Transfer needle for a knitting machine

A technology of transfer needles and knitting machines, which can be used in knitting, textiles and papermaking, and can solve the problems of high-tech costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

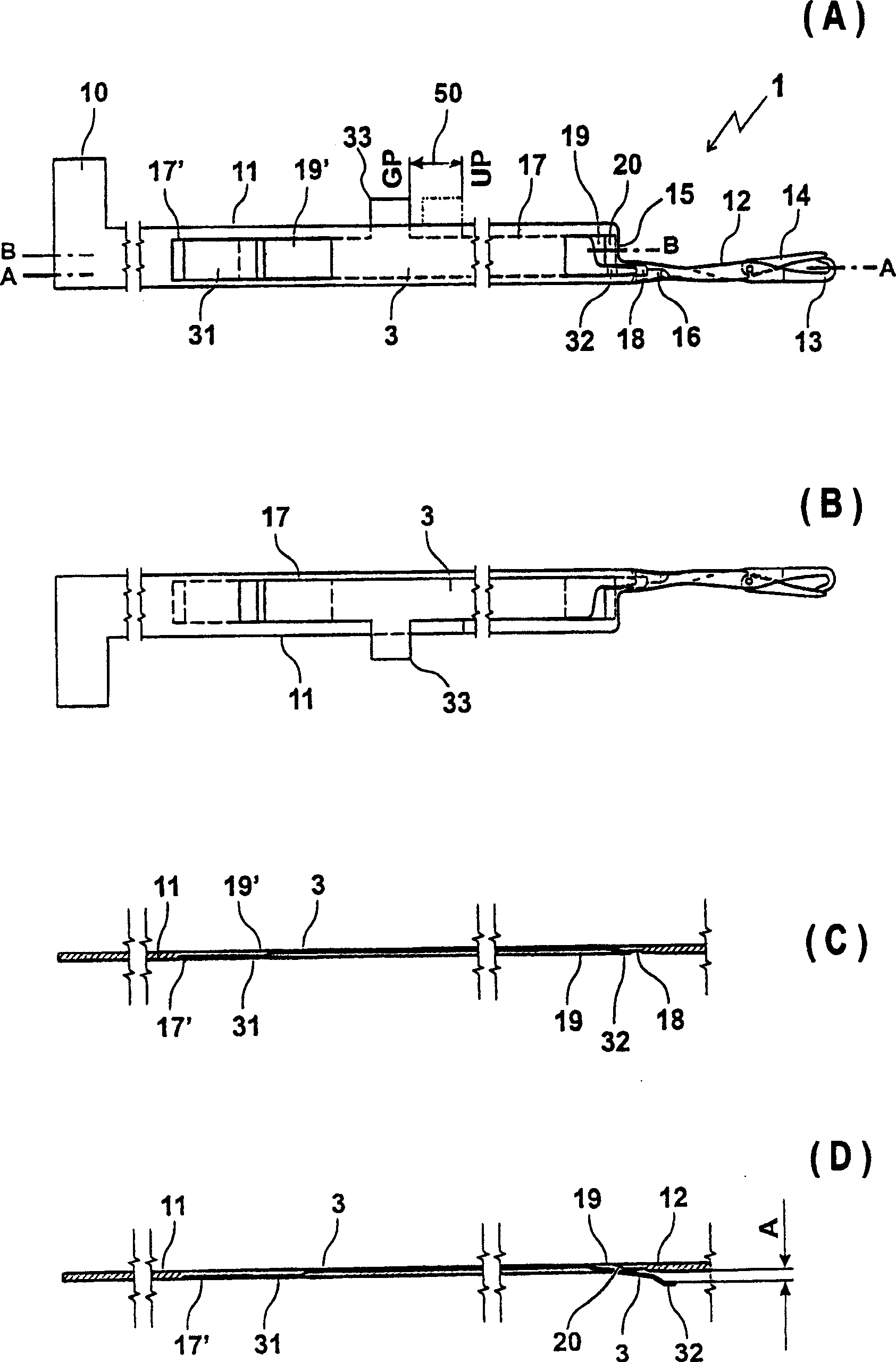

[0019] Depend on figure 1 a) It can be seen that the transfer needle 1 has a transfer spring 3 guided in the needle body 11, which is movable in the longitudinal direction of the needle body 11 from its base position GP to its transfer position in one direction of the double arrow 50. The circle position UP can be returned to its base position GP in the other direction.

[0020] The needle neck 12 , needle hook 13 , tongue 14 , needle belly 15 and recess 16 of the transfer needle 1 largely correspond to transfer needles with known hard box-type transfer springs.

[0021] The needle body 11 is provided with a groove 17 along the longitudinal side, and the depth and height of the groove are designed so that the groove forms a guiding device and a sliding surface for the transfer spring 3 .

[0022] At the end of the needle body 11 formed by the needle belly 15 , the groove 17 has a perforation 19 over its entire height, which ends with a bevel 20 towards the needle belly 15 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com