Milling tool and method for machining tooth sockets through tool

A milling tool and tooth groove technology, which is applied in the field of tooth groove processing, can solve the problems of long processing time and low efficiency, and achieve the effect of short processing time, high consistency and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

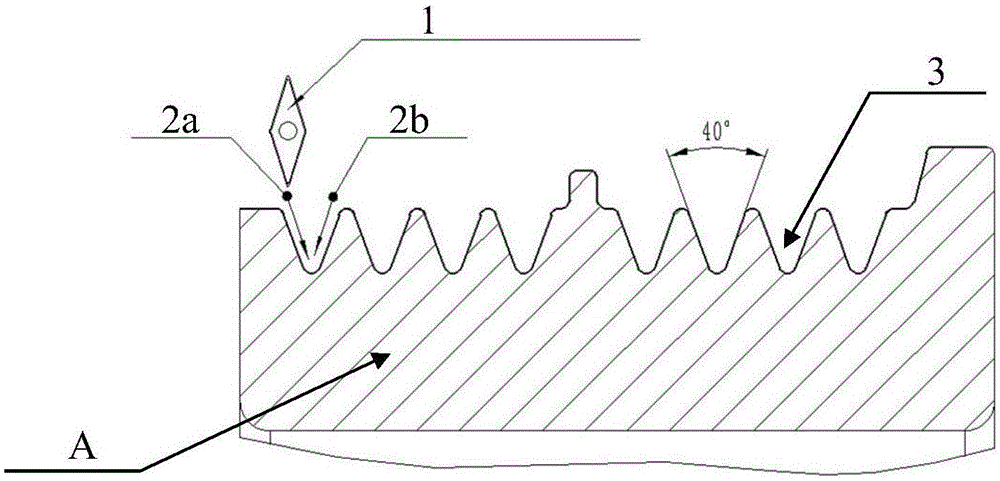

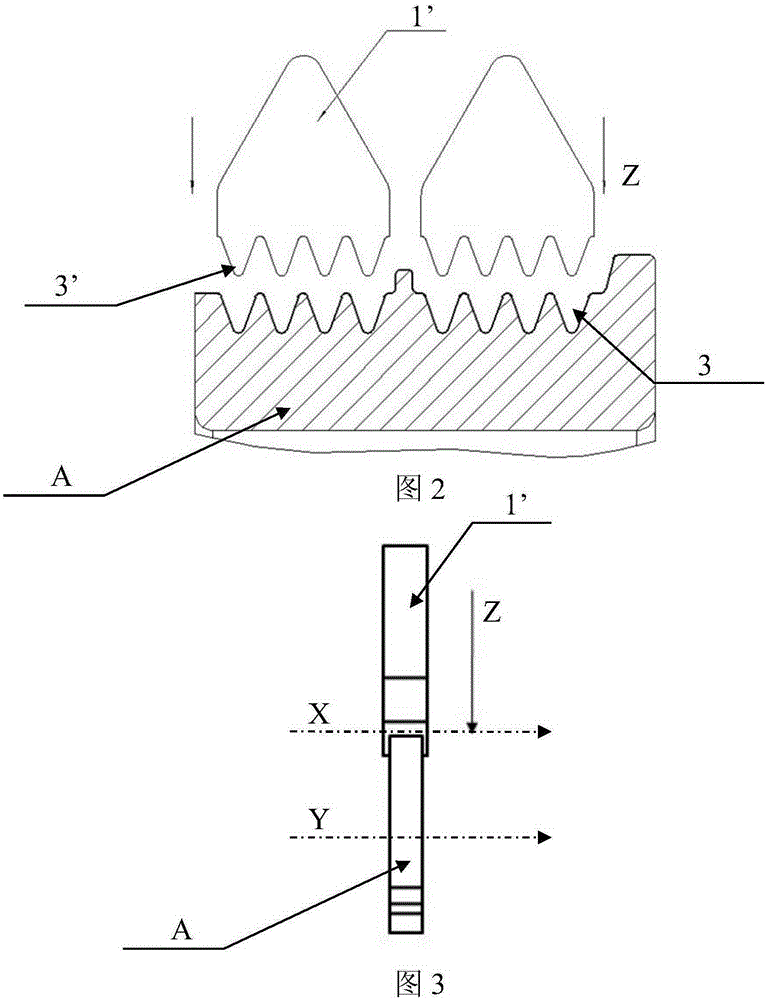

[0023] As shown in Figure 2, there are 8 tooth grooves 3 on the workpiece A that need to be processed, and the consistency of the cross-rod spacing of the tooth grooves is required to be no greater than 0.03mm, and the profile degree is not greater than 0.4mm. A plate-shaped milling tool for processing the tooth grooves 3 on the workpiece A, the end portion of which includes at least one blade 1', the top surface of which is provided with at least one toothed edge group, the toothed edge group forms There are four addendums 3', the outer contour of the addendum 3' matches the outer contour of the tooth groove 3 of the workpiece to be processed.

[0024] The method of applying the above-mentioned milling tool to process the tooth groove, the steps are as follows:

[0025] S1, installing the milling tool on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com