A dry-type transformer box structure

A dry-type transformer and box structure technology, applied in transformer/inductor cooling, transformer/inductor shell, transformer/inductor components, etc., can solve the problem of inconvenient transportation and loading and unloading, slow assembly speed, and no telescopic structure and other problems, to achieve the effect of easy transportation, loading, unloading and storage, optimizing the heat dissipation effect, and good ventilation and heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

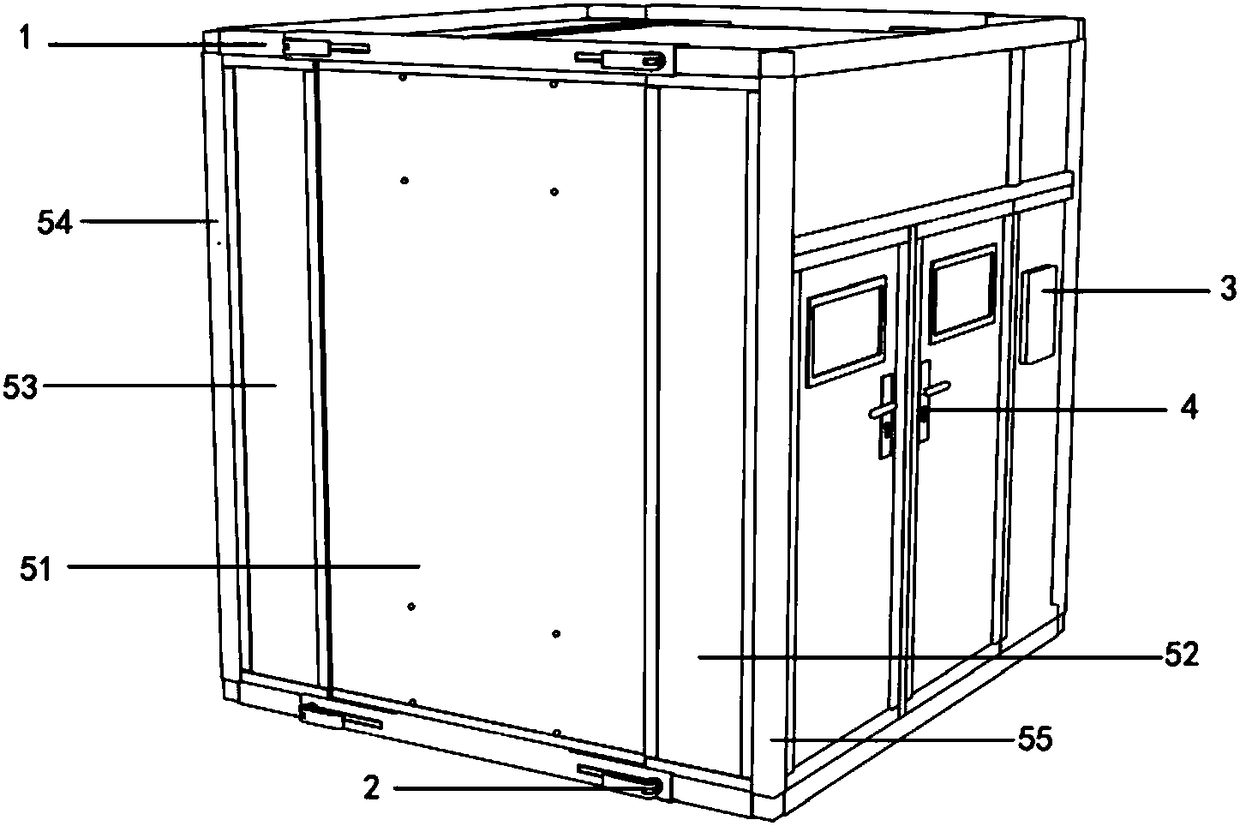

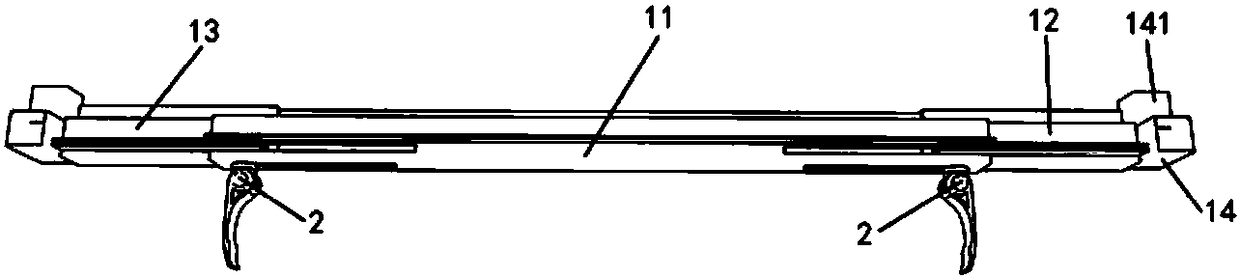

[0022] Such as figure 1 As shown, the dry-type transformer box structure of the present invention is a cuboid or a cube, including twelve supporting frames, and the plates forming the six sides of the box are correspondingly fixed to the supporting frames. Among them, the four sides of the left side, the right side, the top side and the bottom side are scalable, the left side and the top side, the left side and the bottom side, the right side and the top side, and the right side and the bottom side. The support frame shared by the end faces adopts a telescopic structure. The plates on these four sides expand and contract with the expansion and contraction of the support frame, so that the overall volume of the box structure can be adjusted, which is convenient for transportation to the transformer after assembly in the factory and other places. Use location for installation. The state of the box after shrinkage is as follows figure 2 shown.

[0023] Now take the left side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com