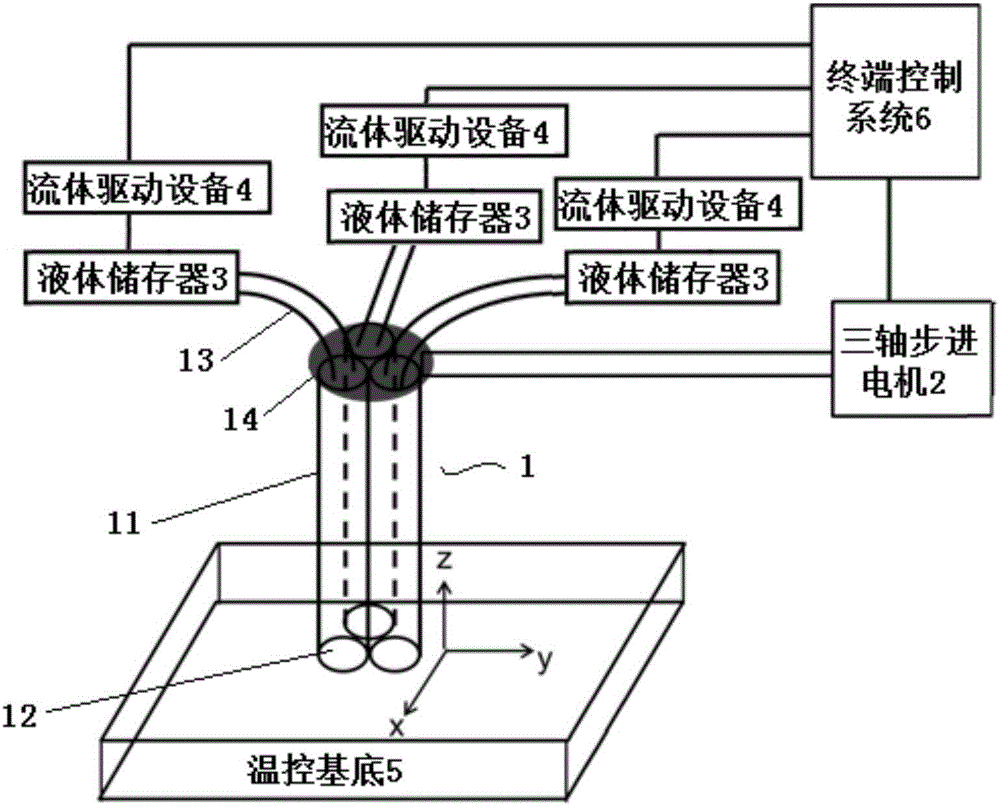

Multicomponent three-dimensional organism printing device and method based on multi-channel nozzle

A technology of three-dimensional biology and printing devices, which is applied in medical science, prosthesis, additive processing, etc., can solve problems such as limited application, limited cell survival rate, high solution viscosity, and high surface tension, and achieves broad application prospects. The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

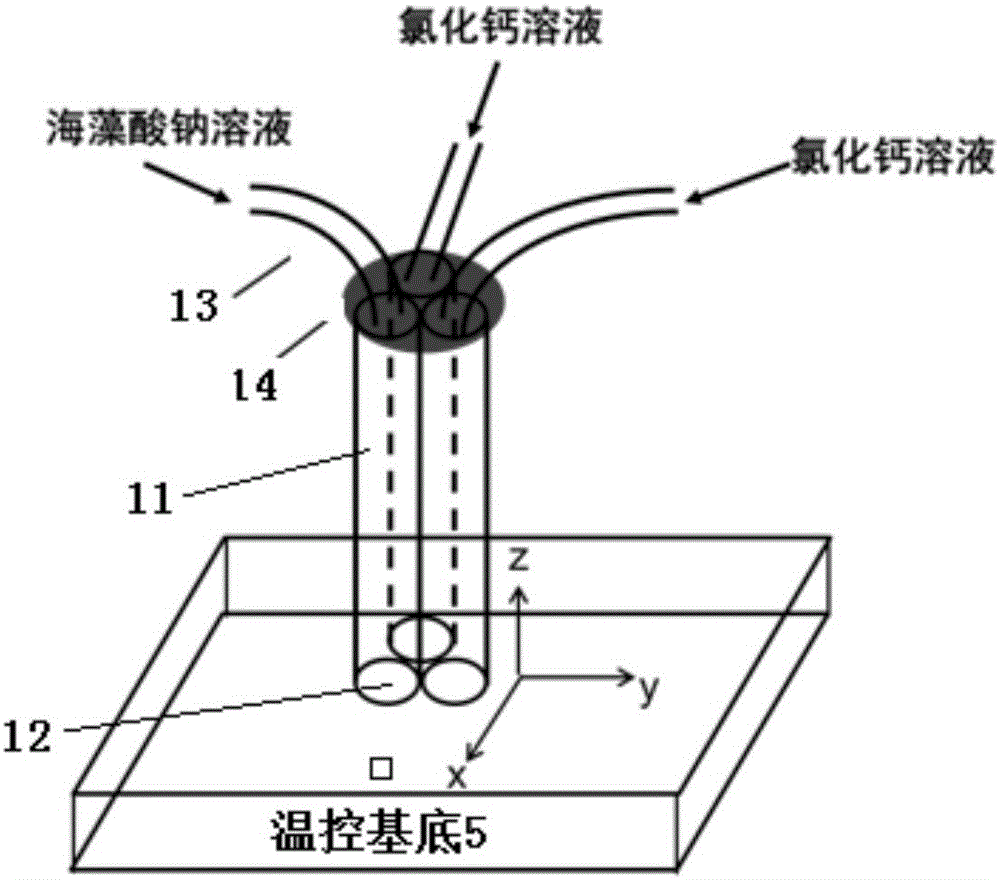

[0040] like figure 2 Shown is a schematic diagram of the device of the three-channel nozzle provided in Example 1 of the present invention. In this embodiment, three glass capillaries are arranged side by side to form a multi-channel nozzle 1 , and the inner diameters of the glass capillaries are all 500 μm. Each glass capillary top uses Teflon tube 13 and liquid reservoir 3 ( figure 2 (not shown in ) and sealed with paraffin 14. The No. 1 ink that the present embodiment selects is the sodium alginate solution that the mass fraction is 5%; No. 2 and No. 3 inks are the calcium chloride (CaCl 2 ) aqueous solution.

[0041] After connecting the liquid channels respectively, the multi-channel nozzle 1 is fixed on the three-axis stepping motor 2, and the z-axis height is adjusted so that the distance between the multi-channel nozzle 1 and the printing substrate is less than 1mm. Start the printing program, set the printing speed to 20mm / s, and the liquid injection speed to 0....

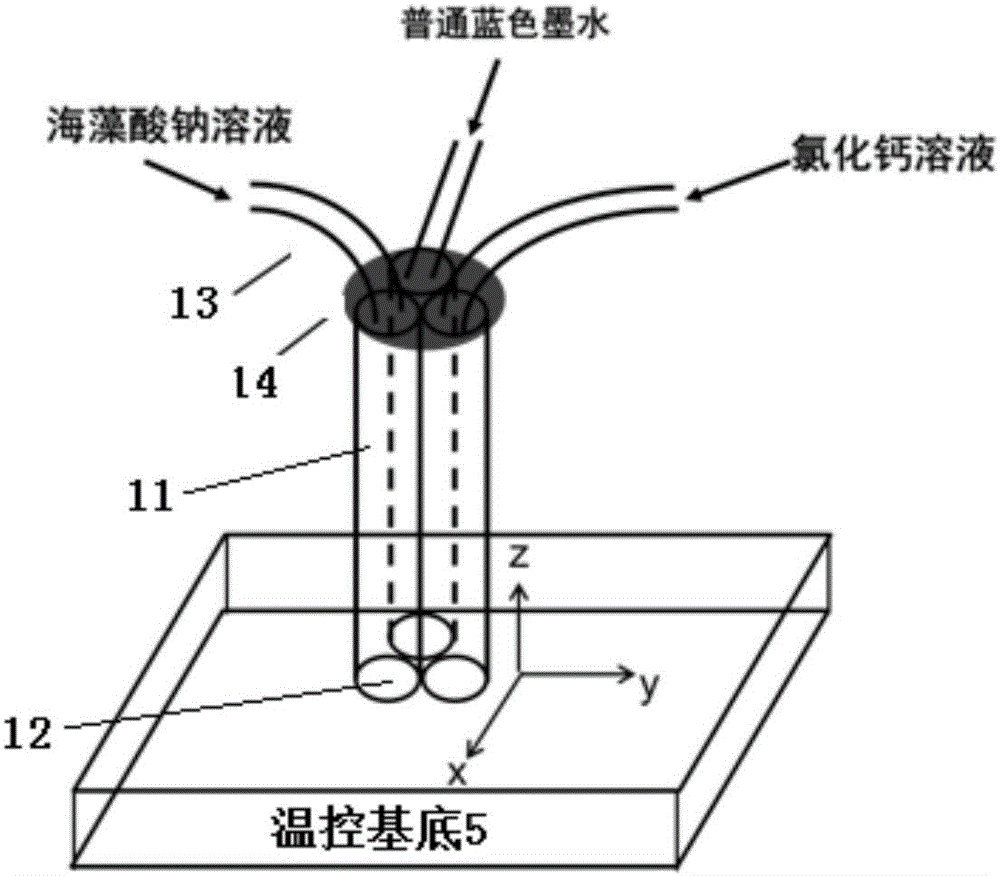

Embodiment 2

[0043] like image 3 As shown, changing the No. 3 ink in Example 1 to ordinary blue ink, and printing with other parameters unchanged, a piece of blue gel can be printed, similarly, a variety of different gels can be mixed at different positions Ink, print out colored gel.

Embodiment 3

[0045] like Figure 4 As shown, the No. 3 ink in Example 1 was replaced with rat aortic endothelial cell suspension, and printing was performed with the same parameters, and a gel evenly loaded with cells could be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com