Method for manufacturing low-nicotine reconstituted tobacco leaves by taking Maryland tobaccos as raw materials

A technology for reconstituted tobacco leaves and raw materials, which is applied in the fields of tobacco, tobacco preparation, and application, can solve the problems of insufficient aroma, loss of tobacco aroma of reconstituted tobacco leaves, and weakened taste, so as to achieve complete coverage, improve production applicability, and reduce irritation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

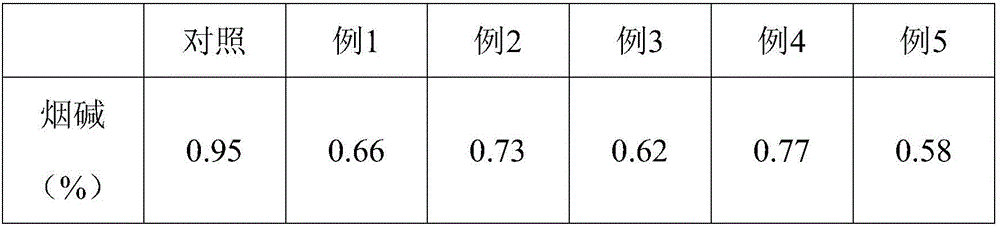

Examples

Embodiment Construction

[0023] The specific implementation of the present invention will be further described in detail below in conjunction with the examples.

[0024] A method for manufacturing low-nicotine reconstituted tobacco leaves using Maryland tobacco as a raw material. The reconstituted tobacco leaves are made by papermaking after extracting the tobacco leaves, tobacco leaf fragments, tobacco powder and tobacco stems of Maryland tobacco respectively; The first embodiment is tested to it, and the steps of five embodiments are identical, and all comprise the following steps:

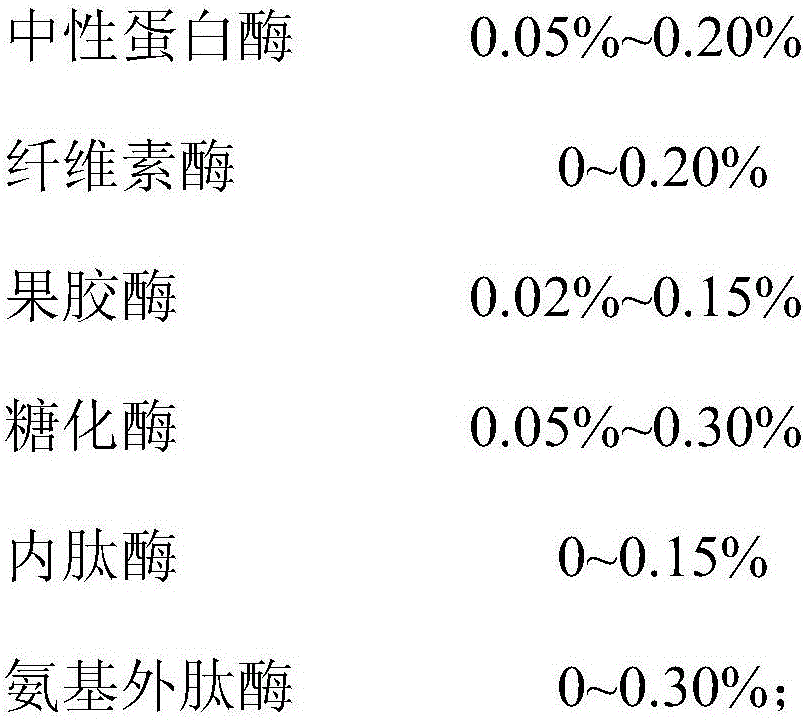

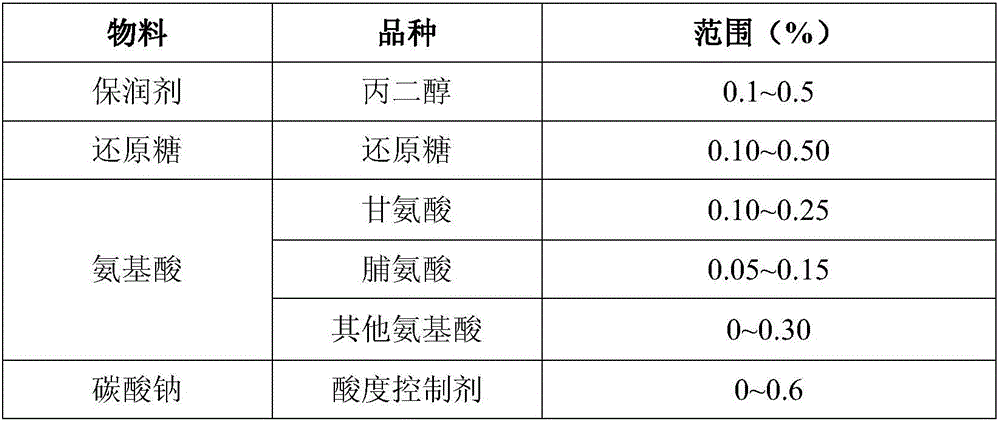

[0025] (1) Add Maryland tobacco leaf fragments or tobacco powder and water into the raw material extraction tank according to the ratio of material to liquid ratio of 1:4.5, control the temperature at 65-75°C, soak for 5-10 minutes, and then cool it naturally to 45 ± 5 ° C, then add the compound enzyme preparation to extract for 20 to 50 minutes. The percentage of each enzyme in the compound enzyme preparation described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com