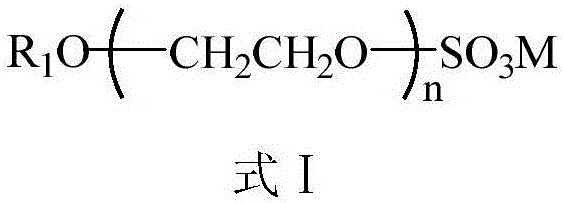

Composite thickening agent-type alcohol ether sulfate surfactant

A technology of alcohol ether sulfate and surfactant, which is used in surface active detergent compositions, non-ionic surface active compounds, detergent compounding agents, etc., can solve the problem that the viscosity of high active products increases and the AES products are easy to delaminate. and other problems, to achieve the effect of overcoming poor solubility, good practical application value and shortening dissolution time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

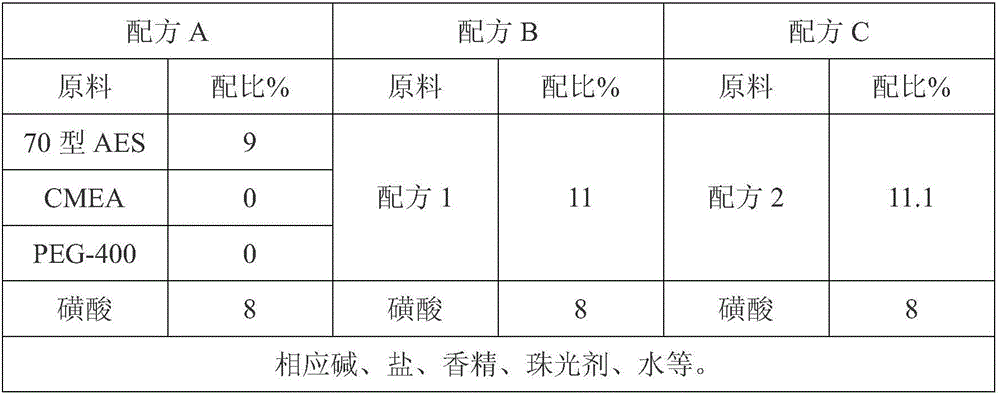

[0035] Application of compound thickener type alcohol ether sulfate surfactant in compound formula.

[0036] Prepare composite thickener type alcohol ether sodium sulfate surfactant according to the following raw materials and mass proportion respectively:

[0037] Formula 1: 70 type fatty alcohol polyoxyethylene ether sodium sulfate (AES): cocoic acid monoethanolamide (CMEA): PEG-400 = 9:2:0;

[0038] Recipe 2: 70 type fatty alcohol polyoxyethylene ether sodium sulfate (AES): cocoic acid monoethanolamide (CMEA): PEG-400=9:2:0.1

[0039] It was further applied in the following washing product formulations A, B and C:

[0040]

[0041] From this, the viscosity changes of detergent product formulations A, B and C at different temperatures were measured:

[0042] temperature(℃) Formula A Formula B Formula C 46.5 18 242 305 37 43 958 1018 30 84 3318 3216 16.5 447 16020 13340 9 3144 42600 24950

[0043] It can be seen that t...

Embodiment 2

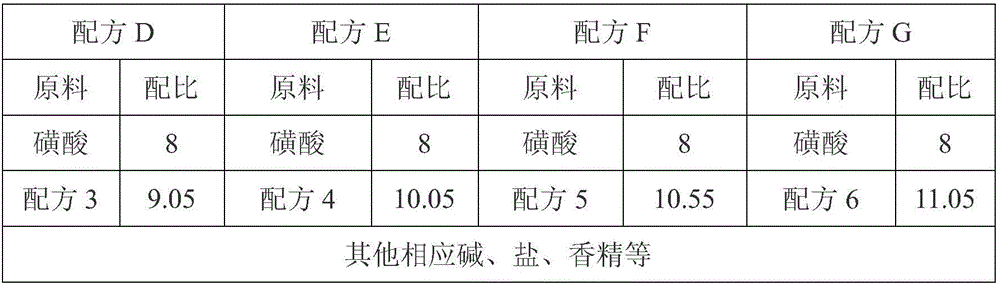

[0045] Prepare composite thickener type alcohol ether sodium sulfate surfactant according to the following raw materials and mass proportion:

[0046] formula Type 70 Sodium fatty alcohol polyoxyethylene ether sulfate (AES): Cocoic acid monoethanolamide (CMEA): PEG-200 3 9:0:0.05 4 9:1:0.05 5 9:1.5:0.05 6 9:2:0.05

[0047] Preheat cocoic acid monoethanolamide to 67°C-71°C to melt it, then add it and PEG-200 according to the required mass fraction and add 70 type fatty alcohol polyoxyethylene ether that has been preheated to about 65°C Sodium sulfate, stirring and vacuum degassing, until uniform without bubbles, cooled to room temperature, to obtain a compound thickener type alcohol ether sodium sulfate surfactant.

[0048] It is further applied to compound washing product formulations D, E, F and G:

[0049]

[0050] From this, the viscosity changes of detergent product formulations D, E, F and G at 30°C were measured:

[0051]

Embodiment 3

[0053] Application of compound thickener type alcohol ether sulfate surfactant in compound formula.

[0054] Prepare composite thickener type alcohol ether sodium sulfate surfactant according to the following raw materials and mass proportion respectively:

[0055]

[0056]

[0057] Add the required mass fraction of coconut acid diethanolamide and PEG-200 into the 70-type fatty alcohol polyoxyethylene ether sodium sulfate, stir and vacuum degas until it is uniform and free of bubbles, and the surface of the compound thickener type alcohol ether sodium sulfate is obtained. active agent.

[0058] It was further applied in the following washing product formulations H, I, J, K and L:

[0059]

[0060] From this, the viscosity changes of washing product formulations H, I, J, K and L at different temperatures were measured:

[0061] temperature(℃) Formula H Recipe I Recipe J Formula K Formulation L 50 23 121 110 115 106 40 53 521 460 46...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com