Production device and production method of phosphorus oxychloride

A technology for phosphorus oxychloride and production equipment, applied in the direction of phosphorus halide/oxyhalide, etc., can solve the problems of low oxygen utilization rate, low production efficiency, complicated production process, etc., and achieves superior effect, high production safety, Reasonable effect of temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

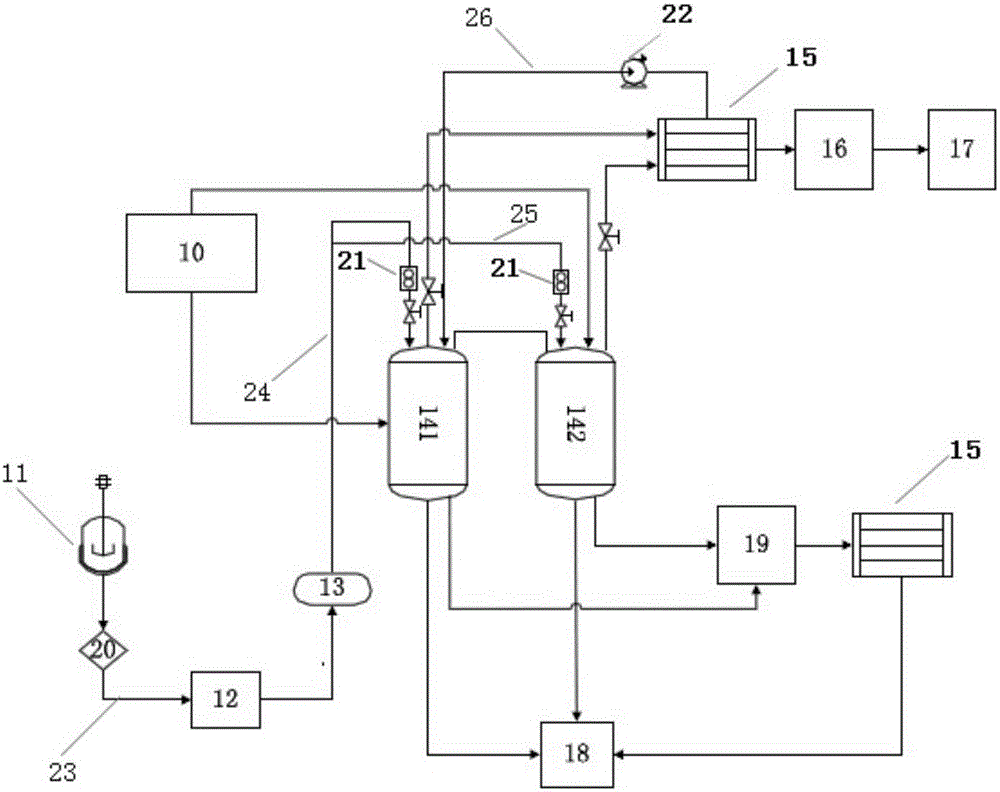

[0039] A production device for phosphorus oxychloride, comprising a liquid oxygen storage tank 11, a vaporizer 12, a buffer tank 13, a phosphorus trichloride header tank 10, a first reaction kettle 141, a second reaction kettle 142, a condenser 15, and a finished product storage Tank 18, tail gas absorption tower 16 and waste water treatment tank 17.

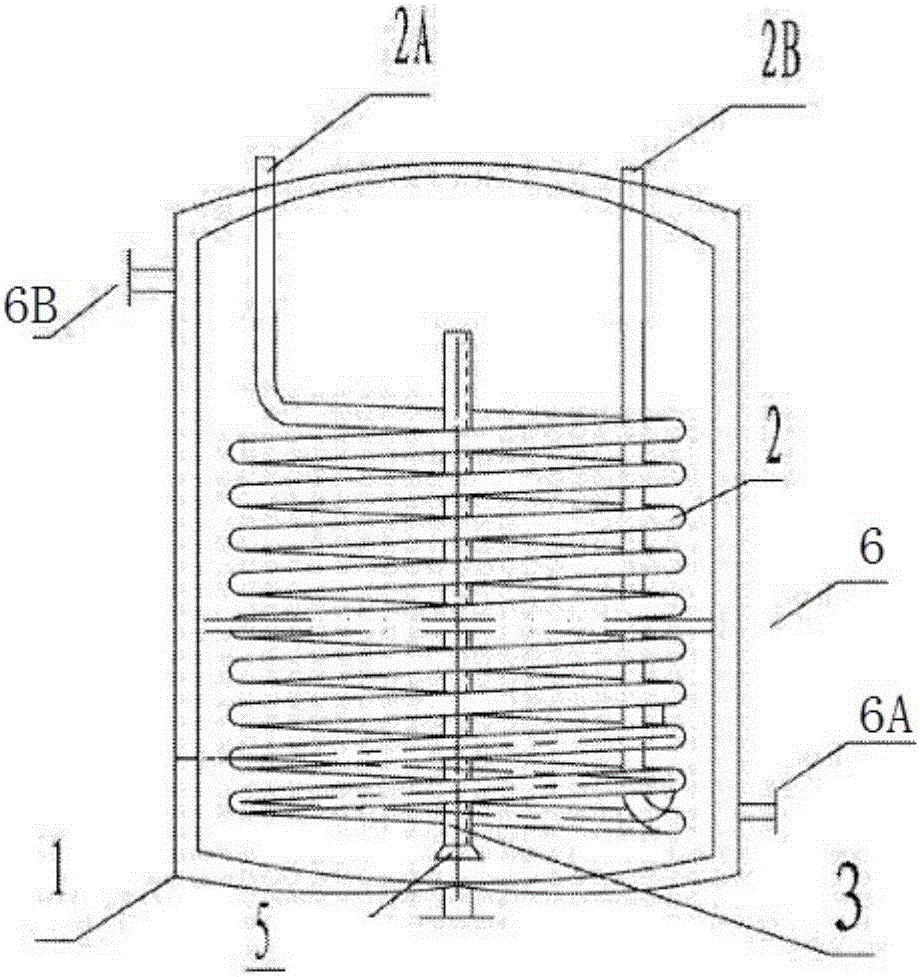

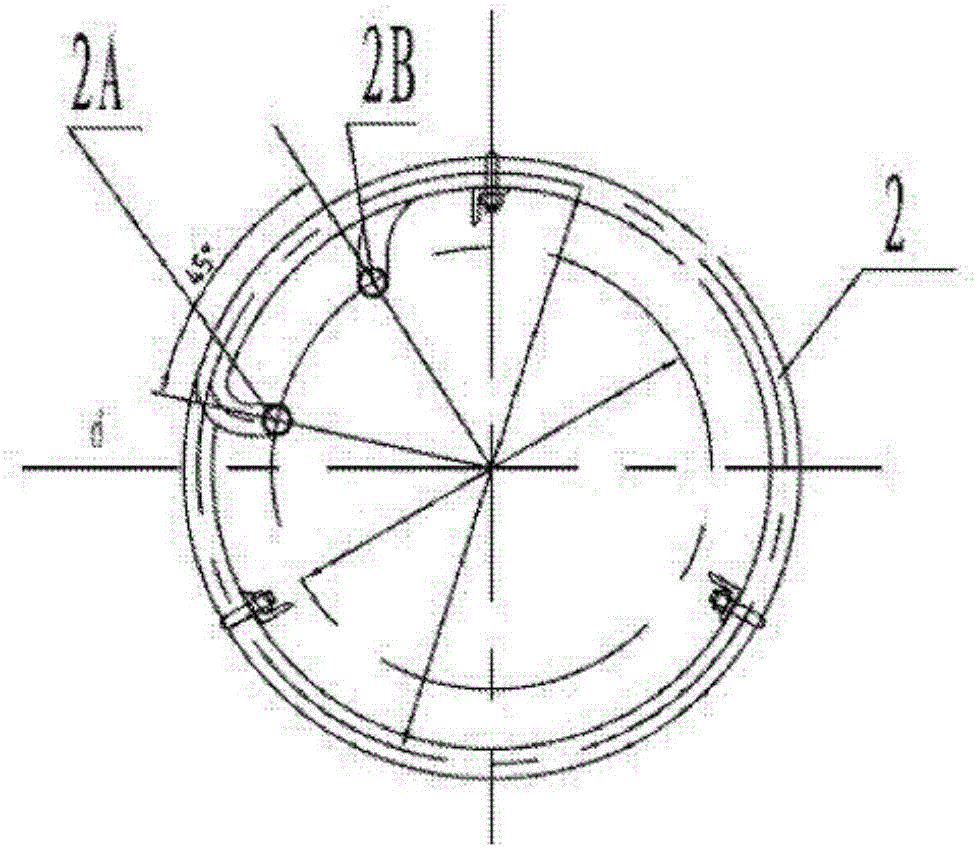

[0040] Such as figure 1 As shown, the liquid oxygen storage tank 11 is connected to the vaporizer 12 through a first pipeline, and a voltage stabilizer 20 is arranged on the first pipeline. The second pipeline and the third pipeline are connected with the first reactor 141 and the second reactor 142, and the second pipeline and the third pipeline are equipped with an oxygen flowmeter 21 and a control valve; the first reactor 141 and the second reactor 142 is provided with the water inlet 6A and the water outlet 6B of material inlet, finished product outlet and jacket; The fourth pipeline is connected with the material inlet of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com