Plate-shaped corrugated membrane diaphragm having uniform aperture and preparation method thereof

A technology of corrugated membrane and diaphragm, which is applied in the field of plate-shaped corrugated membrane and its preparation, can solve the problems of hydrophilic performance, poor pore size uniformity, low filling area, hindering the development of the membrane industry, etc., and achieve good comprehensive performance and good pore size The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

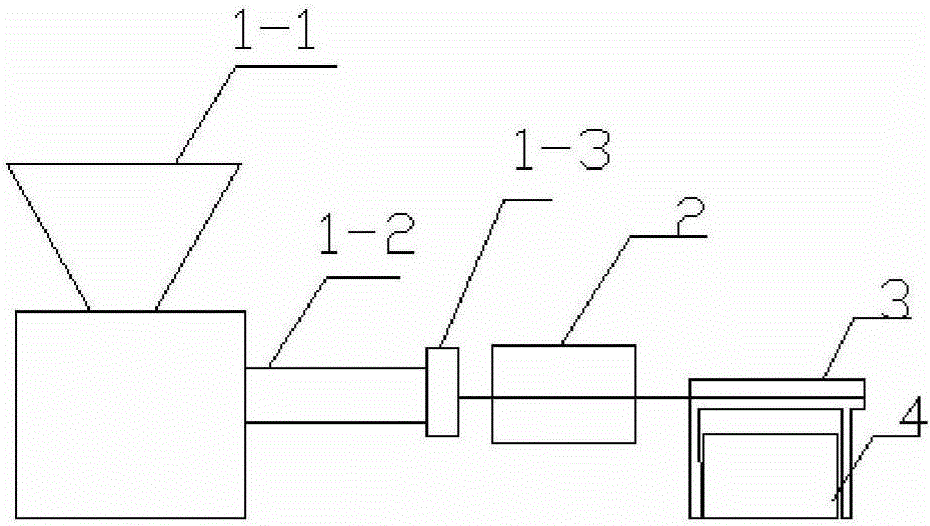

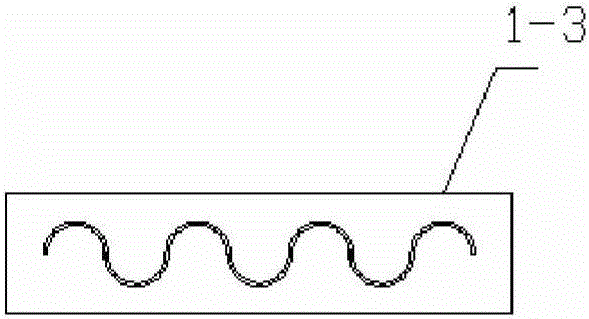

[0045] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a method for preparing a plate-shaped corrugated film membrane with uniform apertures comprises the following steps: adopting a plate-shaped film with a corrugated form, including a high-energy radiation etching step, a PET extrusion molding step and an imprinted radiation hole-forming step;

[0046] The PET extrusion molding step adopts the form of extruding PET to form a special-shaped diaphragm, and the formation of uniform holes is completed on the special-shaped diaphragm by using the nuclear pore membrane forming process step;

[0047] The imprinting radiation hole forming step includes a high energy radiation etching step;

[0048] Finally, a corrugated PET film with uniform pore size is prepared.

[0049] The PET material corrugated plate membrane can effectively prevent the membrane from sticking during operation. The hydrophilicity of the PET material body is...

Embodiment 2

[0055] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a method for preparing a plate-shaped corrugated membrane diaphragm with a uniform aperture comprises the following steps;

[0056] Step 1. Dry the PET raw material first, turn on the extruder 1, add the dry PET raw material into the feed port 1-1, pass through the extrusion mixing conveying section, and extrude the diaphragm of the required shape from the extrusion nozzle 3 .

[0057] Among them, the moisture content of PET raw materials needs to be controlled at 0.001-0.01%;

[0058] The temperature control preheating section is between 150-200 degrees, the conveying section is between 180-260 degrees, and the extrusion section is between 240-300 degrees;

[0059] Adjust the extrusion speed and traction speed to obtain a PET sheet with a thickness of 5-200 μm;

[0060] The corrugation height H of the extruded diaphragm is 0.5-5mm, and the length L is 0.5-10mm.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com