A method for purifying and treating waste water produced by gallic acid with nano-silica gel

A technology for gallic acid and waste water production, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, natural water treatment, etc., to achieve the effect of simplified process, simplified resource recovery and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

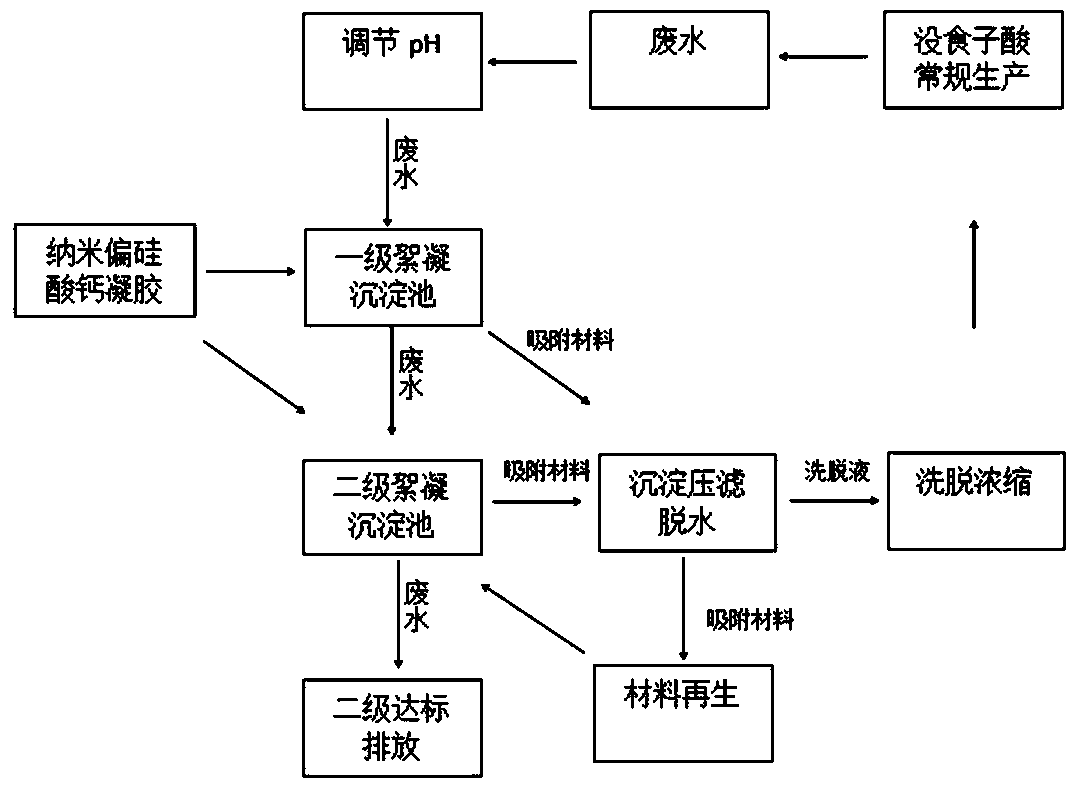

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Treatment of processing wastewater from Galla Chinensis with the maximum dosage of nano silicone gel

[0023] pH value 1.41, gallic acid content 1.46%, salt content 10.21%, COD Cr The 28086 mg / L gall processing wastewater is adjusted to pH 10 with lime milk with a mass percentage concentration of 15% in the storage tank, and then introduced into the primary flocculation sedimentation tank. Add calcium metasilicate nano gel to the primary flocculation tank at a dosage of 50g / L, stir and absorb for 4 hours, and then settle for 2 hours. The wastewater treated by the primary tank flows into the secondary flocculation tank, and the amount of calcium metasilicate nanogel is 50g / L, stirred and adsorbed for 3 hours, and then precipitated for 2 hours. The removal rate of gallic acid is 93.57% for the wastewater purified and treated by this secondary flocculation tank, and the wastewater COD = 88.75mg / L.

[0024] Adjust the pH of the nano-silica gel sediment in the primary...

Embodiment 2

[0026] Example 2: Treatment of processing wastewater from Galla Chinensis with minimum dosage of nano-silicon gel

[0027] pH value 1.41, gallic acid content 1.46%, salt content 10.21%, COD Cr The 28086 mg / L gall processing wastewater is adjusted to pH 10 with lime milk with a mass percentage concentration of 15% in the storage tank, and then introduced into the primary flocculation sedimentation tank. Add calcium metasilicate nano gel to the primary flocculation tank at a dosage of 40g / L, stir and absorb for 4 hours, and then settle for 2 hours. The wastewater treated by the primary tank flows into the secondary flocculation tank, and the amount of calcium metasilicate nanogel is 40g / L, stirred and adsorbed for 3 hours, and then precipitated for 2 hours. The removal rate of gallic acid is 90.24% for the wastewater purified and treated by this secondary flocculation tank, and the wastewater COD = 94.46mg / L.

[0028] Adjust the pH of the nano-silica gel sediment in the primary or s...

Embodiment 3

[0030] Example 3: The optimal dosage of nano silicone gel is used to treat the processing wastewater of Chinese gall

[0031] pH value 1.41, gallic acid content 1.46%, salt content 10.21%, COD Cr The 28086 mg / L gall processing wastewater is adjusted to pH 10 with lime milk with a mass percentage concentration of 15% in the storage tank, and then introduced into the primary flocculation sedimentation tank. Add calcium metasilicate nano gel to the primary flocculation tank at a dosage of 50g / L, stir and absorb for 4 hours, and then settle for 2 hours. The wastewater treated by the primary tank flows into the secondary flocculation tank, and the amount of calcium metasilicate nanogel is 40g / L, stirred and adsorbed for 3 hours, and then precipitated for 2 hours. The removal rate of gallic acid is 92.26% for the wastewater purified and treated by this secondary flocculation tank, and the wastewater COD = 90.05mg / L.

[0032] Adjust the pH of the nano-silica gel sediment in the primary o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com