Preparation method and application of grafted starch

A technology of grafting starch and starch, which is applied in the biological field, can solve the problems of low grafting rate and grafting efficiency, and achieve the effects of small environmental pollution, large-scale production, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

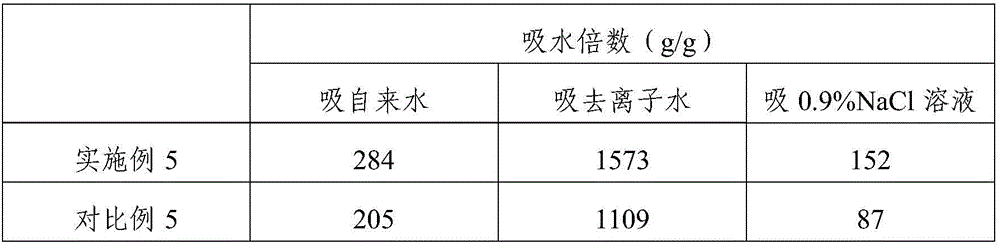

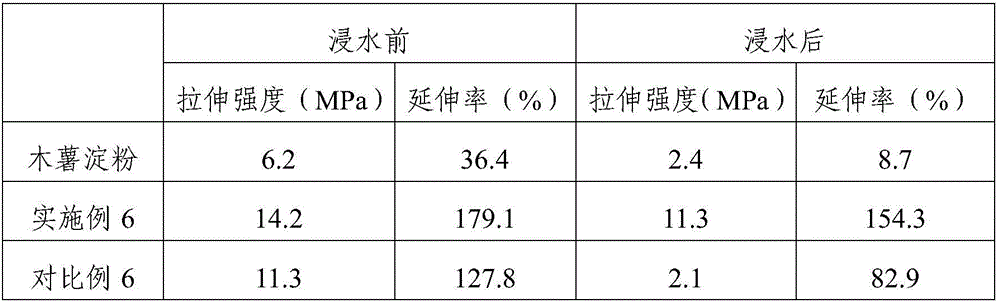

Examples

Embodiment 1

[0042] A preparation method of grafted corn starch includes the following steps:

[0043] (1) Weigh 2kg of corn starch and disperse it in 18L methanol-water solution (the volume ratio of methanol to water is 10:90) to prepare a corn starch emulsion suspension with a concentration of 10.19%, and put it into an electrolytic cell with a volume of 24L In, weigh 255.6g of sodium sulfate (0.1mol / L) and dissolve it in the corn starch emulsion suspension, and adjust the pH of the corn starch emulsion suspension to 3 with 1 mol / L sulfuric acid. Take 30cm×30cm wire mesh as anode, 30cm×30cm porous graphite as cathode, the distance between the two poles is 5cm, and 14V direct current is applied (cathode current density is 14mA / cm 2 ), and use an aeration device to blow in oxygen at a speed of 0.7L / min (the aeration device contains two vents, and the two vents blow in oxygen at the same time), and the amount of oxygen per liter of corn starch emulsion suspension is about 4.67L, the agitator s...

Embodiment 2

[0047] A preparation method of grafted potato starch includes the following steps:

[0048] (1) Weigh 3kg of potato starch and disperse it in 17L of ethanol-water solution (the volume ratio of ethanol to water is 15:85) to make a potato starch emulsion suspension with a concentration of 15.42%, and put it into an electrolytic cell with a volume of 24L Weigh 193.12g sodium sulfate (0.08mol / L) and dissolve it in the potato starch emulsion suspension, and adjust the pH to 3 with 1mol / L nitric acid. Take 30cm×30cm wire mesh as anode, 30cm×30cm porous graphite as cathode, the distance between the two poles is 6cm, and 12V direct current is applied (cathode current density is 12mA / cm 2 ), and use an aeration device to inject oxygen at a rate of 0.6L / min (the aeration device contains three vent holes, and the three vent holes simultaneously blow oxygen), and the amount of oxygen introduced per liter of starch solution is about 5.29L, The stirrer stirs at a speed of 250 rpm, and reacts f...

Embodiment 3

[0052] A preparation method of grafted tapioca starch includes the following steps:

[0053] (1) Weigh 4kg of tapioca starch and disperse it in 16L methanol-water solution (the volume ratio of methanol to water is 20:80) to prepare a tapioca starch emulsion suspension with a concentration of 20.69% and fill it into an electrolytic cell with a volume of 24L 272.64g sodium sulfate (0.12mol / L) was weighed and dissolved in the tapioca starch milk suspension, and the pH was adjusted to 3 with 1mol / L sulfuric acid. With 30cm×30cm iron wire as anode, 30cm×30cm porous graphite as cathode, the distance between the two electrodes is 5cm, and 13V direct current is applied (the cathode current density is 13mA / cm 2 ) And use the aeration device to inject oxygen at a rate of 0.5L / min (the aeration device contains three vent holes, and the three vent holes simultaneously blow oxygen), the amount of oxygen introduced per liter of starch solution is about 3.75L, stir Stirring at 250 rpm and react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com