Down-like fiberfill material and manufacturing method therefor

A manufacturing method, feather-like technology, applied in the direction of textiles and papermaking, yarn, fiber processing, etc., to achieve a full sense of weight, large volume, and superior thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Below, refer to Figure 1 to Figure 24 The new and brand-new feather-like cotton raw material and its manufacturing method that are artificially manufactured to imitate the shape of natural feathers that do not exist in the prior art will be described in detail.

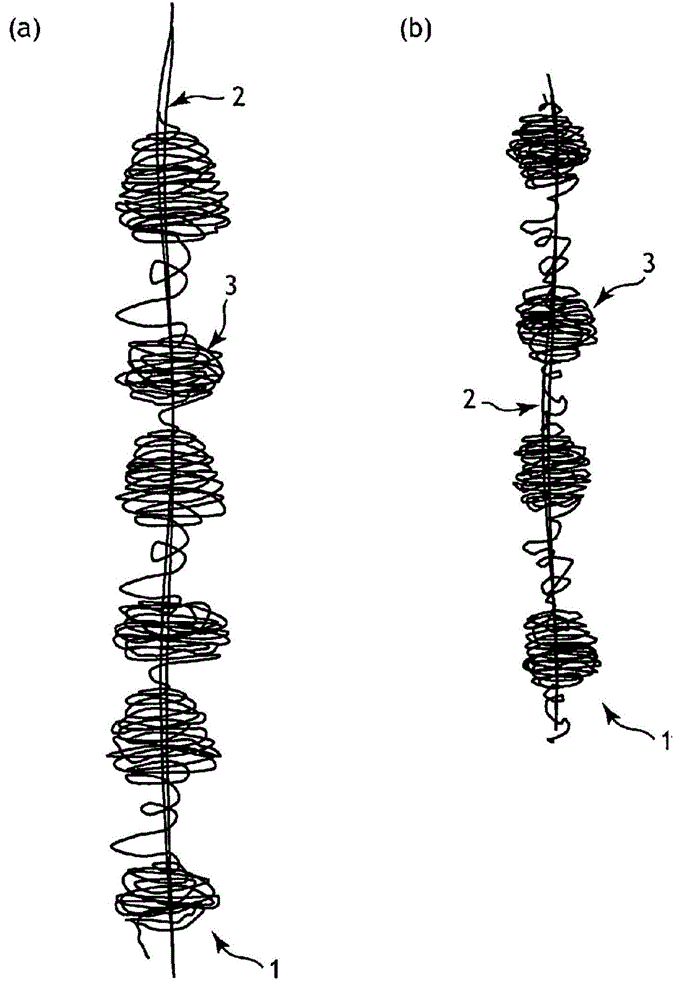

[0045] figure 1 (a) is a schematic diagram showing a feathery cotton raw material 1 in the form of a line diagram. The feathery cotton raw material 1 is formed in a relatively large fluffy ball-shaped block artificially imitating a feather in the embodiment of the present invention, and is The state in which long fibers like cotton are formed and finished. figure 1 (b) is a schematic diagram showing a feathery cotton raw material 1 according to an embodiment of the present invention in the form of a line diagram. The feathery cotton raw material 1 is formed by artificially producing fluff ball-shaped blocks in a shape imitating feathers. figure 1 The size of (a) is small, and it is the state in which long fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com