Special quenching inductor for rotary support rail

A technology of quenching inductor and slewing support, applied in the field of quenching inductor, can solve the problems of long existence time of quenching device, low efficiency and soft belt area, etc., achieve the effect of shortening induction quenching time, improving efficiency and ensuring quenching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

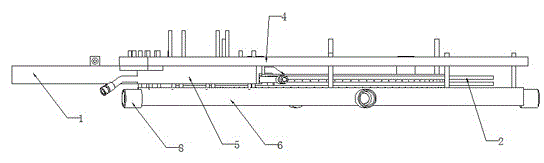

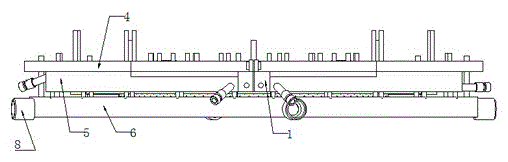

[0014] Such as figure 1 , figure 2 and image 3 As shown, a special quenching inductor for slewing support rails includes a pair of conductive connecting plates 1, an insulating pad is arranged between the pair of conductive connecting plates 1, and one end of the pair of conductive connecting plates 1 is connected to a ring-shaped effective heating ring. 2 connection, the effective heating ring 2 is made of copper tube, the other end of a pair of conductive connecting plates 1 is connected to the quenching equipment, and the effective heating ring 2 forms a closed current loop with the quenching equipment through a pair of conductive connecting plates 1, A pair of conductive connecting plates 1 and the effective heating ring 2 are provided with coolant channels. The effective heating ring 2 forms a circulating cooling liquid channel through the pair of conductive connecting plates 1 and the cooling liquid device. The effective heating ring 2 is provided with a clamping join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com