Method and system for preventing jamming of drilling tool

A sticking and suspended weight technology, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc., can solve the problems of equipment damage, cost increase, and drilling speed reduction, so as to avoid equipment damage and prevent sticking , The effect of accelerating the drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

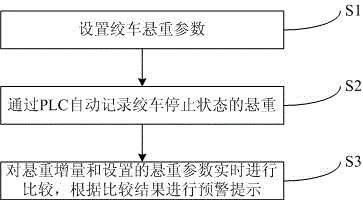

[0021] Such as figure 1 As shown, a method for preventing drill sticking, the steps of the method are as follows:

[0022] S1. Set the winch suspension weight parameters;

[0023] S2. Automatically record the suspension weight of the winch stop state through PLC;

[0024] S3. Comparing the suspension weight increment and the set suspension weight parameter in real time, and giving an early warning prompt according to the comparison result.

[0025] The suspended weight parameters include the lifting limit value of the suspended weight and the lowering limit value of the suspended weight.

[0026] Said suspension weight increment = suspension weight in stop state - suspension weight in real time - overweight value generated by acceleratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com