Aromatic tobacco additive and processing method and application of aromatic tobacco

A processing method and technology for oriental tobacco, which are applied in the application, tobacco, preparation of tobacco and other directions, can solve the problem that the application of oriental tobacco has not been reported in literature, etc., and achieve the effects of improving aroma quality, harmonizing tobacco aroma, and improving aftertaste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

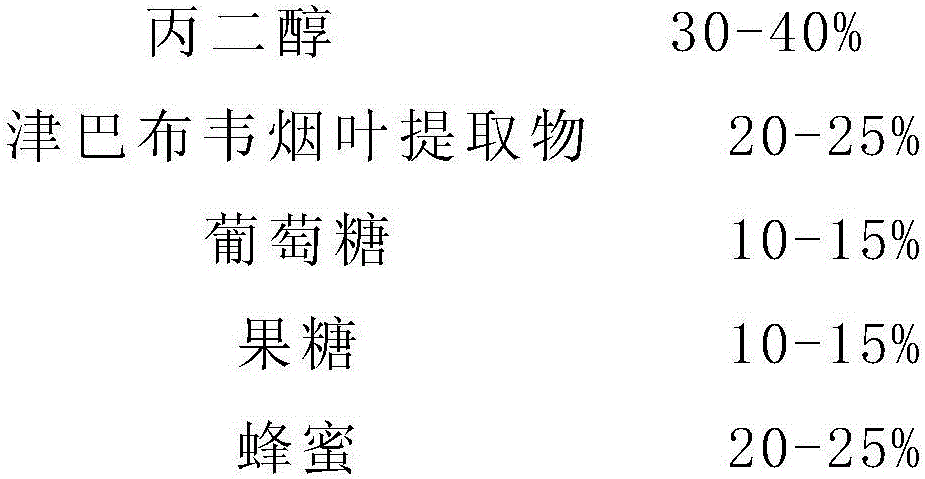

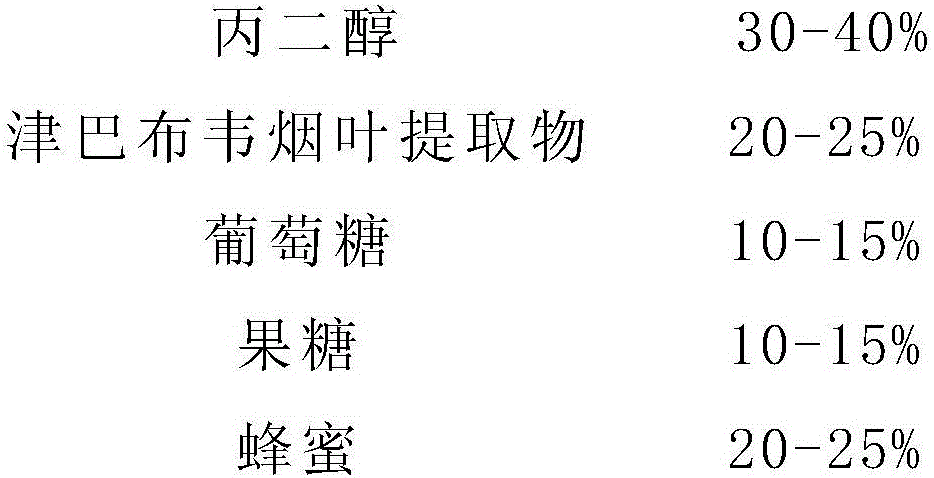

Embodiment 1

[0014] Example 1, a treatment method for oriental tobacco, the specific steps are as follows: take the oriental tobacco after threshing and rebaking, add cigarette additives according to 1.5% of the weight of the oriental tobacco, and bake at 65°C for 35 minutes to obtain the oriental tobacco prepared by the present invention. oriental tobacco. The cigarette additive is prepared from propylene glycol, Zimbabwean extract, glucose, fructose and honey in a weight ratio of 3:2:1:1:2.

[0015] The shredded oriental tobacco treated in Example 1 was added to the shredded flue-cured tobacco according to 5% of the weight of the total shredded flue-cured tobacco, mixed evenly, and rolled into cigarettes.

Embodiment 2

[0016] Example 2, a treatment method for oriental tobacco, the specific steps are as follows: take the oriental tobacco after threshing and rebaking, add cigarette additives according to 1.8% of the weight of the oriental tobacco, and bake at 65°C for 35 minutes to obtain the oriental tobacco prepared by the present invention oriental tobacco. The cigarette additive is prepared from propylene glycol, Zimbabwean extract, glucose, fructose and honey in a weight ratio of 3:2:1:1:2.

[0017] The shredded oriental tobacco treated in Example 2 was added to the shredded flue-cured tobacco according to the weight of 7.5% of the total shredded flue-cured tobacco, mixed evenly, and rolled into cigarettes.

Embodiment 3

[0018] Embodiment 3, a kind of processing method of oriental tobacco, concrete steps are as follows:

[0019] Take the threshed and rebaked oriental tobacco, add cigarette additives according to 2.0% of the weight of the oriental tobacco, and bake at 65° C. for 40 minutes to obtain the oriental tobacco prepared in the present invention. The cigarette additive is prepared from propylene glycol, Zimbabwean extract, glucose, fructose and honey in a weight ratio of 3:2:1:1:2.

[0020] The shredded oriental tobacco treated in Example 3 was added to the shredded flue-cured tobacco according to 10% of the weight of the total shredded flue-cured tobacco, mixed evenly, and rolled into cigarettes.

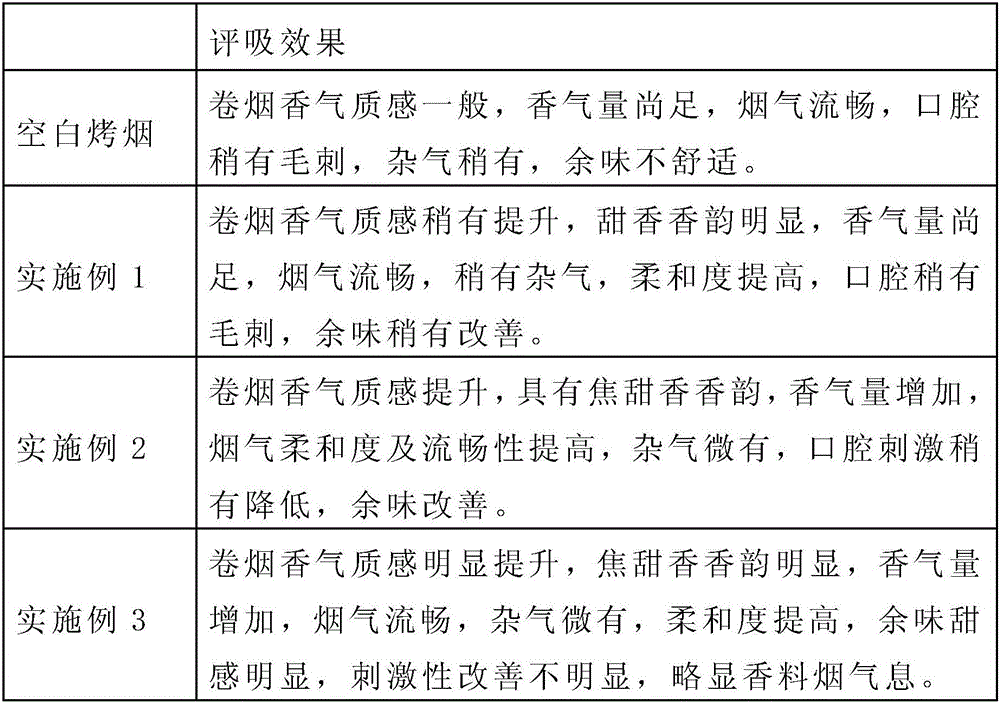

[0021] The cigarettes prepared in the above three examples and the blank cigarettes were smoked by a professional smoking evaluation team, and the specific smoking evaluation results are shown in Table 1:

[0022] Table 1 Adding the flue-cured tobacco of the present invention to evaluate sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com