Inverted V-shaped plate sedimentation device

A technology of sedimentation device and wing plate, applied in the direction of sedimentation tank, etc., can solve the problems of large space occupied by water inlet and outlet, affecting sedimentation effect, increasing sedimentation load, etc., achieving adjustable tank height, good sedimentation effect, and buffering of inlet and outlet water. area reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described in conjunction with the accompanying drawings and examples.

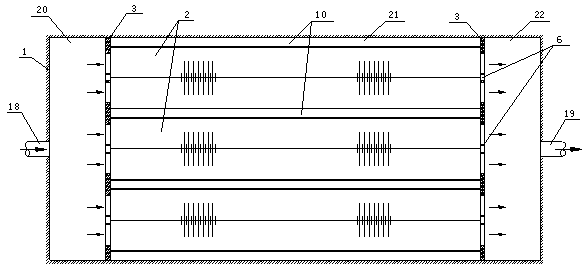

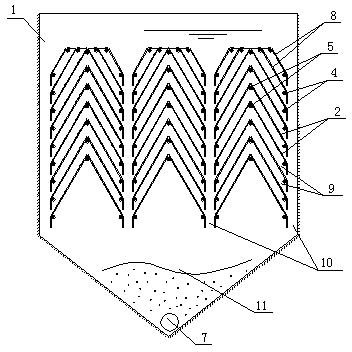

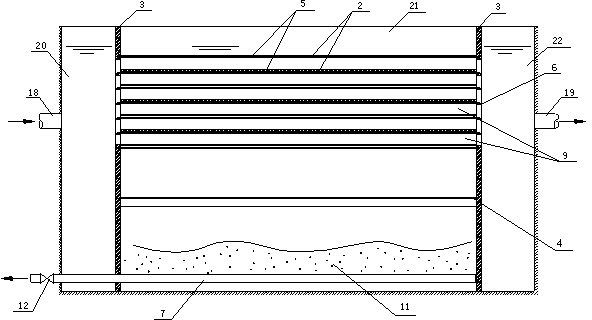

[0019] The inverted V-shaped plate sedimentation device is composed of a pool 1 and an inverted V-shaped plate 2 installed in the pool, a sealing plate 3, a side beam 4, a spine 5, a spine bracket 6, a mud discharge pipe 7, an inlet pipe 18, and an outlet pipe 19. . The plane of the pool 1 is rectangular, the side walls are upright, and the bottom is conical. One end of the pool wall is provided with a water inlet pipe 18, and the other end of the pool wall is provided with an outlet pipe 19. Two sealing plates 3 are used to divide the pool 1 into a water inlet area 20 , a sedimentation area 21 and a water outlet area 22 .

[0020] The two sides and the bottom edge of the sealing plate are fixed with the pool wall.

[0021] An inverted V-shaped plate 2 is set in the precipitation area 21 between the two sealing plates 3, the inverted V-shaped plate 2 is perpendicu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com