Tobacco leaf processing device and processing method

A processing device and processing method technology, applied in the direction of tobacco, tobacco preparation, application, etc., can solve the problems of affecting usability, high proportion of miscellaneous smoke, insufficient maturity of upper tobacco leaves, etc., and achieve the effect of improving the use effect and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

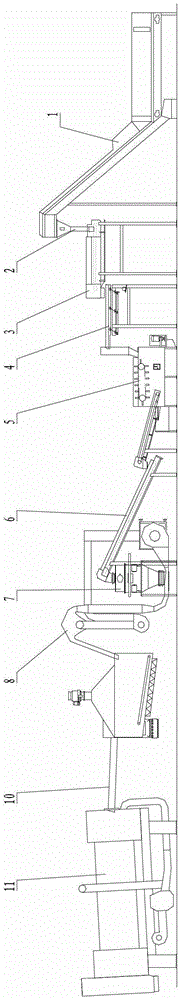

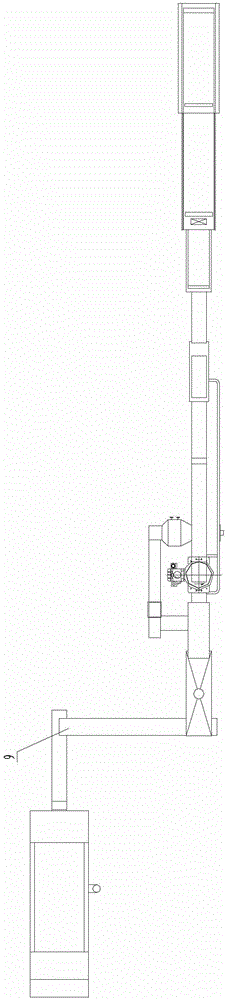

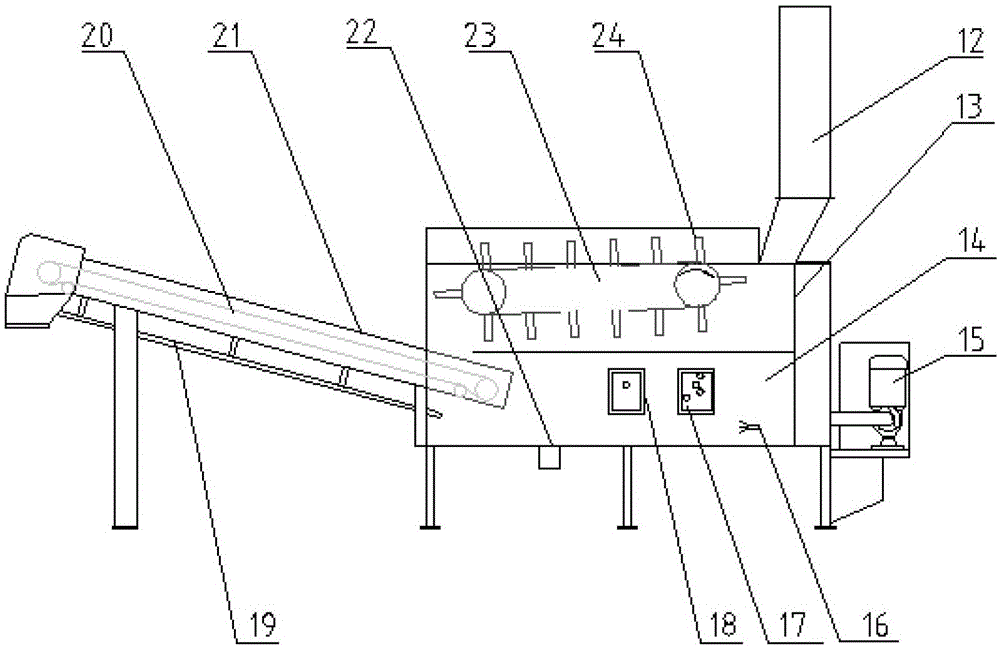

[0075] Such as figure 1 , figure 2 As shown, the processing device for tobacco leaves of the present invention includes a quantitative feeding system, a vibrating conveyor 4, a tobacco leaf soaking machine 5, a belt conveyor 6, a tobacco leaf centrifugal dryer 7, a tobacco leaf primary dryer 8, and a tobacco leaf secondary dryer 11;

[0076] The quantitative feeding system includes a feeder 1, a limit tube 2, and an electronic scale 3. The output of the feeder 1 is connected to the inlet of the limit tube 2, and the outlet of the limit tube 2 is connected to the inlet of the electronic scale 3; the outlet of the electronic scale 3 is connected to the The entrance of the vibrating conveyor 4; the quantitative feeding system can keep the tobacco leaves at a stable flow rate to ensure the treatment quality of the tobacco leaves;

[0077] The outlet of the vibrating conveyor 4 is connected to the feed cover of the tobacco leaf soaking machine 5, the discharge end of the tobacco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com