Preparation method of degradable vehicle lubricating oil

A technology for automotive lubricating oil and synthetic oil, which is applied in lubricating compositions, petroleum industry, etc. to achieve the effects of enhanced stability, good lubricating performance and excellent oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

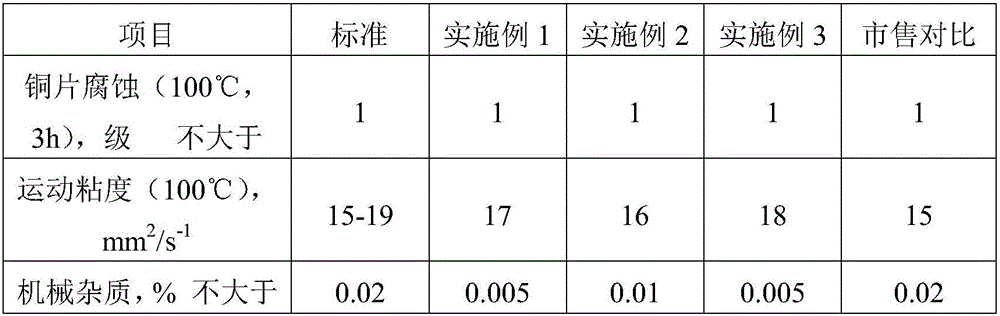

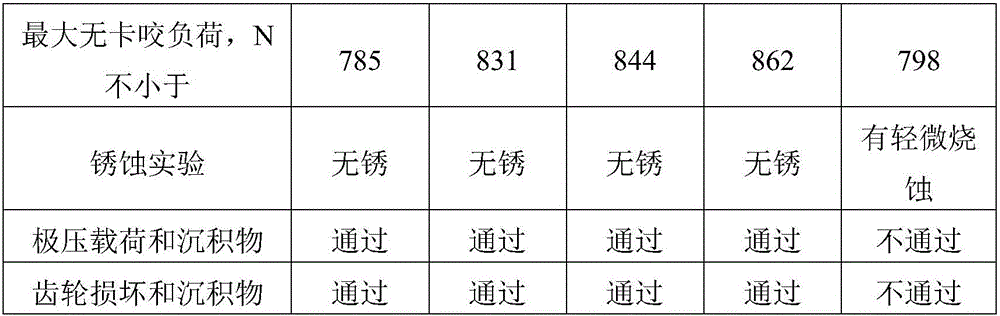

Examples

Embodiment 1

[0029] A degradable lubricating oil for vehicles, comprising the following components in parts by weight: 68 parts of plant-based synthetic oil, 10 parts of sodium-based bentonite, 2 parts of sasol wax, 15 parts of organic acid, 3 parts of chlorinated paraffin, clean 3 parts of dispersant, 12 parts of calcium hydroxide, 3 parts of anti-emulsifier, 3 parts of extreme pressure agent, 3 parts of antioxidant, 2 parts of anti-corrosion and anti-rust agent, 2 parts of flake graphite and 20 parts of water.

[0030] The plant-based synthetic oil comprises the following components in parts by weight: 10 parts of castor oil, 10 parts of cottonseed oil, 30 parts of water, 5 parts of triethanolamine, 3 parts of boric acid and 10 parts of oleic acid triethanolamine.

[0031] The preparation method of the plant-based synthetic oil described in this embodiment is step (A), comprising:

[0032] Step A-1) Mix castor oil, cottonseed oil and water, stir at a rotation speed of 45rps, and heat at ...

Embodiment 2

[0045] A degradable lubricating oil for vehicles, comprising the following components in parts by weight: 100 parts of plant-based synthetic oil, 15 parts of sodium-based bentonite, 4 parts of sasol wax, 20 parts of organic acid, 6 parts of chlorinated paraffin, clean 6 parts of dispersant, 15 parts of calcium hydroxide, 6 parts of anti-emulsifier, 6 parts of extreme pressure agent, 6 parts of antioxidant, 4 parts of anti-corrosion and anti-rust agent, 4 parts of flake graphite and 30 parts of water.

[0046] The plant-based synthetic oil comprises the following components in parts by weight: 15 parts of castor oil, 15 parts of cottonseed oil, 40 parts of water, 10 parts of triethanolamine, 8 parts of boric acid, and 12 parts of triethanolamine oleate.

[0047] The preparation method of the plant-based synthetic oil described in this embodiment is step (A), comprising:

[0048] Step A-1) Mix castor oil, cottonseed oil and water, stir at a rotation speed of 55rps, and heat at a...

Embodiment 3

[0061] A degradable lubricating oil for vehicles, comprising the following components in parts by weight: 85 parts of plant-based synthetic oil, 12 parts of sodium-based bentonite, 3 parts of sasol wax, 18 parts of organic acid, 5 parts of chlorinated paraffin, clean 5 parts of dispersant, 13 parts of calcium hydroxide, 5 parts of anti-emulsifier, 5 parts of extreme pressure agent, 5 parts of antioxidant, 3 parts of anti-corrosion and anti-rust agent, 3 parts of flake graphite and 25 parts of water.

[0062] The plant-based synthetic oil comprises the following components in parts by weight: 12 parts of castor oil, 13 parts of cottonseed oil, 35 parts of water, 8 parts of triethanolamine, 6 parts of boric acid and 11 parts of triethanolamine oleate.

[0063] The preparation method of the plant-based synthetic oil described in this embodiment is step (A), comprising:

[0064] Step A-1) Mix castor oil, cottonseed oil and water, stir at a rotation speed of 50rps, and heat at a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com