Standard substance for calibrating PM10 cutter, and preparation and certification method thereof

A standard material, cutter technology, applied in the direction of instruments, scientific instruments, particle and sedimentation analysis, etc., can solve the problem of inability to detect and calibrate the cutting characteristics of PM10 cutters, unable to calibrate and detect the cutting characteristics of PM10 cutters, and no cutting characteristics of PM10 cutters Detection and other problems, to achieve the effect of no change in particle size, accurate and reliable value, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

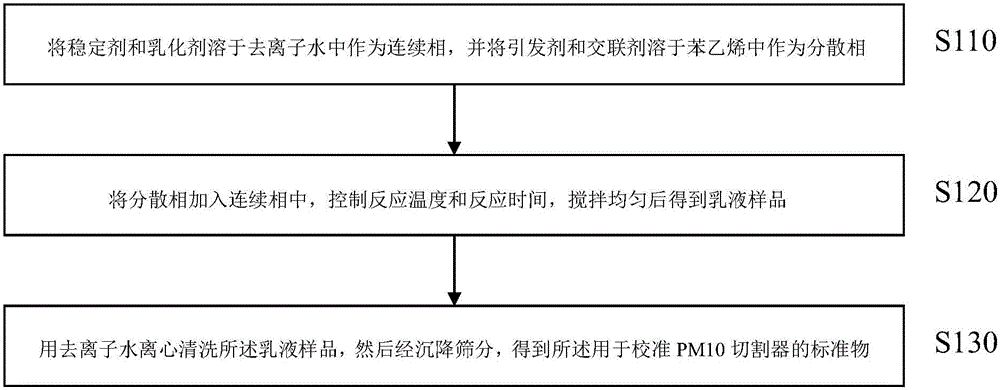

[0042] According to another embodiment of the present invention, the present invention provides a kind of preparation method that is used for calibrating the standard substance of PM10 cutter, comprises the following steps: preparation step: stabilizer and emulsifier are dissolved in deionized water as continuous phase, and Dissolving the initiator and cross-linking agent in styrene as the dispersed phase; reaction step: adding the dispersed phase to the continuous phase, controlling the reaction temperature and reaction time, and stirring evenly to obtain an emulsion sample; and separation step: centrifuging with deionized water The emulsion sample was cleaned, and then sieved by sedimentation to obtain the standard substance for calibrating the PM10 cutter.

[0043] According to another embodiment of the present invention, the above-mentioned preparation method also includes the following steps of determining the value: the first step, using an optical microscope and image an...

Embodiment 1

[0046] Embodiment 1, the preparation of standard substance of the present invention

[0047] The standard substance of the present invention is made up of 7 kinds of spherical particles, and is made through the following steps:

[0048] Preparation steps: Dissolve 4.90 g of polyvinyl alcohol and 2.24 g of sodium dodecylsulfonate in 100 mL of deionized water as the continuous phase, and 0.93 g of benzoyl peroxide and 3.12 g of divinylbenzene in 16.5 mL of styrene as the continuous phase. dispersed phase;

[0049] Reaction steps: adding the dispersed phase into the continuous phase, adjusting the stirring speed to 230r / min, and reacting at 85°C for 10h to obtain an emulsion sample; and

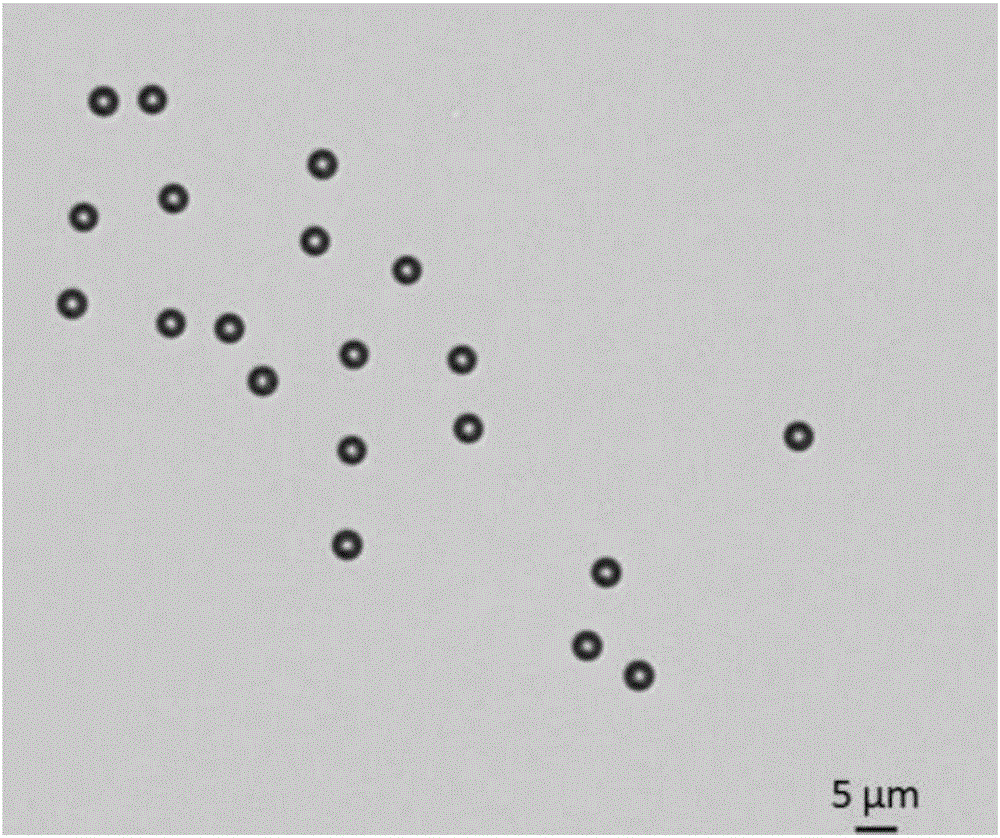

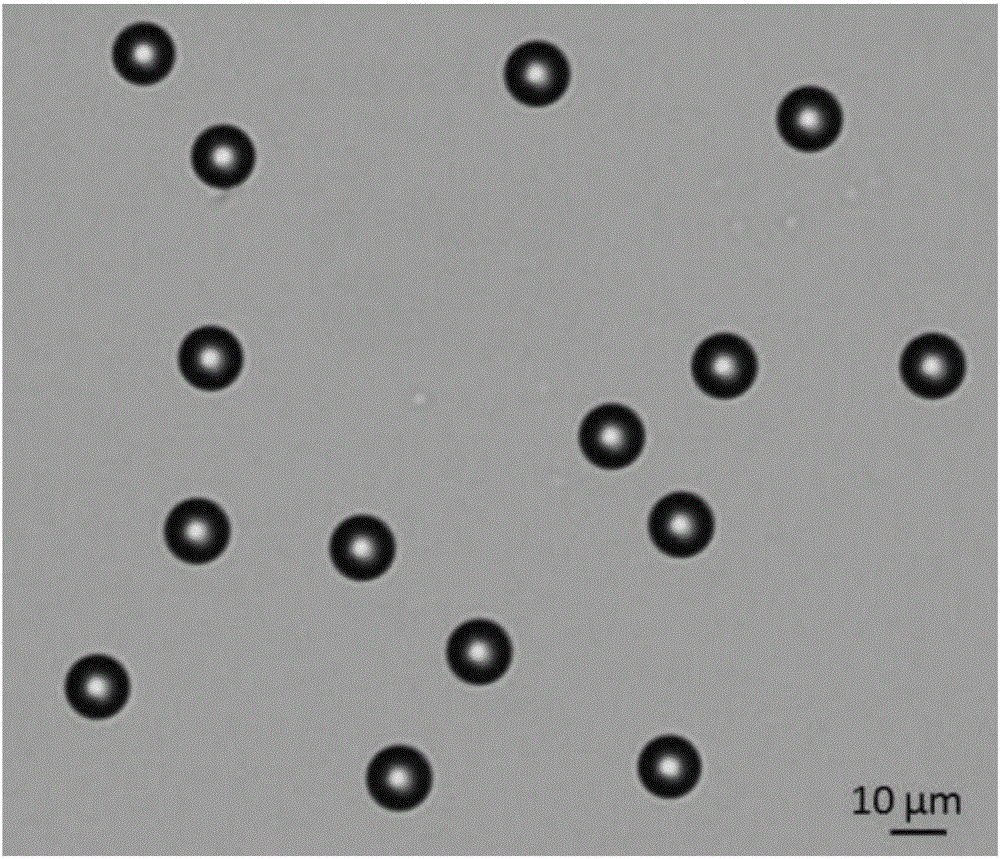

[0050] Separation step: Wash the emulsion sample several times with deionized water to remove unreacted reactants, then place the emulsion sample in deionized water, after settling for 8 hours, the upper layer of the emulsion sample is spherical particles of 5.0 μm, repeat this operation unti...

Embodiment 2

[0051] Embodiment 2, the preparation of standard substance of the present invention

[0052] The standard substance of the present invention is made up of 7 kinds of spherical particles, and is made through the following steps:

[0053] Preparation steps: Dissolve 3.60 g of polyvinyl alcohol and 2.24 g of sodium dodecylsulfonate in 100 mL of deionized water as the continuous phase, and 0.93 g of benzoyl peroxide and 1.44 g of divinylbenzene in 22 mL of styrene as the dispersion Mutually;

[0054] Reaction steps: add the dispersed phase to the continuous phase, adjust the stirring speed to 230r / min, and react at 80°C for 10h to obtain an emulsion sample; and

[0055] Separation step: Wash the emulsion sample several times with deionized water to remove unreacted reactants, then place the emulsion sample in deionized water, after settling for 8 hours, the upper layer of the emulsion sample is spherical particles of 5.0 μm, repeat this operation until The 5.0 μm spherical par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com