Low-smoke halogen-free irradiated polyethylene with high strength and high fire resistance and preparation method thereof

A high flame-retardant, high-strength technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of poor mechanical properties and low heat-resistant temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Put ethylene copolymer, ethylene vinyl acetate copolymer, flame retardant, interfacial compatibilizer, and antioxidant into the internal mixer, and the processing temperature range is 120-145°C. The mass ratio of ethylene copolymer, ethylene vinyl acetate copolymer, flame retardant, interfacial compatibilizer and antioxidant is 100:50:250:20:10:2.5. Among them, the VA content in EVA is 18%, the flame retardant is aluminum hydroxide, the interface compatibilizer is maleic anhydride grafted ethylene-vinyl acetate copolymer, the lubricant is stearic acid, and the antioxidant is stearic acid. Alcohol Esters (Antioxidant 1076).

[0031] EVA is made from ethylene-vinyl acetate copolymer (also known as ethylene-vinyl acetate copolymer) by copolymerization of ethylene (E) and vinyl acetate (VA). The English name is: Ethylene Vinyl Acetate, referred to as EVA, E / VAC.

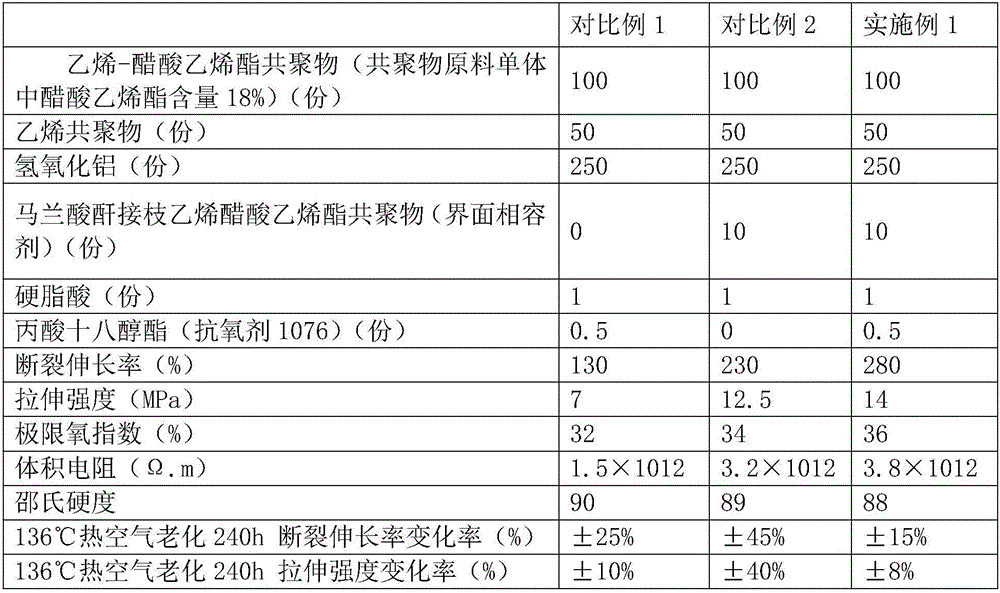

[0032] Table 1 Comparative example 1, comparative example 2, embodiment 1 make each performance data table o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com