A protective steel wire dividing mechanism for rock climbing

A technology of steel wire and wire wheel, which is used in mountaineering equipment and sports accessories, etc., can solve problems such as safety accidents, mutual interference, and ground congestion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

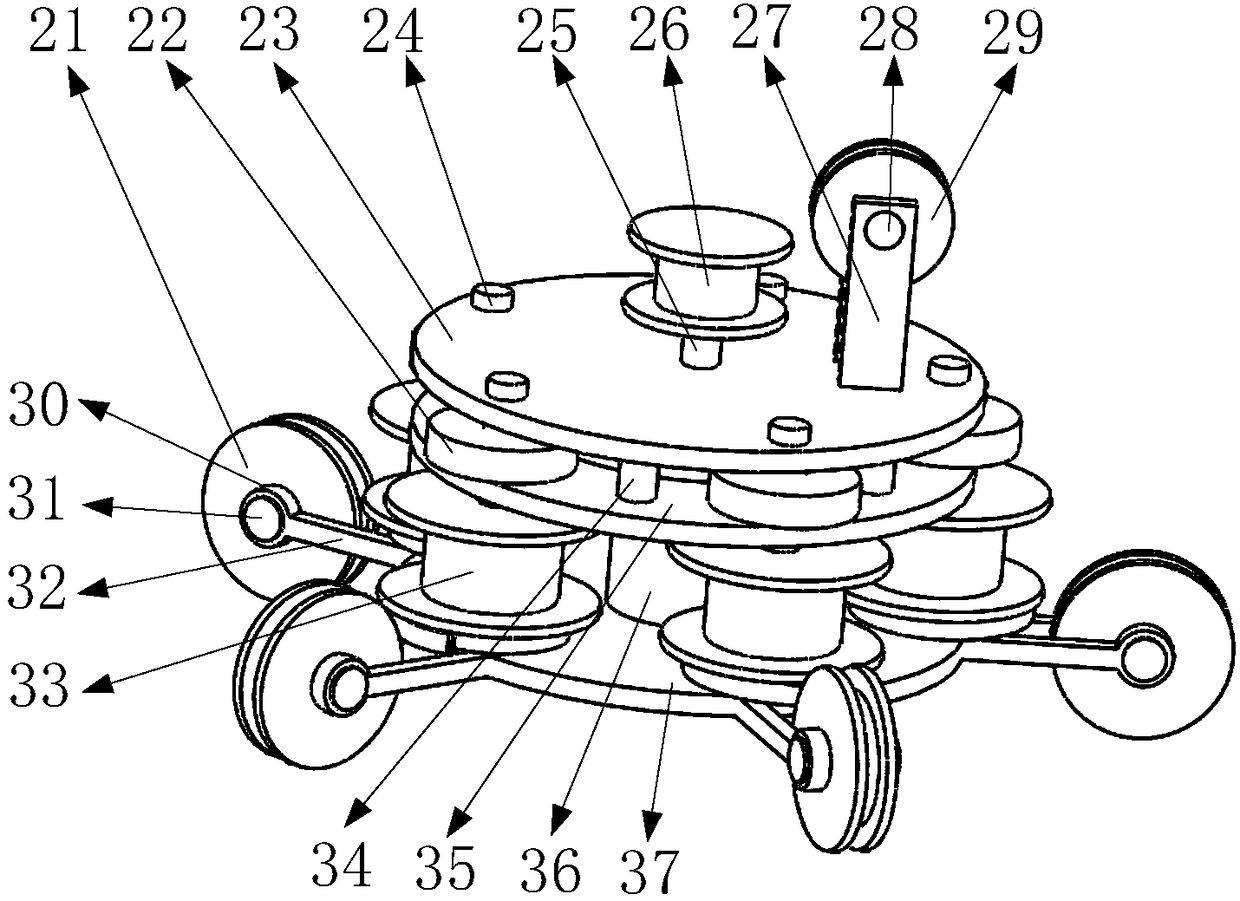

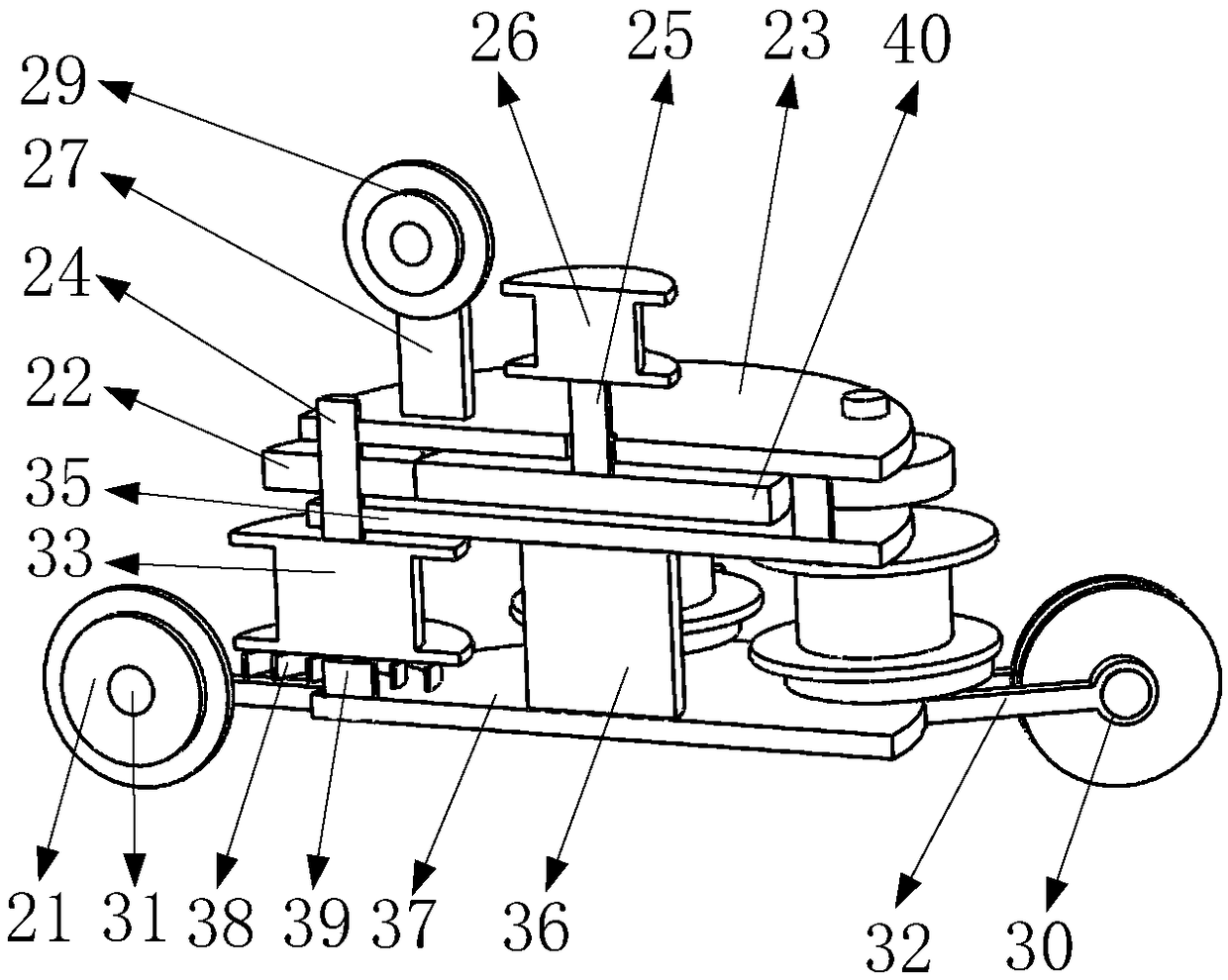

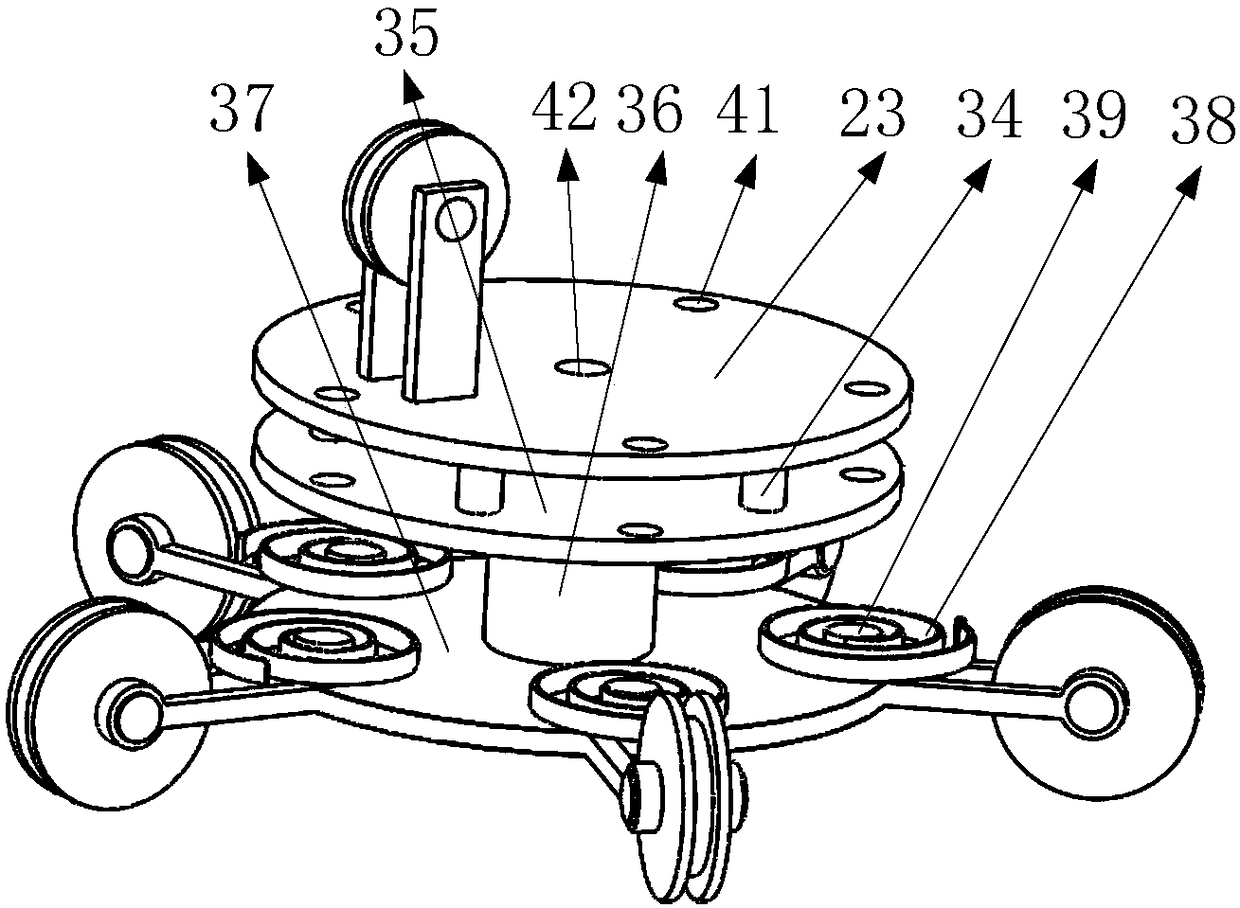

[0017] like figure 1 , 2 As shown, it includes the first pulley, external gear, first fixed plate, first shaft, second shaft, second wire wheel, second pulley support, second pulley shaft, second pulley, bushing, first pulley Rotating shaft, first pulley support, first wire wheel, first fixed column, second fixed plate, second fixed column, third fixed plate, scroll spring, scroll spring fixed column, central gear, first shaft hole, The second rotating shaft hole, the scroll spring fixing structure, such as image 3 As shown, the first fixed plate is evenly opened with five first shaft holes in the circumferential direction, and the second shaft hole is opened in the middle, and the second fixed plate is installed on the first fixed column through five first fixed columns evenly distributed in the circumferential The lower side of the plate, and the second fixed plate has five first shaft holes corresponding to the first fixed plate; the five first fixed columns are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com