Processing technology for making black tea by persimmon large-scale tea improved varieties

A processing technology and technology for large persimmon tea, which is applied in the field of processing technology for making black tea from improved varieties of large persimmon tea, can solve the problems of difficult to control product specifications, different sizes, and difficult to further improve product quality, and achieve the effect of good processing effect and stable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Select the fine persimmon tea varieties with 1 bud and 2 leaves that are just unfolding for picking. The picked buds and leaves are shipped in clean, well-ventilated tea baskets or bamboo baskets to maintain the freshness and integrity of the fresh leaves. Since the water content and content of different fresh leaves are different, fresh leaves picked at different times of the day and buds and leaves with different tenderness should be processed separately to avoid uneven fermentation and ensure the quality of tea.

[0050] Adopt the method of withering in sunlight facilities, set up a facility withering field with a controllable shading rate, spread the fresh leaves evenly on nylon cloth, bamboo mats or water screens, the thickness of the spread leaves is 2.5cm, adjust the shading rate to reduce the temperature of the leaf surface Control the temperature below 32°C and not lower than 28°C, and stir once every 15 minutes. End withering after 40 minutes. At this time, th...

Embodiment 2

[0057] Pick the fine varieties of persimmon tea with 1 bud and 2 leaves, and use the withering tank to wither. Spread the fresh leaves evenly according to the thickness of 16 cm. Stir once every 1 hour, and stop blowing when stirring. End withering after 4 hours. At this time, the water content of the withered leaves is about 62%. If the degree of withering is insufficient, the withering time can be extended to 5 hours, so as to prevent the tea leaves from being broken during rolling due to the high quality of the leaves, which will affect the quality of the tea.

[0058] Utilize the pressure kneading machine to knead the tea leaves, first put tea leaves in the feeding chamber 23, the push rod 34 pushes the left hemispherical shell 25 to move to the right and closes with the right hemispherical shell 26 to form a kneading ball 22. Drive the second motor 33 to drive the kneading ball 22 to rotate, and the second kneading bar 28 and the second kneading bar 30 in the kneading bal...

Embodiment 3

[0064] Pick the fine varieties of persimmon tea with 1 bud and 2 leaves, and use the withering tank to wither. Spread the fresh leaves evenly according to the thickness of 15 cm. Stir once every 1 hour, and stop blowing when stirring. End withering after 4.5 hours. At this time, the water content of the withered leaves is about 62%. If the degree of withering is insufficient, the withering time can be extended to 5 hours, so as to prevent the tea leaves from being broken during rolling due to the high quality of the leaves, which will affect the quality of the tea.

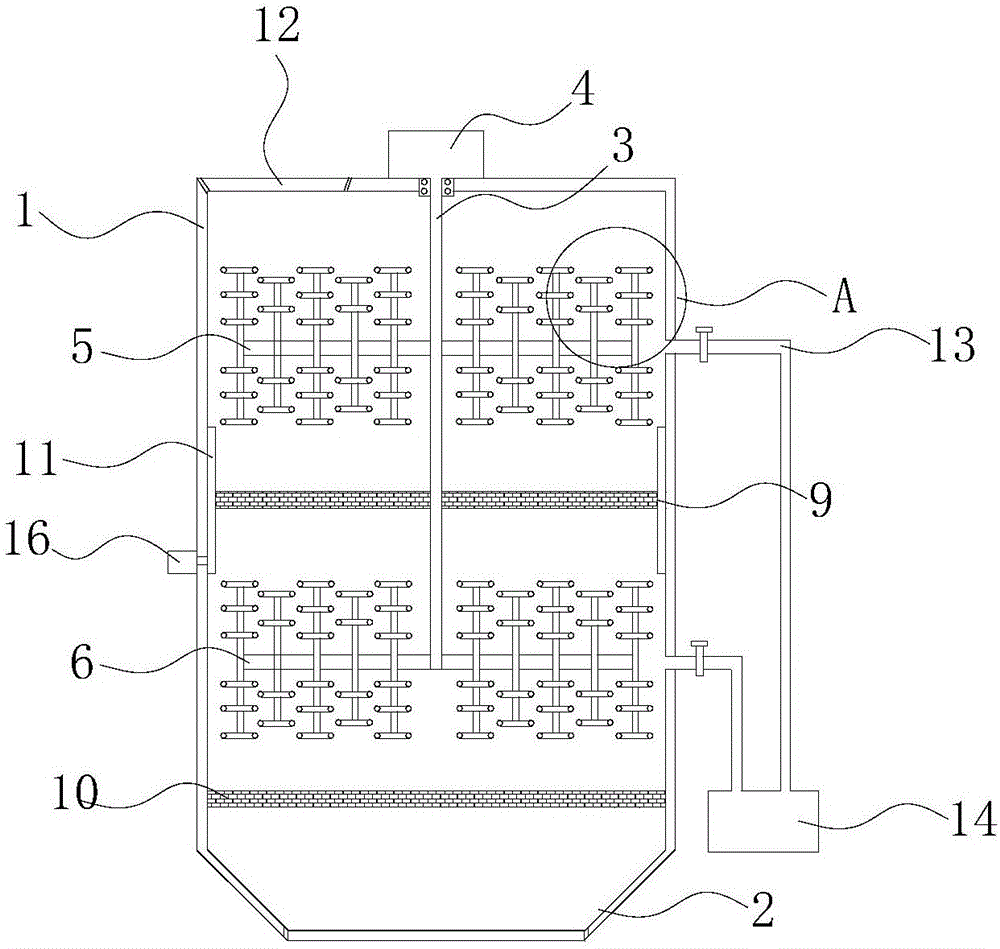

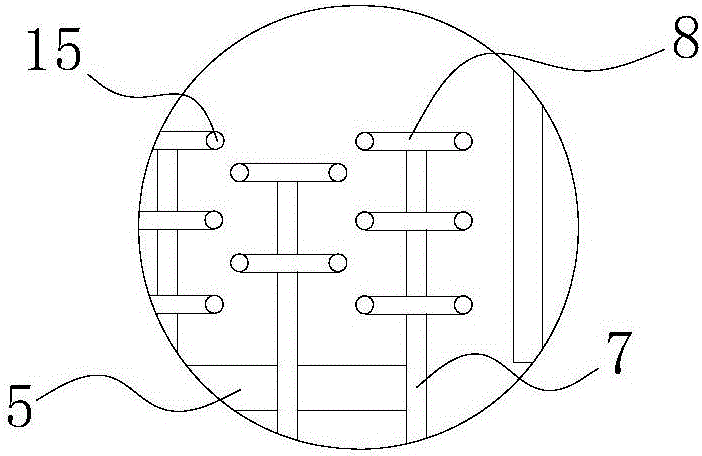

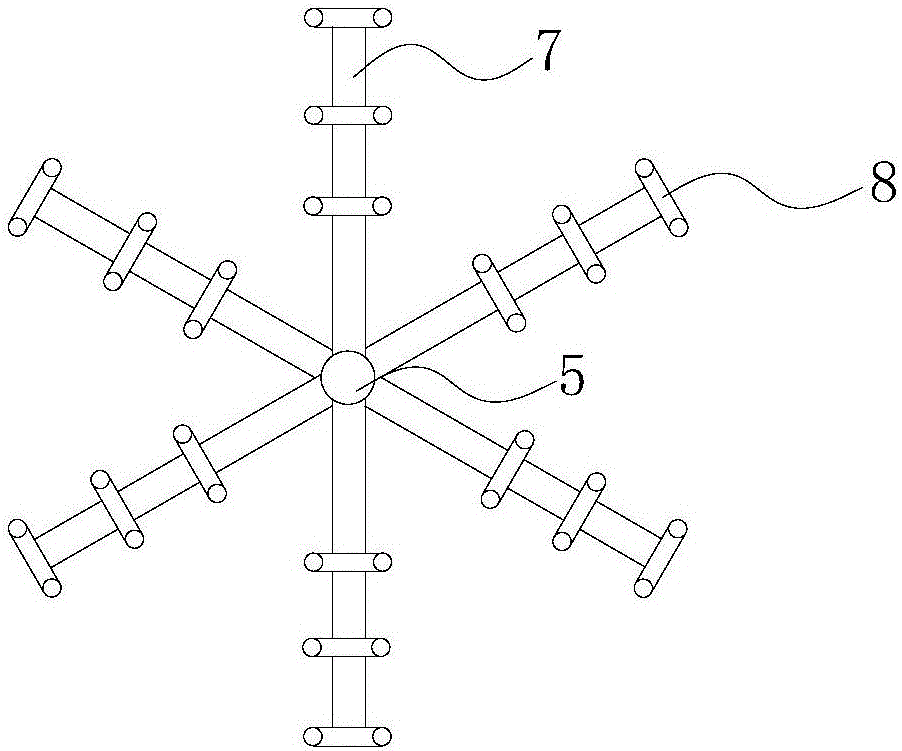

[0065] Use the sub-sieve rolling machine to knead the tea leaves, first close the first sieve plate 9 and raise it to the highest point, then open the feeding door to put in the tea leaves, drive the reduction motor 4 to knead for 27 minutes under normal pressure, and then open the connection to the first kneading Keep the valve and air compressor 14 on the pipeline 13 of the room, knead for 11 minutes under light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com