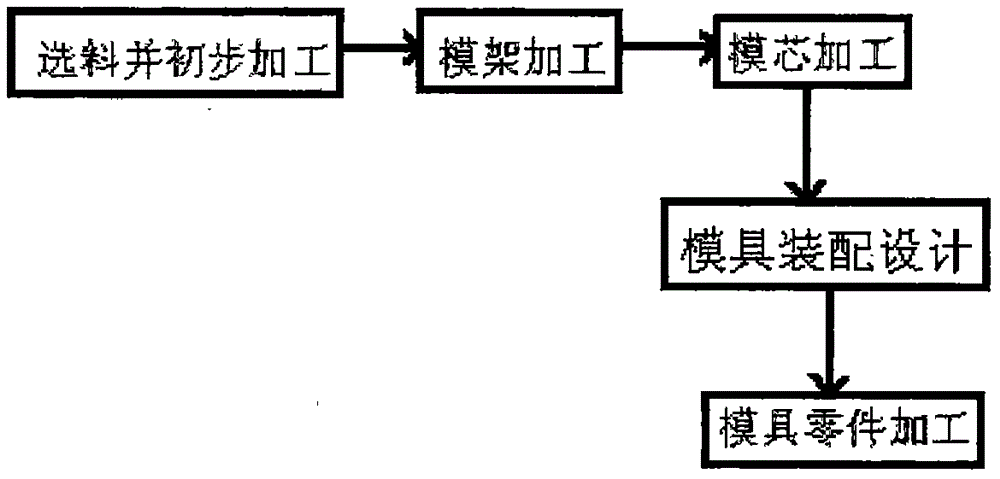

[0020] The technical scheme that the present invention adopts to solve its technical problem is: a kind of precision mold production process, it comprises the following steps:

[0021] A precision mold production process, said process comprising the steps of: (1) sieving, and preliminary processing; (2) mold shelf design, which includes plate surface processing, thimble fixing plate processing, and bottom panel processing; (3) Core design, which includes flashing, rough grinding, milling machine processing, fitter processing, and rough machining; (4) Mold assembly design: carry out upper mold and lower mold assembly, complete the cooperation between the stopper and the positioning pin, and finally use the fastening Tighten the bolts; process the positioning reference hole for the mated mold, the surface roughness of the hole should be higher than Ra0.8; the upper mold core is processed by inlay welding, and the core rod is processed by cylindrical grinding. The core head is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com