The end effector of the fruit and vegetable picking robot

An end-effector and picking robot technology, applied in the field of machinery, can solve the problems of inability to achieve fruit picking, unfavorable storage and grasping accuracy, and inability to cope with fruit picking, etc., to achieve good promotion value, improve picking speed, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of the present invention will be described in further detail below with reference to the accompanying drawings.

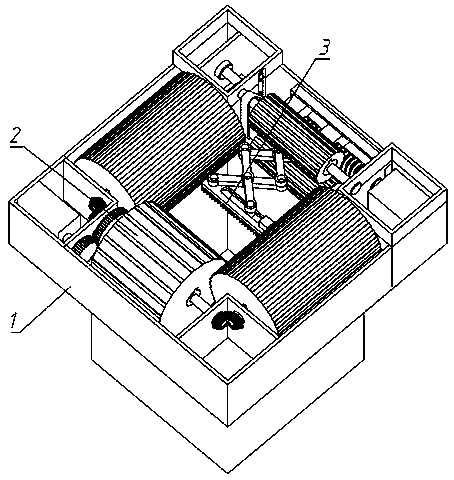

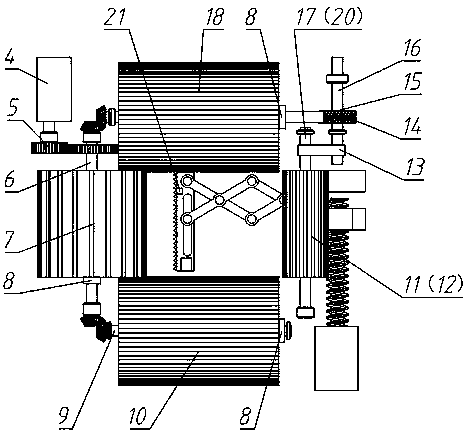

[0016] Such as figure 1 , As shown in Figure 2(a), the end effector consists of four parts: grasping system, cutting system, sensor control system, and shell.

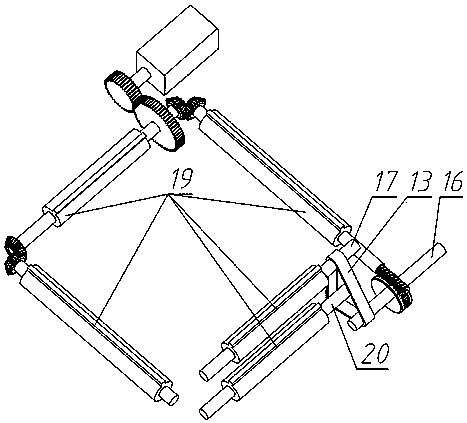

[0017] Grabbing system 2 is mainly composed of grabbing system motor 4, spur gear 5, straight bevel gear shaft I6, rubber roller I7, straight bevel gear shaft II9, rubber roller II10, rubber roller III11, rubber roller IV12, tooth shape Chain 13, worm 14, turbine 15, turbine shaft 16, small roller shaft I17, rubber roller V18, roller connecting sleeve 19, small roller shaft II20; the spur gear 5 and the straight toothed cylindrical gear installed on the 4th shaft of the grabbing system motor The toothed bevel gear shaft I6 meshes, and the straight-toothed bevel gear shaft I6 meshes with the straight-toothed bevel gear shaft II9. At the same time, the straight-toothed beve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com