On-site construction system and method of pile foundation based on 3D printing

A 3D printing and on-site construction technology, which is applied in the direction of infrastructure engineering, sheet pile walls, manufacturing tools, etc., can solve the problems of difficult control of pile body quality, difficulty in one-time molding, and secondary construction, so as to save concrete materials, Retain the effect of convenience and strong customization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

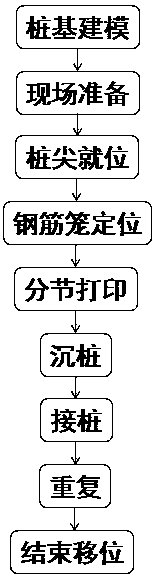

[0037] Taking the design and construction requirements of a certain pile foundation as an example, a number of prefabricated pipe piles are made and constructed according to the project needs and used as storage wells. The pile length is 18m, the pile outer diameter is 1200mm, and the inner diameter is 1000mm. Soft soil, groundwater is located 5m below the ground. Adopt construction system and method of the present invention to carry out construction now.

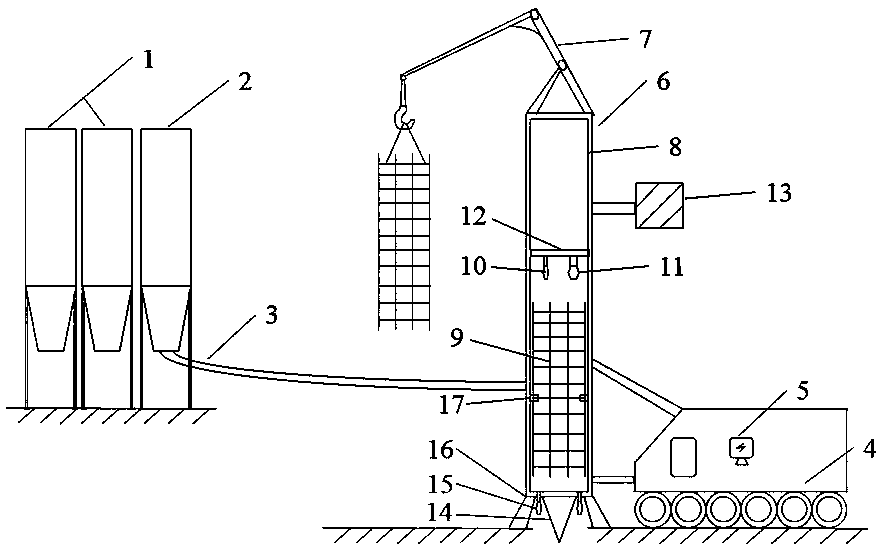

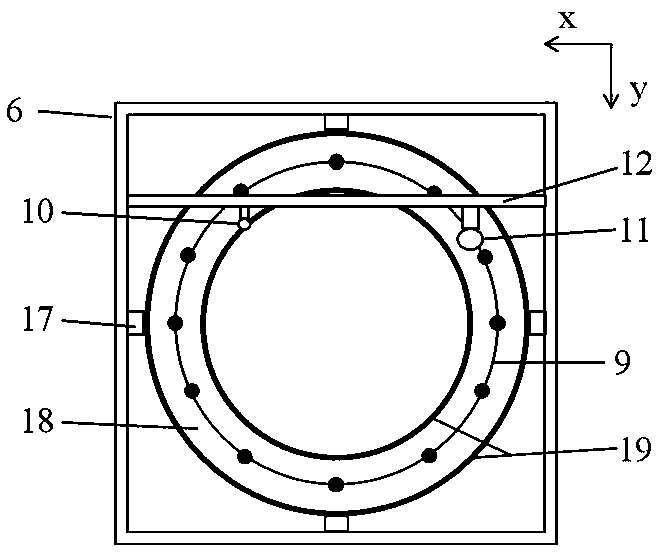

[0038] The on-site construction system and method of pile foundation based on 3D printing in this embodiment are as follows: figure 1 As shown, it includes: batching tank 1, consumable tank 2, feeding pipe 3, ground running mechanism 4, computer control host 5, guide frame 6, boom 7, slide rail 8, steel cage 9, printing nozzle 10, pouring nozzle 11. OXYZ printing support 12, heavy hammer 13, prefabricated pile tip 14, high-pressure water gun 15, support 16, fixture 17. In the picture, the first section of reinforcement cage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com