Production method of an instantly edible recreational fish snack

A production method and technology of fish fillets, which are applied in the direction of food science, etc., can solve the problems of rough taste and poor flavor of ready-to-eat fish fillets, and achieve the effects of mellow flavor, preventing surface hardening, and increasing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The production technology of embodiment 1. instant leisure catfish:

[0032] 1. Raw material pretreatment Remove the heads, scales, and viscera of fresh or chilled catfish, rinse them with clean water, and drain the water. Adopt the chlorine dioxide of 20ppm to carry out spray disinfection to fish, and spray amount is 2% of fish weight. After the meat is harvested and frozen, the fish meat is cut into thin slices of 4mm.

[0033] 2. Deodorization: Soak the pretreated fish fillets in the deodorization solution for 3 hours at a temperature of 4°C, and then rinse with running water. The composition of the compound deodorizing agent in the deodorizing liquid is as follows: ginger powder 1.5% g / L, black tea 1% g / L, perilla 2% g / L, and table salt 1% g / L.

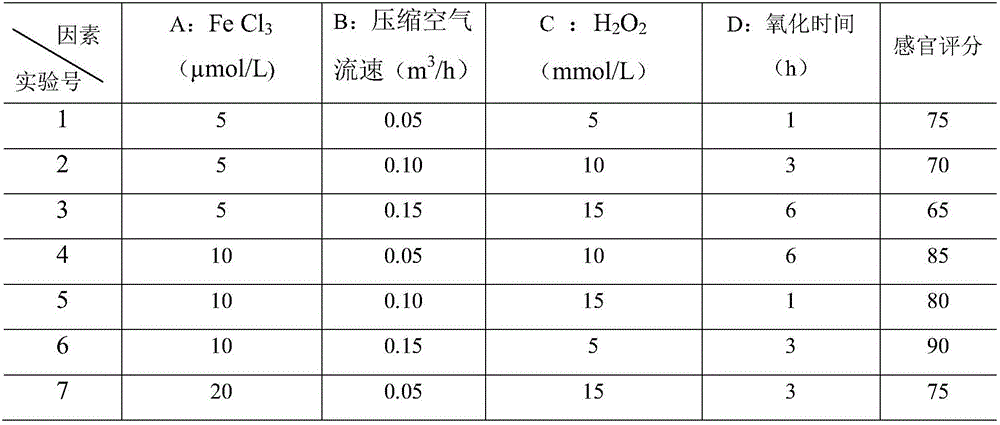

[0034] 3. Regulation and oxidation of fish fat Put the deodorized fish fillets into the solution containing oxidant to oxidize for 1 hour, the temperature is 4°C, and the compressed air flow rate in the tank is 0.15m 3 / ...

Embodiment 2

[0043] The production technology of embodiment 2. instant leisure white fish:

[0044] 1. Raw material pretreatment Remove the scales and viscera of fresh or chilled white fish, rinse with clean water, and drain the water. Adopt 5ppm chlorine dioxide to carry out spray disinfection to fish, spray amount is 1% of fish weight. After the meat is harvested and frozen, the fish meat is cut into 3mm slices.

[0045] 2. Deodorization Put the pretreated fish fillets into the deodorization liquid and soak for 1 hour at a temperature of 4°C, then rinse with flowing water. The composition of the compound deodorizing agent in the deodorizing liquid is as follows: ginger powder 1.5% g / L, black tea 1% g / L, perilla 2% g / L, and table salt 1% g / L.

[0046] 3. Adjustment and oxidation of fish fat Put the deodorized fish fillets into the solution containing oxidant to oxidize for 2 hours, the temperature is 10°C, and the compressed air flow rate in the tank is 0.05m 3 / h. The oxidation react...

Embodiment 3

[0054] Embodiment 3. the production technology of instant leisure silver carp:

[0055] 1. Raw material pretreatment Remove the heads, scales, and viscera of fresh or chilled silver carp, rinse them with clean water, and drain the water. Adopt the chlorine dioxide of 20ppm to carry out spray disinfection to fish, and spray amount is 1% of fish weight. After the meat is harvested and frozen, the fish meat is cut into 6mm slices.

[0056] 2. Deodorization Put the pretreated fish fillets into the deodorization liquid and soak for 1 hour at a water temperature of 10°C, then rinse with running water. The composition of the compound deodorizing agent in the deodorizing liquid is as follows: ginger powder 1.5% g / L, black tea 1% g / L, perilla 2% g / L, salt 1% g / L, and the weight of the deodorizing liquid is 4% of the weight of the fish. times.

[0057] 3. Regulation and oxidation of fish fat Put the deodorized fish fillets into a solution containing an oxidizing agent to oxidize for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com