Waterborne polyurethane resin

A water-based polyurethane and resin technology, applied in textiles and papermaking, etc., can solve the problems of not being cold-resistant and unable to meet the requirements of low-temperature environment, and achieve the effects of improved performance, improved peel strength and water resistance, and excellent cold resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

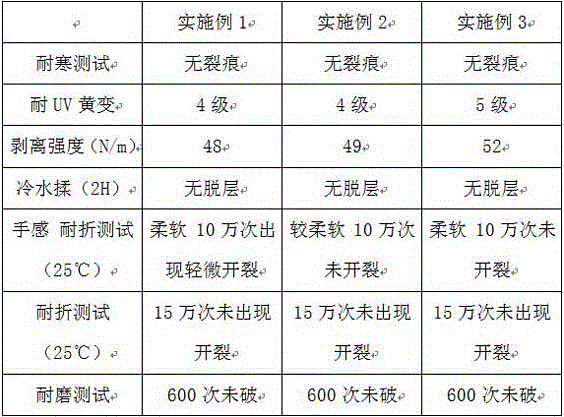

Embodiment 1

[0015] The water-based polyurethane resin of this embodiment, the water-based polyurethane resin includes the following raw material components and parts by weight: 20 parts of polyester polyol, 80 parts of tetrafluorofuran-propylene oxide copolyethylene glycol, 16 parts of isophorone diisocyanate, chain extension 10 parts of agent, 5 parts of salt-forming agent, 2 parts of organic bismuth catalyst and 400 parts of water; among them, polyester polyol is formed by mixing polycaprolactone polyol and polycarbonate polyol, polycaprolactone polyol 12.6 parts, polycarbonate polyol 7.4 parts; the chain extender is a mixture of ethylene glycol and isophorone diamine, 4 parts of ethylene glycol, 6 parts of isophorone diamine; the salt forming agent is three A mixture of ethylamine and acetic acid, 2.83 parts of triethylamine, 2.17 parts of acetic acid.

Embodiment 2

[0017] The water-based polyurethane resin of this embodiment, the water-based polyurethane resin includes the following raw material components and parts by weight: 20 parts of polyester polyol, 80 parts of tetrafluorofuran-propylene oxide copolyethylene glycol, 16 parts of isophorone diisocyanate, chain extension 10 parts of agent, 5 parts of salt-forming agent, 2 parts of organic bismuth catalyst and 400 parts of water; among them, polyester polyol is formed by mixing polycaprolactone polyol and polycarbonate polyol, polycaprolactone polyol 13.55 parts, 6.45 parts of polycarbonate polyol; the chain extender is a mixture of ethylene glycol and isophorone diamine, 3.33 parts of ethylene glycol, 6.67 parts of isophorone diamine; the salt forming agent is three A mixture of ethylamine and acetic acid, 3.15 parts of triethylamine, 1.85 parts of acetic acid.

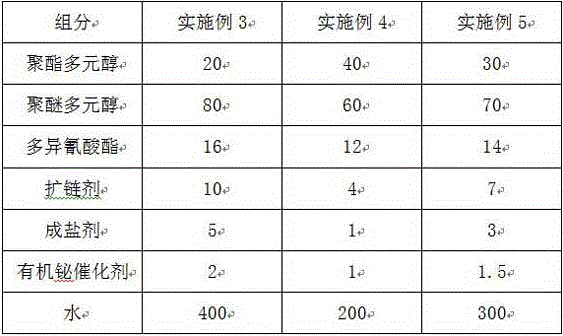

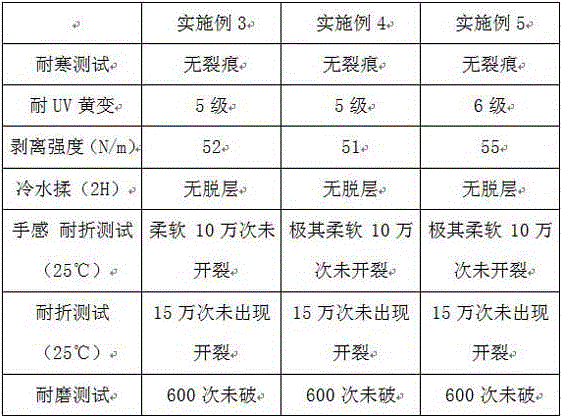

Embodiment 3

[0019] The water-based polyurethane resin of this embodiment, the water-based polyurethane resin includes the following raw material components and parts by weight: 20 parts of polyester polyol, 80 parts of tetrafluorofuran-propylene oxide copolyethylene glycol, 16 parts of isophorone diisocyanate, chain extension 10 parts of agent, 5 parts of salt-forming agent, 2 parts of organic bismuth catalyst and 400 parts of water; among them, polyester polyol is formed by mixing polycaprolactone polyol and polycarbonate polyol, polycaprolactone polyol 13.1 parts, 6.9 parts of polycarbonate polyol; the chain extender is a mixture of ethylene glycol and isophorone diamine, 3.64 parts of ethylene glycol, 6.36 parts of isophorone diamine; the salt forming agent is three A mixture of ethylamine and acetic acid, 3 parts of triethylamine, 2 parts of acetic acid.

[0020] The following table 1 is polycaprolactone polyol and polycarbonate polyol in polyester polyol in embodiment 1-3, ethylene g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com