Preparation method of strengthened recycled aggregate and strengthened recycled aggregate concrete

A technology of recycled aggregate and concrete, which is applied in the field of the preparation of reinforced recycled aggregate and the field of reinforced recycled aggregate concrete, can solve the problems of restricting the development and application of load-bearing components and structures, high equipment requirements, limited improvement effect, etc., and achieves chloride ion diffusion. The effect of reducing the coefficient and shrinkage value, expanding the scope of application, and reducing resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of reinforced recycled aggregate: soak the recycled aggregate in a water glass solution with a mass concentration of 3%-20% and a modulus of 3.0-3.4, the solution is submerged in the recycled aggregate, and the soaking time is 10min-5h , take out the soaked recycled aggregates to dry naturally, dry and store them, and then get strengthened recycled aggregates. Table 1 shows the water absorption rate and crushing index of the recycled aggregate obtained by using different mass concentrations of water glass solutions for different soaking times.

[0021]

Embodiment 2

[0023] A preparation method of reinforced recycled aggregate: soak the recycled aggregate in a solution of potassium methyl silicate with a mass concentration of 1% to 15%, the solution is submerged in the recycled aggregate, and the soaking time is 5 to 10 minutes, and the soaked The recycled aggregates are taken out and dried naturally, and stored dryly to obtain strengthened recycled aggregates. Table 2 shows the water absorption rate and crushing index of the recycled aggregate obtained by using different mass concentrations of potassium methyl silicate solutions for different soaking times.

[0024]

Embodiment 3

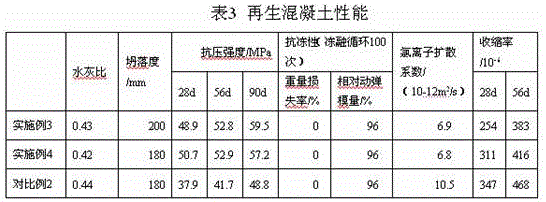

[0029] Use recycled aggregate (soaked in 5% water glass solution for 1h to strengthen treatment) to prepare recycled concrete, per m 3 Concrete includes the following raw materials by weight: 1016kg recycled aggregate, 223kg cement, 62kg fly ash, 68kg mineral powder, 800kg fine aggregate and 2.82kg water reducer. The slump of recycled concrete is controlled at (180±20) mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com