Energy-saving and environment-friendly gas heating and water heating boiler

A gas-fired heating and hot water boiler technology, applied in the field of heating and hot water boilers, can solve the problems of increasing the heating area, low heat utilization rate, and high heat exchange efficiency, and achieve increased heating area, large heat exchange capacity, and high heat exchange efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

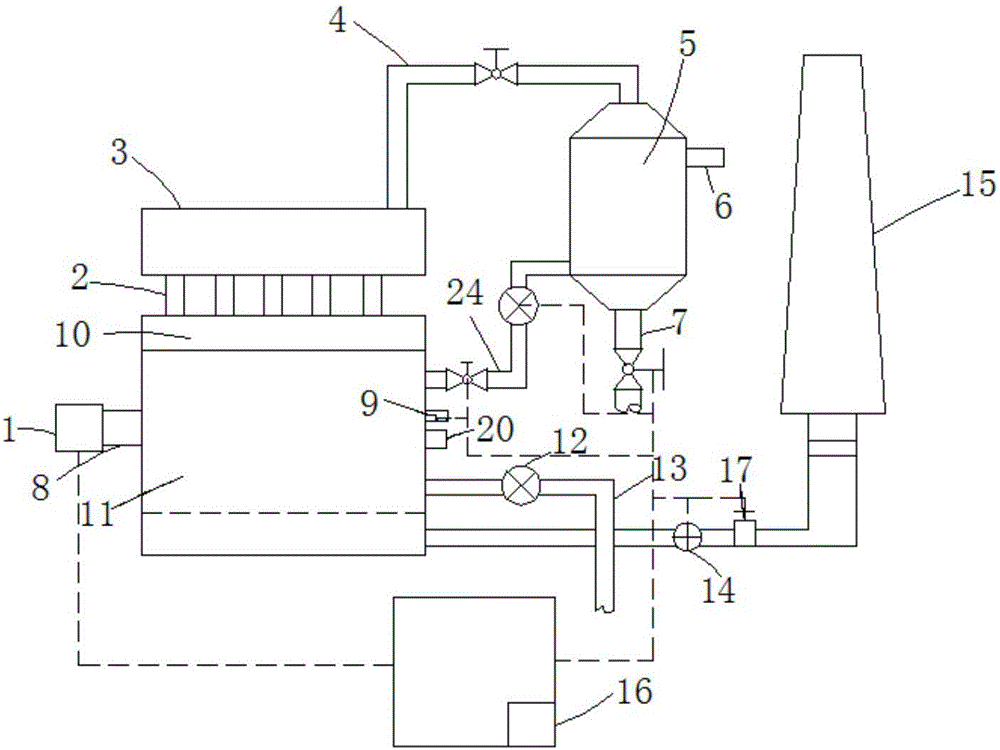

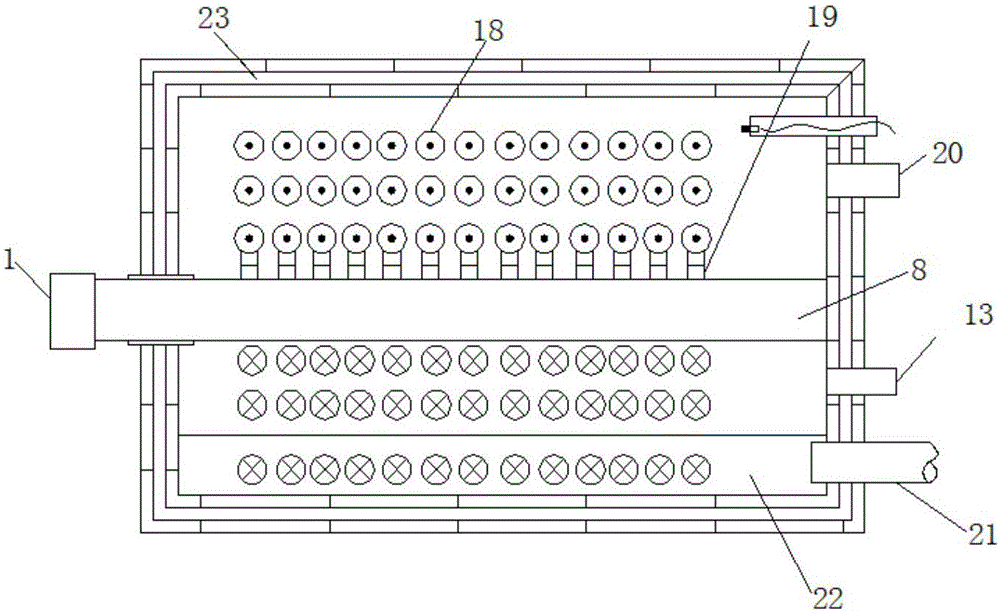

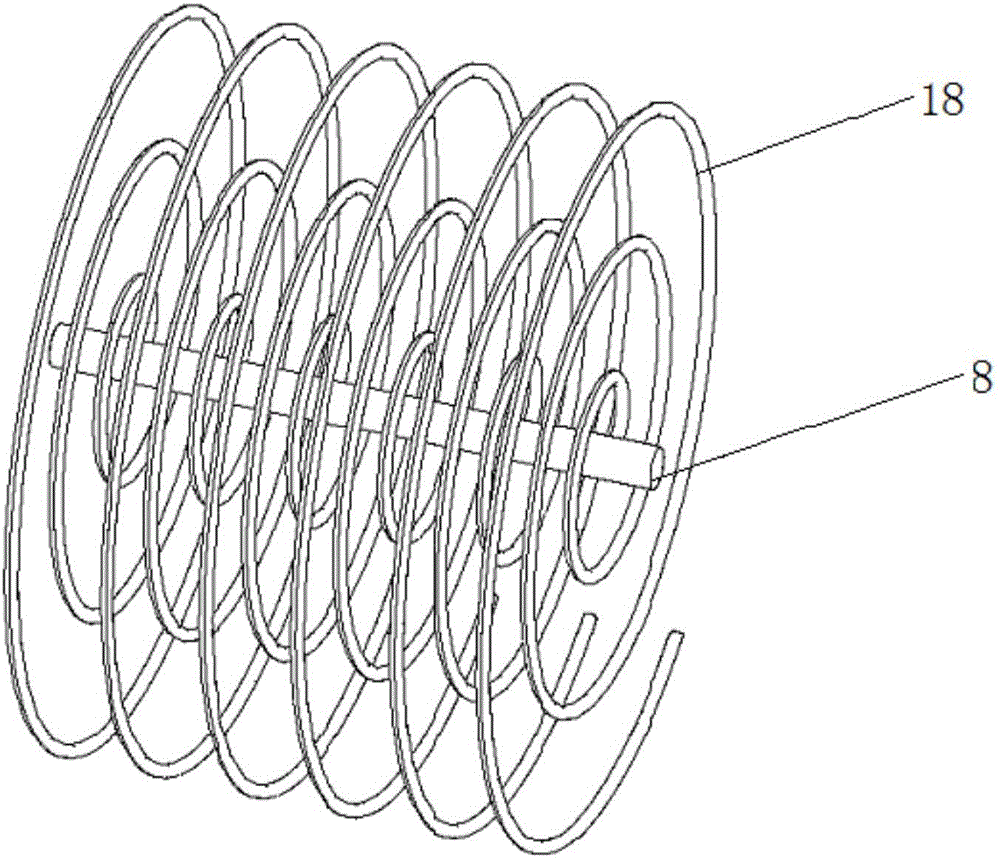

[0027] refer to Figure 1-4 An energy-saving and environment-friendly gas heating and hot water boiler, comprising a proportional burner 1, a furnace 11 and a PLC controller 16 electrically connected to the proportional burner 1, the proportional burner 1 is connected to a gas main pipe 8, and the gas main pipe 8 runs through the furnace 11 horizontally The outer wall of the furnace extends to the inner cavity of the furnace 11. The inner cavity of the furnace 11 is divided into three parts: the upper water vapor recirculation chamber 10, the middle combustion chamber connected with the recirculation chamber 10, and the bottom smoke exhaust chamber 22. The gas main pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com