A Broadband Small-Volume Acoustic Structure Based on Acoustic Metamaterials

An acoustic metamaterial, small volume technology, applied in the charging system, muffler device, intake muffler, etc., to achieve the effect of reducing muffling volume, ideal muffling effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

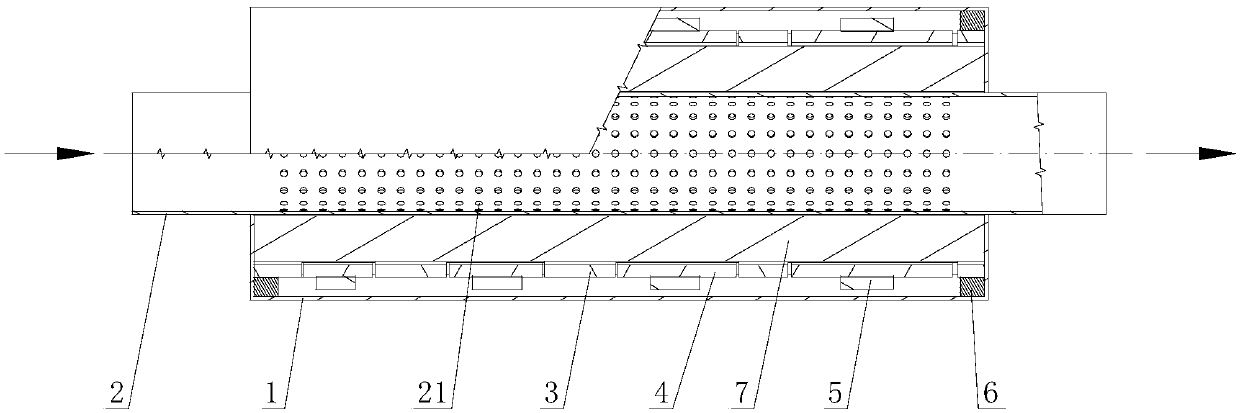

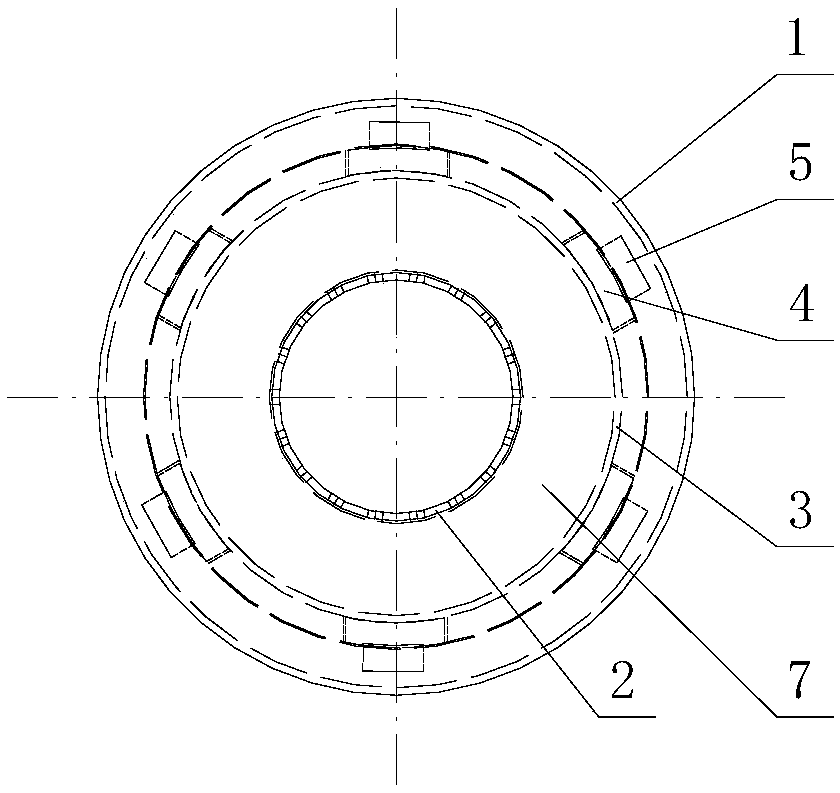

[0022] see figure 1 and figure 2 The shown broadband small-volume sound-absorbing structure based on acoustic metamaterials includes a shell 1 , a through-tube 2 , a thin-film sleeve 3 , a thin-film material 4 and a mass 5 .

[0023] The casing 1 has a hollow cavity, the through-pipe 2 is located in the hollow cavity of the casing 1, and the two ends of the through-pipe 2 respectively pass through the opposite ends of the casing 1 in the length direction and protrude into the casing 1 of the exterior. In this embodiment, the through-pipe 2 is connected to the housing 1 by welding.

[0024] The film sleeve 3 is also fixedly arranged in the hollow cavity of the housing 1 and sleeved on the outside of the through-tube 3 . In this embodiment, the film sleeve 3 is fixedly arranged in the housing 1 in such a way that a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com