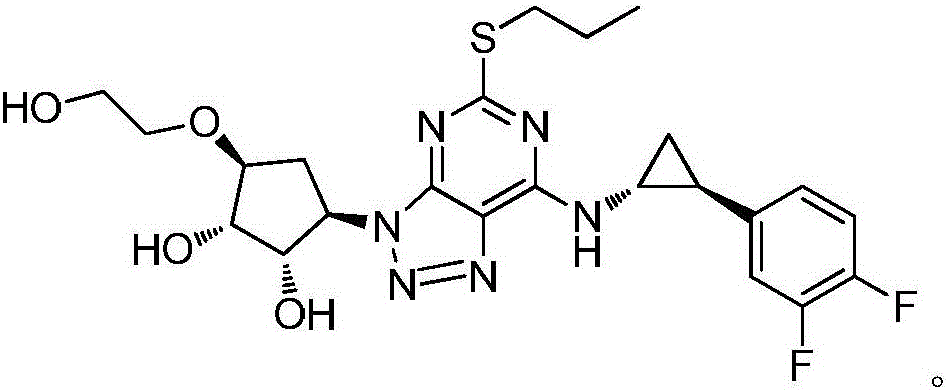

Preparation method for ticagrelor intermediate

A technology for ticagrelor and intermediates, which is applied in the field of preparation of ticagrelor intermediates, can solve the problems of difficult purification of products and low yield of sulfur-alkylation, and achieve easy purification of products, few by-products, The effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

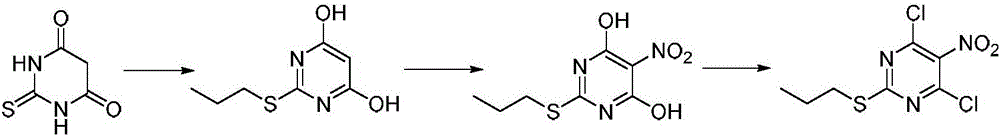

Method used

Image

Examples

Embodiment 1

[0033] In a 500ml flask, add 200ml 30% acetic acid aqueous solution, then add 41g (200mmol) of 2-nitro-1,3-diethyl malonate, 19.5g (240mmol) of sodium thiocyanate and 24.8g (400mmol) of ammonium acetate ) into the flask, kept stirring at 25°C for 5 hours, TLC monitored the completion of the reaction, poured the reaction solution into ice water, adjusted the pH to 8 with sodium bicarbonate, filtered, washed the filter cake with water three times, and dried in vacuo to obtain the compound shown in formula II 45.7g, yield 97.1%.

Embodiment 2

[0035]In the 500ml flask, add 200ml 20% acetic acid aqueous solution, then 2-nitro-1,3-diethyl malonate 41.0g (200mmol), sodium thiocyanate 19.5g (240mmol) and ammonium acetate 22.4g ( 360mmol) was added in the flask, kept stirring at 20°C for 5 hours, TLC monitored the completion of the reaction, poured the reaction solution into ice water, adjusted the pH to 8 with sodium bicarbonate, filtered, washed the filter cake with water three times, and dried in vacuo to obtain the compound shown in formula II Compound 46.0g, yield 97.7%.

Embodiment 3

[0037] In a 500ml flask, add 220ml 30% acetic acid aqueous solution, then add 41g (200mmol) of 2-nitro-1,3-diethyl malonate, 22.7g (280mmol) of sodium thiocyanate and 18.6g (300mmol) of ammonium acetate ) into the flask, heat up and keep stirring at 40°C for 4.5 hours, TLC monitors the completion of the reaction, pours the reaction solution into ice water, adjusts the pH to 8 with sodium bicarbonate, filters, washes the filter cake with water three times, and vacuum-dries to obtain formula II Compound 45.7g, yield 97.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com