Pavement splicing method and structure for old cement concrete pavement reconstruction and expansion

A technology of cement concrete and concrete pavement, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problem that two-way four-lane expressways are difficult to meet the traffic volume demand, road workers have no scientific and effective methods, and hinder the economy , social construction and development, etc., to delay the occurrence of pavement structural diseases, improve the relatively low and uneven intensity, and achieve good social and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

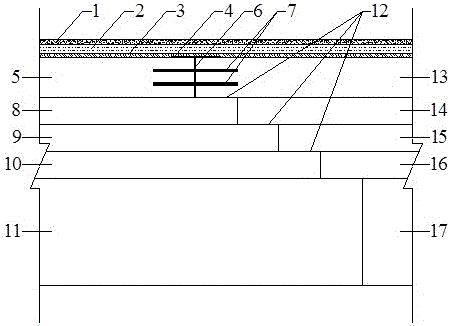

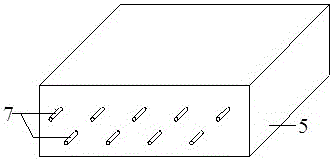

[0024] Such as figure 1 Shown, the pavement splicing structure of old cement concrete pavement reconstruction and extension of the present invention comprises asphalt concrete upper layer 1, asphalt concrete lower layer 2, asphalt concrete anti-crack leveling interlayer 3, anti-crack paste 4, old cement concrete panel 5, 6 panel joints, 7 steel bars, 8 base layers on the old road, 9 base layers under the old road, 10 cushion layers on the old road, 11 road beds on the old road, 12 steps, 13 cement concrete panels on the new road, 14 base layers on the new road, and under the new road Base layer 15, new road cushion 16, new road bed 17.

[0025]Among them, the joint 6 of the cement concrete panel is set on the hard shoulder of the old cement concrete panel 5, and the position is 1.9 m away from the soil shoulder; the old pavement structure is excavated along the joint 6 of the cement concrete panel to the side of the expansion structure, and the Steps 12 are set on the old roa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com