Composite ultraviolet-proof coating, preparation method thereof and ultraviolet-proof glass

An anti-ultraviolet and coating technology, which is applied in the direction of radiation-absorbing coatings and coatings, can solve the problems of ineffective isolation and protection, and achieve the effect of effective isolation and protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

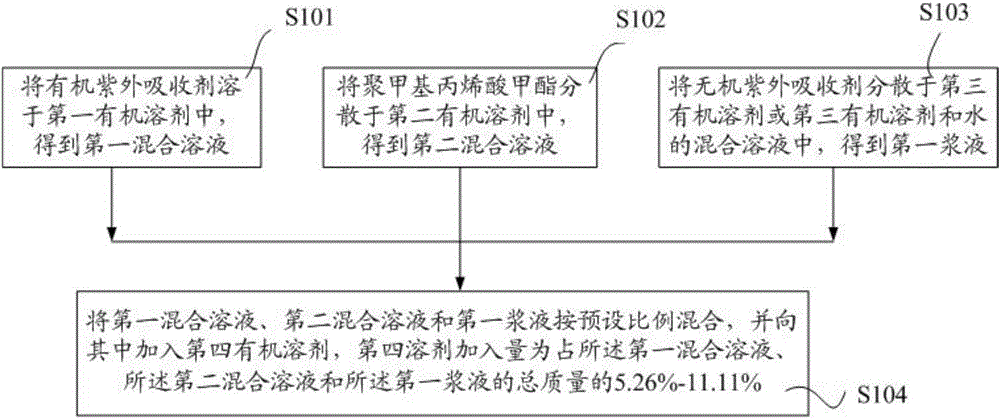

Method used

Image

Examples

Example Embodiment

[0049] As a preferred embodiment of the present invention, TiO in the inorganic ultraviolet absorber 2 with SiO 2 , ZnO, CeO 2 and ZrO 2 The weight ratio of at least one of them is 1-3:1. Inorganic ultraviolet absorbers within this ratio range can better cover the wavelength range of 290-400nm of ultraviolet rays, have better absorption effect on ultraviolet rays, and have higher transmittance of visible light.

[0050] In practical applications, it is preferred that the particle size of the inorganic UV absorber is 5-260nm, and the specific surface area is 86-140m 2 / g, more preferably the particle size of the inorganic UV absorber is 5-80nm, and the specific surface area is 86-140m 2 / g, the particle size of the inorganic ultraviolet absorber is too large to easily cause light scattering, and the specific surface area is 86-140m 2 / g of porous nano-powder can absorb organic UV absorbers, effectively reduce the loss of organic UV absorbers, and prolong the service life o...

Example Embodiment

[0085] Embodiment 1: This embodiment provides a method for preparing an anti-ultraviolet coating and an anti-ultraviolet glass, comprising the following steps:

[0086] (1) Dissolving the organic ultraviolet absorber 2-(2'-hydroxy-3',5'-di-tert-amylphenyl)benzotriazole in acetone to obtain the first mixed solution with a mass percentage content of 0.3% ;

[0087] The PMMA ultrafine powder with a particle diameter of 5.5 μm was dissolved with acetone to obtain a second mixed solution with a PMMA mass percentage content of 3%;

[0088] The particle size is 15-20nm, the pore size is 5-9nm, and the specific surface area is 140m 2 / g TiO 2 After mixing with the ZnO porous nano powder material according to the mass ratio of 1:1, add the ethanol / glycerol (volume ratio of 8:1) solution of the dispersant DisperBYK-190 and stir at a high speed to obtain the first slurry, wherein the stirring speed is 1200 rpm, stirring for 90 minutes, the content of the dispersant DisperBYK-190 is Ti...

Example Embodiment

[0091] Embodiment 2: This embodiment provides a method for preparing an anti-ultraviolet coating and an anti-ultraviolet glass, comprising the following steps:

[0092] (1) Dissolving the organic ultraviolet absorber 2-(2H-benzotriazol-2-yl)-4-methyl-6-(2-propenyl)phenol in ethanol to obtain 8% by mass percent the first mixed solution;

[0093] Dissolving PMMA ultrafine powder with a particle size of 6 μm in tetrahydrofuran to obtain a second mixed solution with a PMMA mass percentage content of 1%;

[0094] The particle size is 20-80nm, the pore size is 12-20nm, and the specific surface area is 100m 2 / g TiO 2 After mixing with the ZnO porous nano-powder material according to the mass ratio of 1:1, add it to the ethanol / glycerol (volume ratio of 9:1) solution containing the dispersant DisperBYK-160 and stir at a high speed to obtain the first slurry, wherein the stirring speed 1200 rpm, stirring for 100 minutes, the content of the dispersant DisperBYK-160 is TiO 2 and 2% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com