A long-term fluidized aerosol generating device with self-dispersion function

An aerosol generation and self-dispersion technology, applied in aerosol preparation, colloid chemistry, colloid chemistry, etc., can solve problems such as poor fluidity, difficulty in powder supply, and easy condensation, so as to improve efficiency and stability, and ensure long-term The effect of time operation and prevention of air stagnation zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

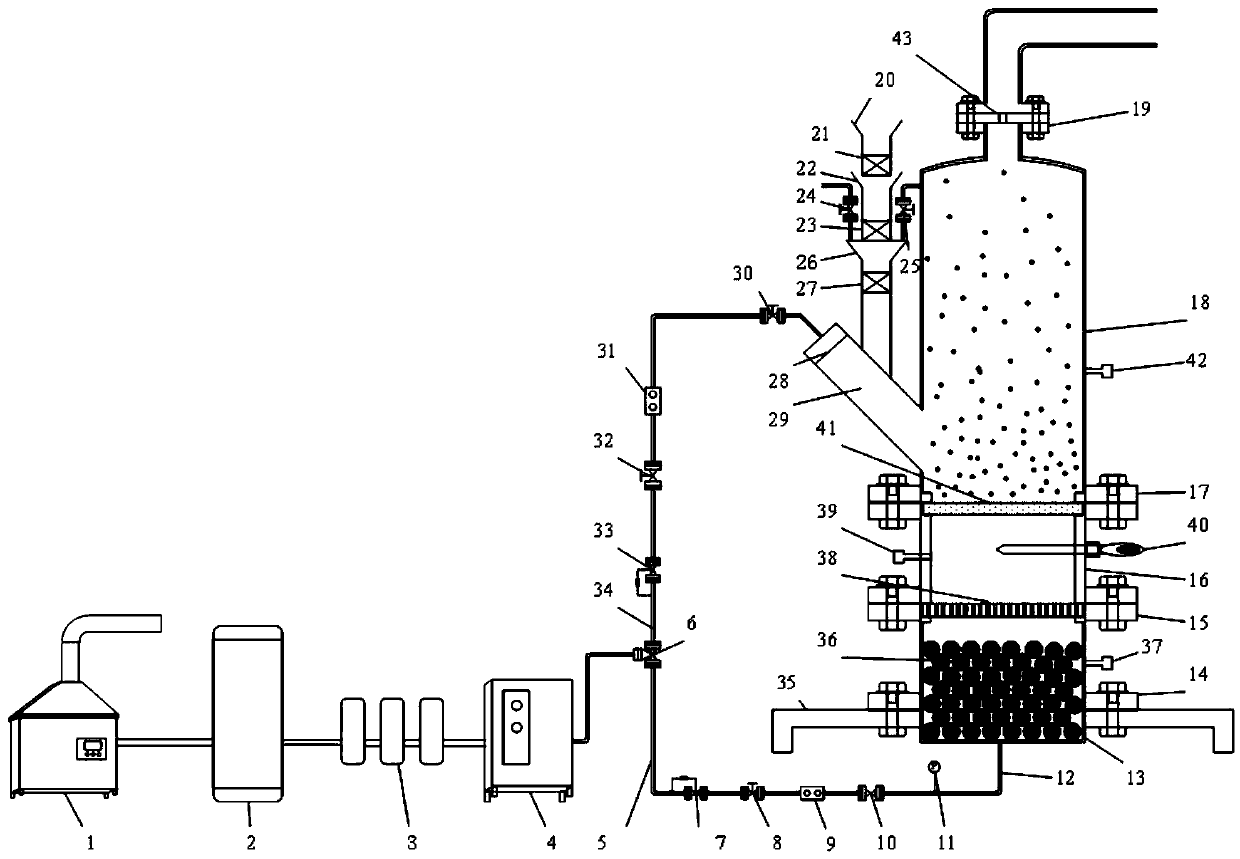

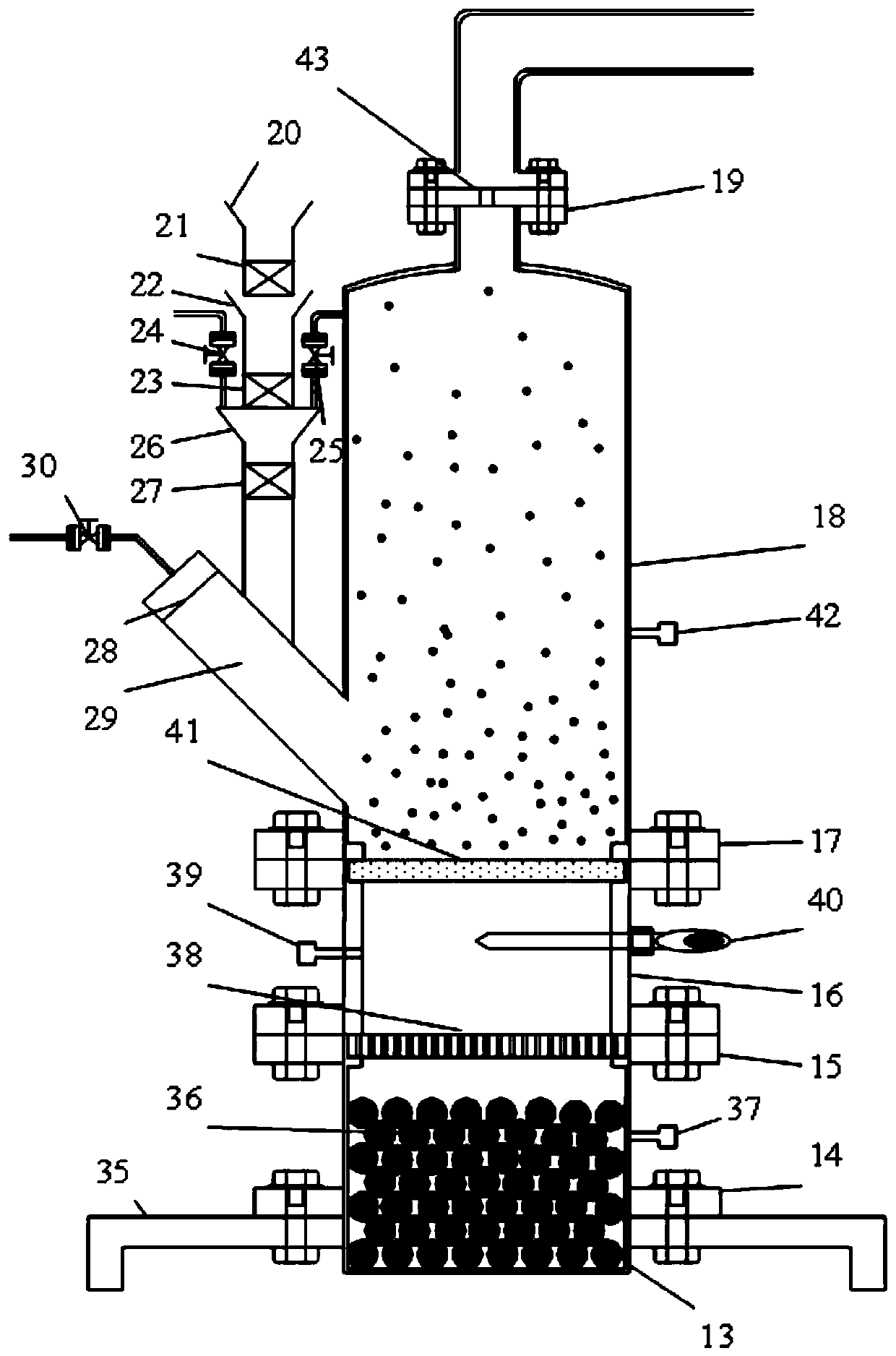

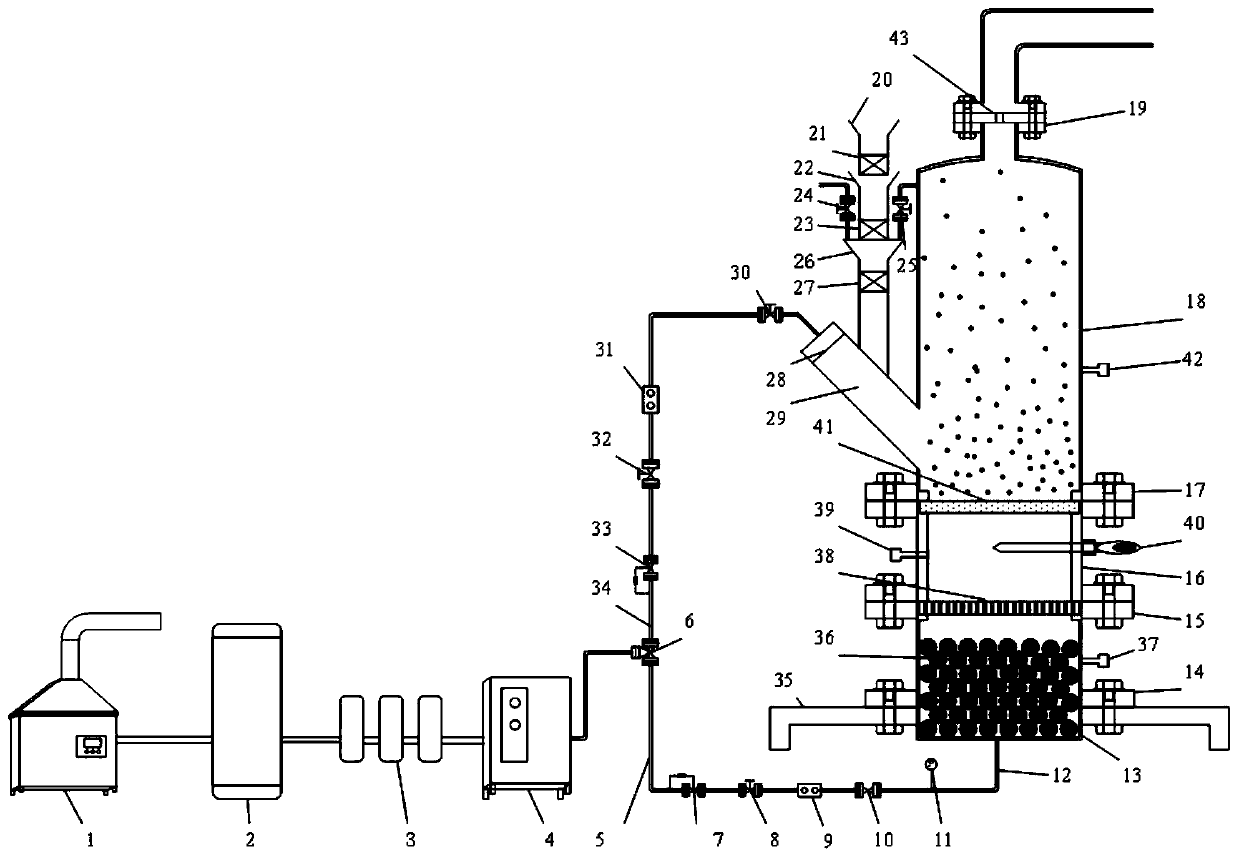

[0014] combine Figure 1~2 , The present invention provides a long-term fluidized aerosol generating device with self-dispersing function. The aerosol generating device is composed of an airflow supply part, an airflow drying part, a powder boiling fluidization part, a powder self-dispersing part and a powder online continuous supply part.

[0015] The air supply part is mainly composed of a compressor 1, an air storage tank 2, a gas filter 3, a cold dryer 4, a pressure reducing valve 7 and 33, a shut-off valve 8 and 32, a flow meter 9 and 31, a flow regulating valve 10, a supplementary The gas pipeline 34 and the gas supply valve 30 are composed of a stable gas source with a certain pressure and flow rate for the aerosol generating device.

[0016] The airflow drying part is composed of a drying cylinder 13, a desiccant 36, an equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com