Anti-seismic movable floor assembly

A raised floor and assembly technology, which is applied to local raised floors, elastic floors, insulating layers, etc., can solve the problems of thin bracket and stringer system, conflict of bracket items, and no consideration of seismic performance, so as to achieve firm and easy connection. Maintenance and replacement, good load-bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

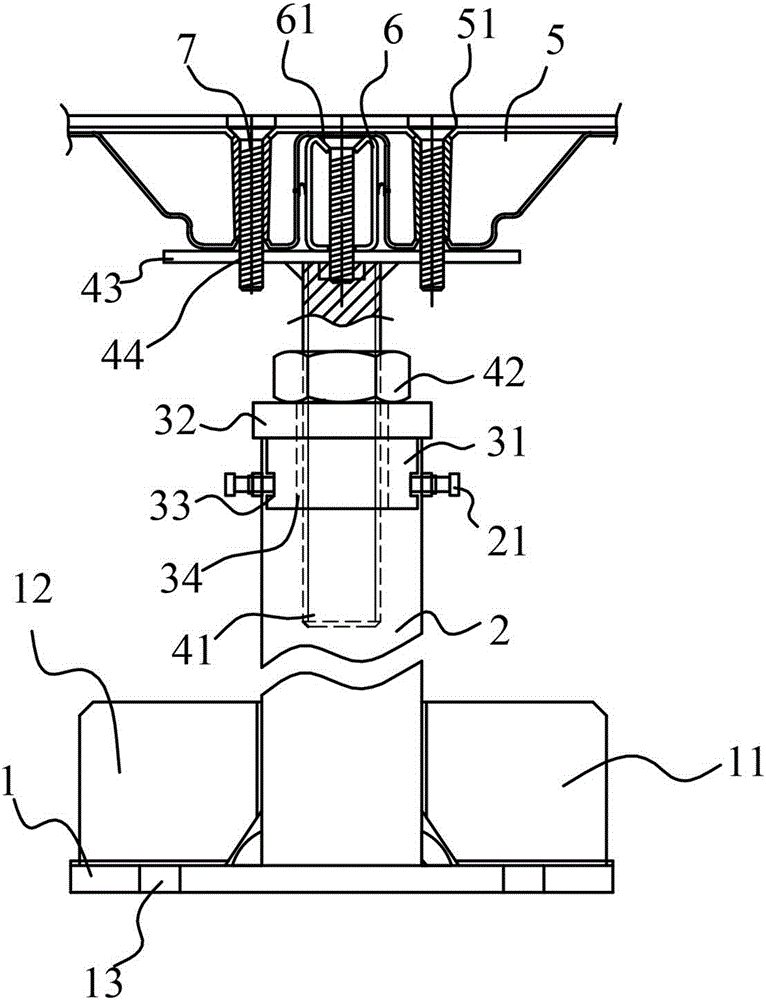

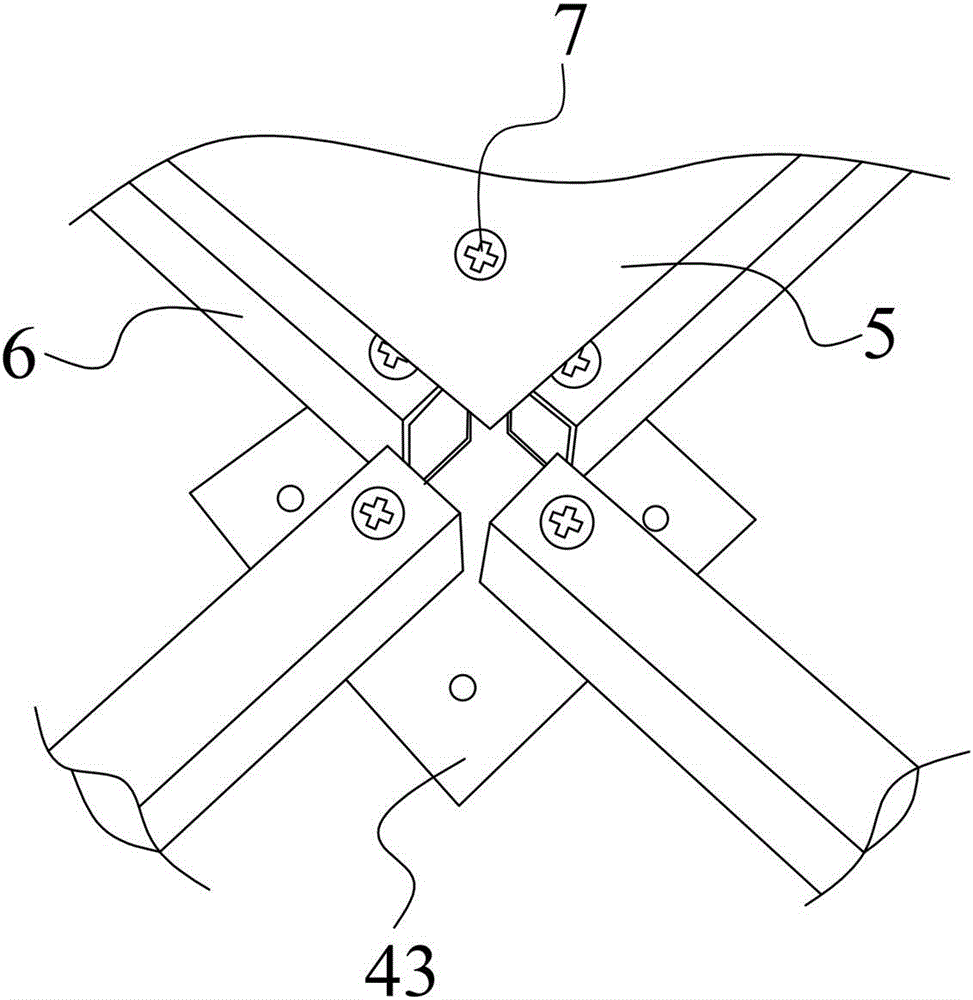

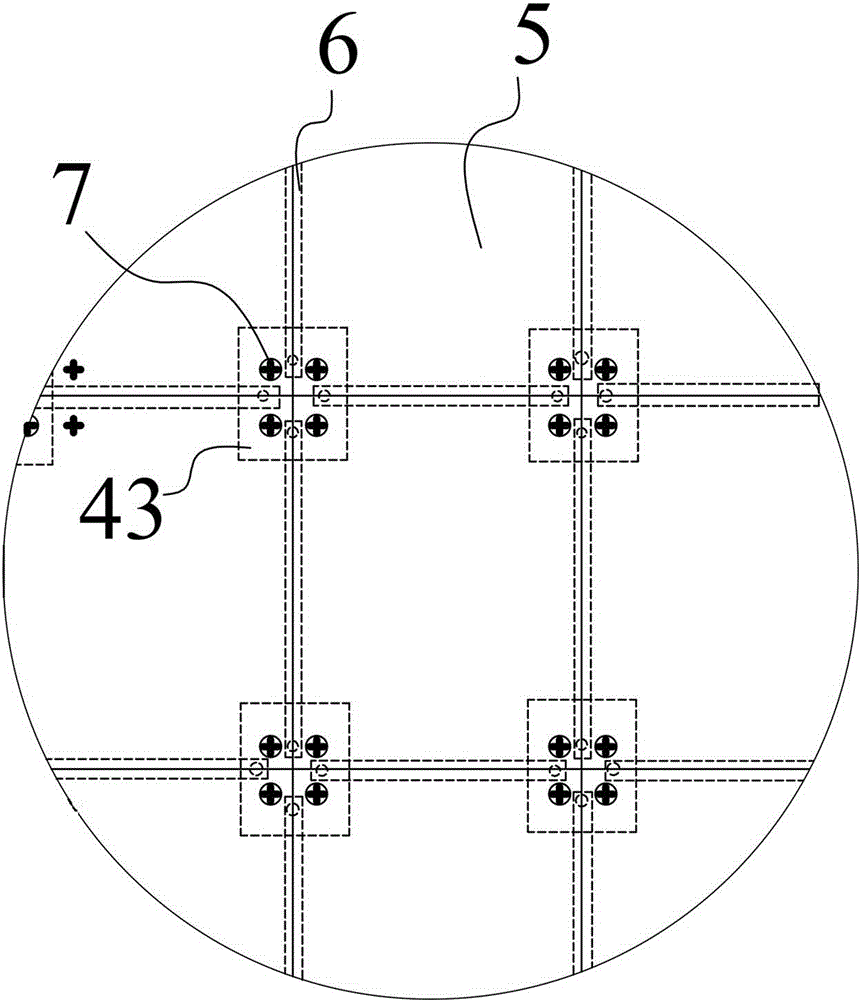

[0020] Such as Figure 1 to 5 As shown, an earthquake-resistant raised floor assembly includes a frame and a number of floors 5 laid on the frame. The frame includes a number of brackets and stringers 6, and two adjacent supports are connected by stringers 6 Each of the four corners of the floor 5 is provided with a first through hole 51, a bracket is placed under each first through hole 51, and the floor 5 is connected to the bracket by a detachable thread through the first through hole 51, And one edge of the two floors 5 is placed on the same stringer 6.

[0021] The bracket includes a base 1, a sleeve 2, a tray, and a support block. One end of the sleeve 2 is fixedly connected to the base 1, and a support block is installed at the other end of the sleeve 2. A locking screw 21 is provided on the pipe wall at one end.

[0022] The support block has a front end 32 with a diameter larger than the outer diameter of the sleeve 2 and a rear end 31 with a diameter smaller than the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com