A method of improving the resistance of bacterial strains to inhibitors by using micro-aeration

A technology of inhibitors and bacterial strains, applied in the field of bioengineering, can solve problems such as unfavorable biotransformation, and achieve the effects of increasing xylitol yield, increasing yield, and reducing residual xylose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The micro-aeration of the present embodiment improves the method for the resistance of bacterial strains to cellulose hydrolyzate inhibitors, comprising the following steps:

[0033] 1) Take the Kluyveromyces marxianus 1727 (K.marxianus 1727) strain for seed cultivation and expanded cultivation; the cultivation process is specifically:

[0034] Seed culture: Prepare the seed liquid medium by sterilizing 10g / L of yeast powder, 20g / L of peptone, and 20g / L of glucose at 121°C for 15 minutes, and inoculate the K. marxianus 1727 strain to the culture medium, cultivated for 18h until the strain concentration reached OD 620 to 2~2.4;

[0035] Expansion cultivation: take the bacteria obtained in the seed cultivation, inoculate 6% of the inoculum into the shake flask containing the expansion medium, the expansion temperature is 30°C, the rotation speed is 150rpm, and the cultivation time is 14h until the strain concentration reaches OD 620 to 2~2.4;

[0036] The culture mediu...

Embodiment 2

[0041] In this embodiment, micro-aeration improves the resistance of bacterial strains to cellulose hydrolyzate inhibitors. The K. marxianus 1727 (K.marxianus 1727) bacterial strain is used for seed cultivation and expansion cultivation in the same manner as in Example 1. , and use the same fermentation broth and fermentation conditions for fermentation, the only difference is that the ventilation of 0.2vvm is maintained during the fermentation process;

Embodiment 3

[0043] In this embodiment, micro-aeration improves the resistance of bacterial strains to cellulose hydrolyzate inhibitors. The K. marxianus 1727 (K.marxianus 1727) bacterial strain is used for seed cultivation and expansion cultivation in the same manner as in Example 1. , and use the same fermentation broth and fermentation conditions for fermentation, the only difference is that the ventilation of 1vvm is maintained during the fermentation process;

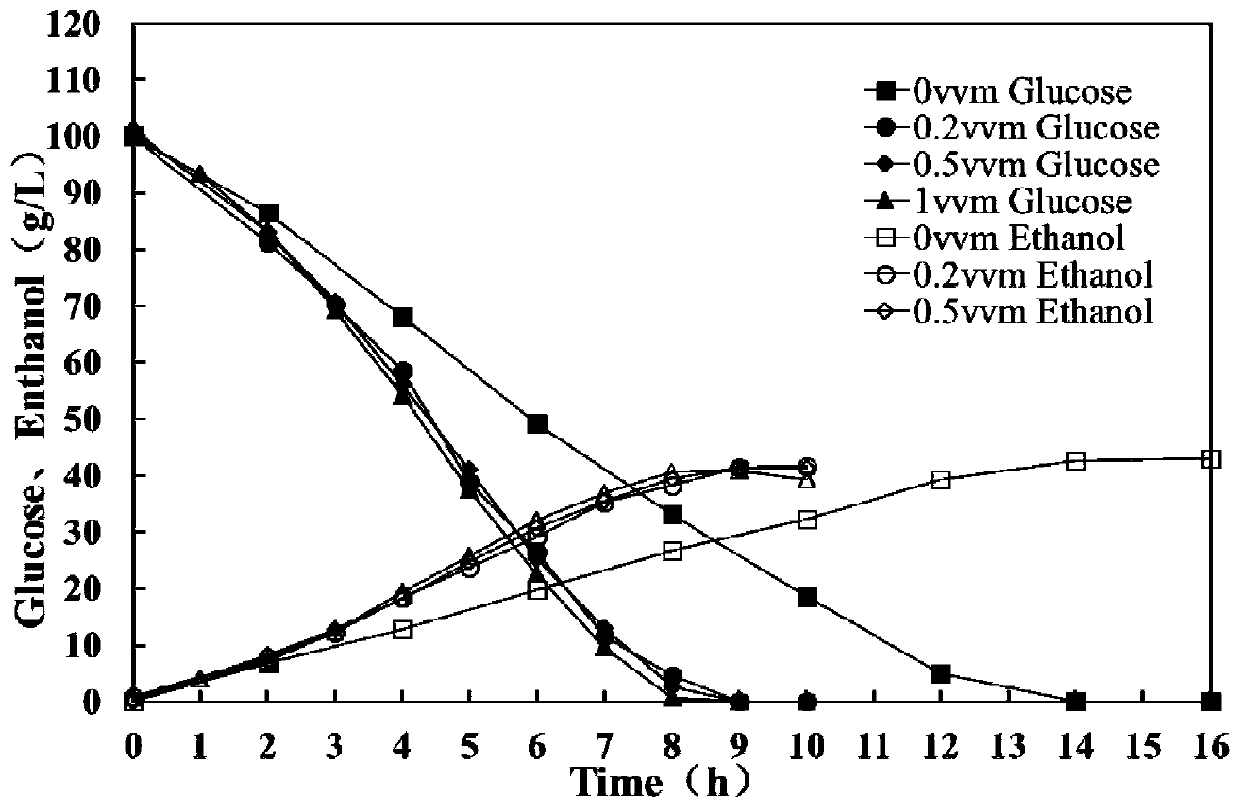

[0044] Result: by figure 1 It can be seen that in the presence of compound inhibitors, when 100g / L glucose is used as the carbon source, the fermentation performance of aeration and no aeration is significantly different; under the condition of slight aeration, the glucose consumption rate and ethanol production rate are significantly accelerated; Fermentation was just over, but under the conditions of 0.2, 0.5, and 1vvm, the fermentation ended after 8h, 9h, and 9h respectively, and the time was shortened by 43%, 36%, and 36% r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com