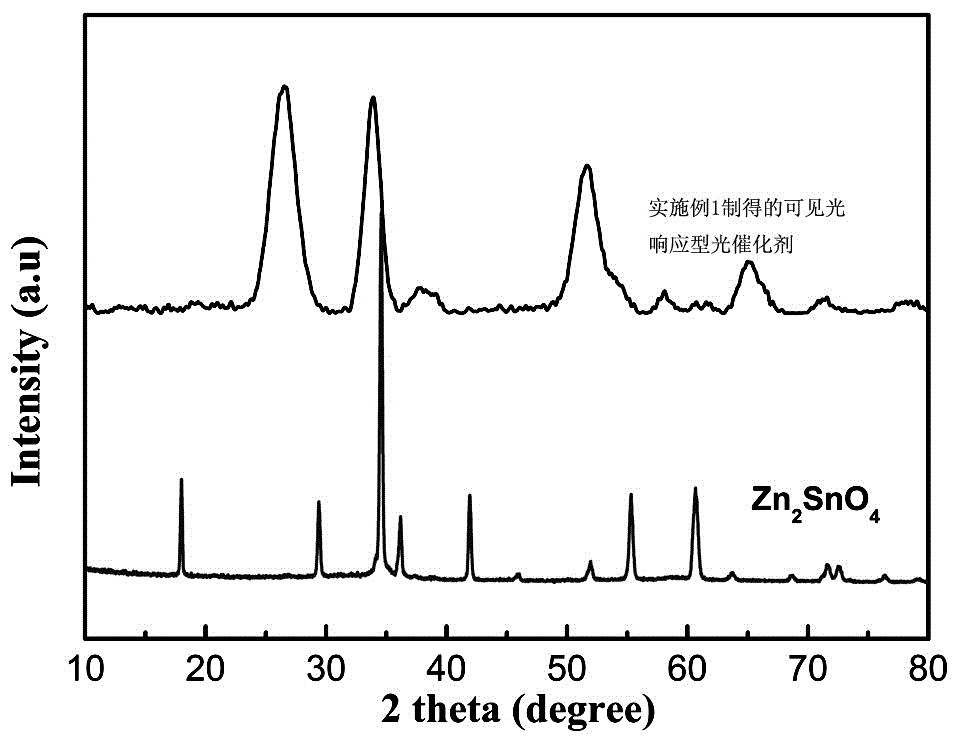

Method for preparing visible-light response photocatalyst by utilizing nano Zn2SnO4

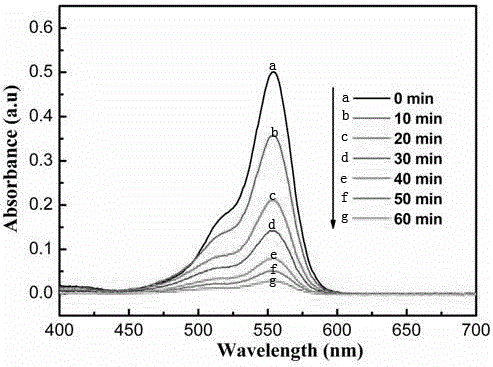

A photocatalyst and visible light technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of low recombination probability of photogenerated electrons and holes The problems of low electron mobility and high quantum efficiency achieve excellent photocatalytic performance, simple synthesis process, and shortened migration distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

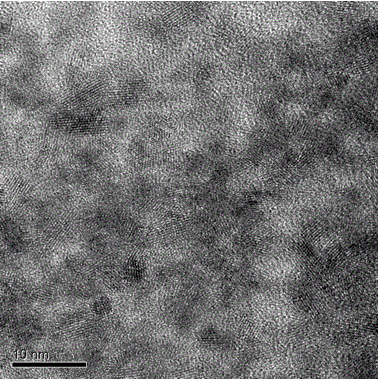

Embodiment 1

[0024] Nano Zn 2 SnO 4 The method for preparing a visible light-responsive photocatalyst comprises the following steps: step 1, taking a certain amount of sodium hydroxide powder, dissolving it completely in a solvent, stirring and dissolving to prepare a NaOH solution with a concentration of 3.75mol / L , marked as solution A, for subsequent use; wherein the solvent used is deionized water;

[0025] Step 2, take a certain amount of tin tetrachloride and zinc chloride and dissolve in the solvent to form a mixed solution, fully stir and dissolve the Sn in the mixed solution prepared 4+ with Zn 2+ Concentrations are 0.25mol / L and 0.5mol / L respectively, marked as mixed solution B, standby; wherein the solvent used is deionized water;

[0026] Step 3: Take 2 parts of solution A prepared in step 1 and 1 part of mixed solution B prepared in step 2 in parts by volume, and add the measured solution A at a rate of 2 mL / min to In the mixed solution B, the suspension is obtained after ...

Embodiment 2

[0034] Nano Zn 2 SnO 4 The method for preparing a visible light-responsive photocatalyst comprises the following steps: step 1, taking a certain amount of sodium hydroxide powder, dissolving it completely in a solvent, stirring and dissolving to prepare a NaOH solution with a concentration of 3.75mol / L , marked as solution A, for subsequent use; wherein the solvent used is deionized water;

[0035] Step 2, take a certain amount of tin tetrachloride and zinc chloride and dissolve in the solvent to form a mixed solution, fully stir and dissolve the Sn in the mixed solution prepared 4+ with Zn 2+ Concentrations are 0.25mol / L and 0.5mol / L respectively, marked as mixed solution B, standby; wherein the solvent used is deionized water;

[0036] Step 3: Take 2 parts of solution A prepared in step 1 and 1 part of mixed solution B prepared in step 2, in parts by volume, and add the measured A solution to the In the mixed solution B, the suspension is obtained after full reaction, an...

Embodiment 3

[0042] Nano Zn 2 SnO 4 The method for preparing a visible light-responsive photocatalyst comprises the following steps: step 1, taking a certain amount of sodium hydroxide powder, dissolving it completely in a solvent, stirring and dissolving to prepare a NaOH solution with a concentration of 3.75mol / L , marked as solution A, for subsequent use; wherein the solvent used is deionized water;

[0043] Step 2, take a certain amount of tin tetrachloride and zinc chloride and dissolve in the solvent to form a mixed solution, fully stir and dissolve the Sn in the mixed solution prepared 4+ with Zn 2+ Concentrations are 0.25mol / L and 0.5mol / L respectively, marked as mixed solution B, standby; wherein the solvent used is deionized water;

[0044] Step 3: Take 2 parts of solution A prepared in step 1 and 1 part of mixed solution B prepared in step 2, in parts by volume, and add the measured A solution to the In the mixed solution B, the suspension is obtained after full reaction, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com