Road de-icing device and de-icing method suitable for loader

A technology for loaders and roads, which is applied in cleaning methods, snow surface cleaning, construction, etc. It can solve problems such as high cost, waste of manpower, and change in deicing efficiency. The effect of ensuring the quality of deicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

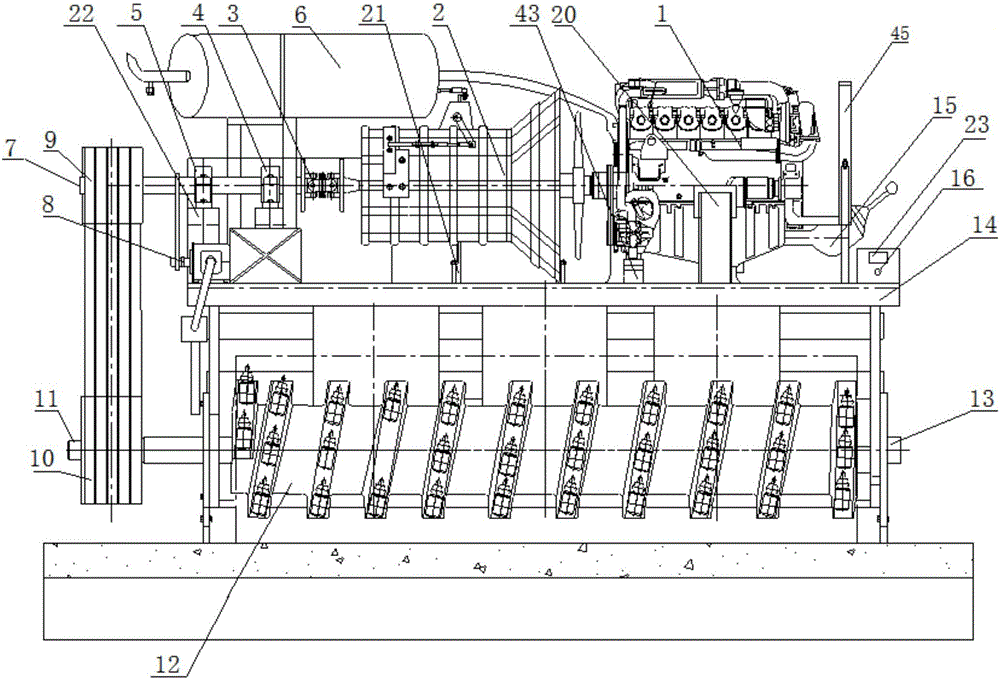

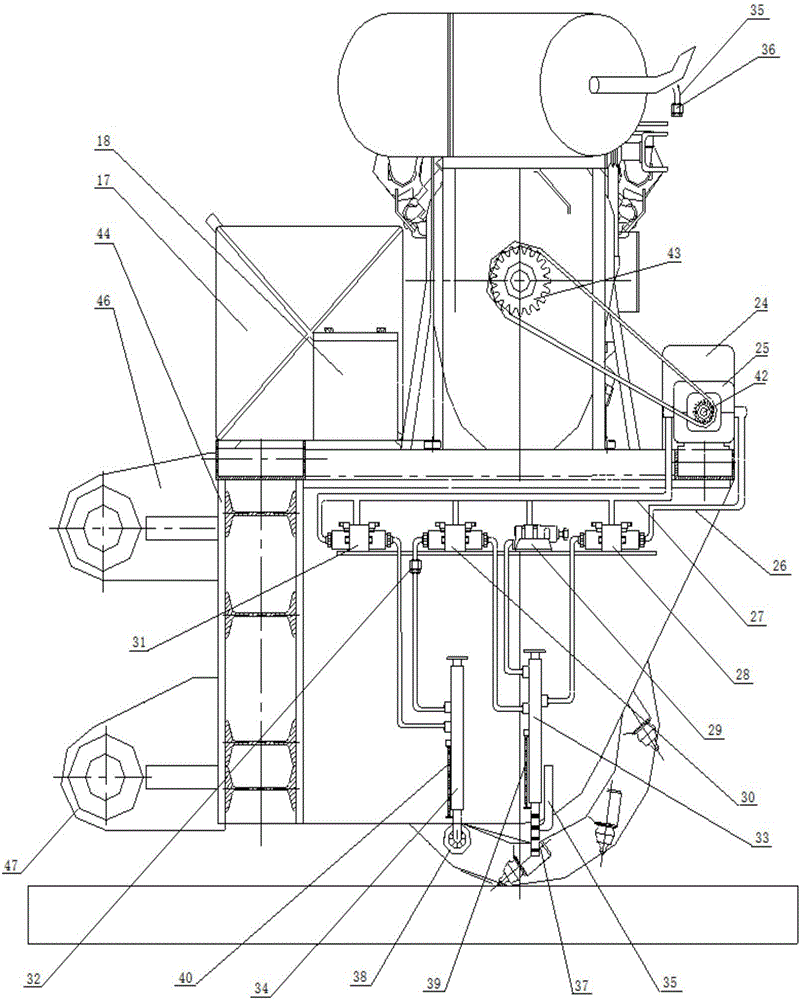

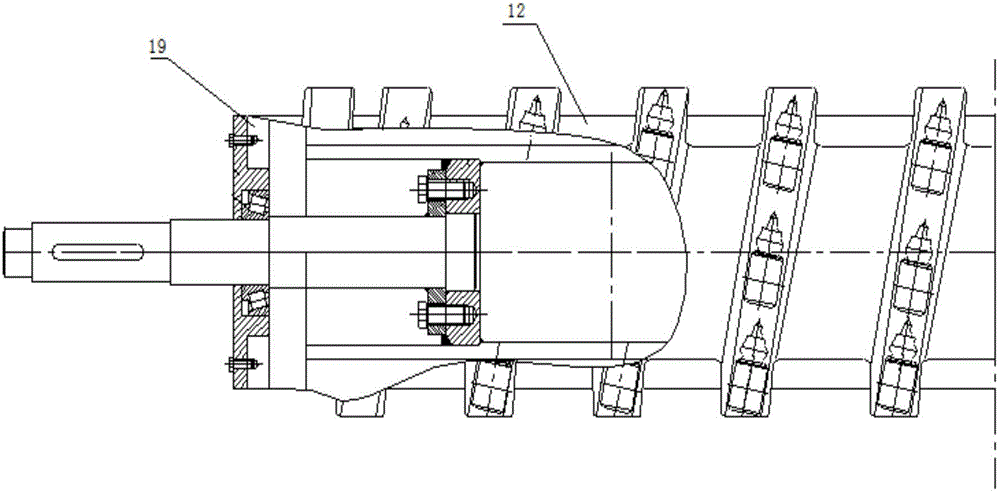

[0043] Such as figure 1 , Figure 5 As shown, a deicing mechanism suitable for a road deicing device of a loader in the present invention mainly includes: an engine 1, a gearbox 2, a universal joint 3, a tapered roller bearing 4, a tapered roller bearing seat 5, an output shaft 7. Small pulley I9, large pulley I10, left half shaft 11, milling drum 12, right half shaft 13, gearbox gear control device 15, stepper motor 16, fuel tank I17, battery box 18, water tank 45, Wherein the fuel tank I17, the battery box 18 and the water tank 45 which are matched with the engine 1 are arranged around the engine 1, and the ignition device of the engine 1 is arranged near the transmission gear control device 15. The oil outlet pipe of the fuel tank I17 is connected to the oil inlet pipe of the engine 1, the fuel tank I17 and the battery box 18 are respectively installed on the support buffer frame 14, and the battery box 18 is electrically connected to the stepping motor 16; the water tank ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com