An open liquid nitrogen self-circulation rapid cooling system

A fast cooling, open technology, applied in cooling/ventilation/heating renovation, electrical components, electrical equipment structural parts, etc. Cracks, low requirements for equipment and operating environment, and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Embodiment: An open liquid nitrogen self-circulation rapid cooling system.

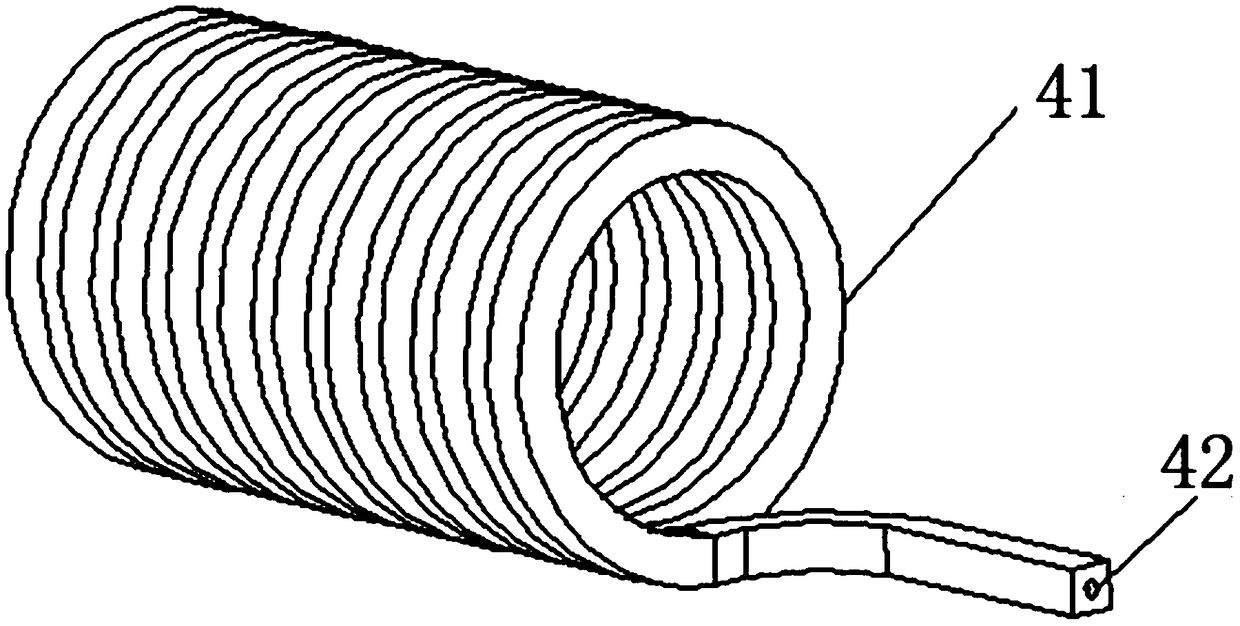

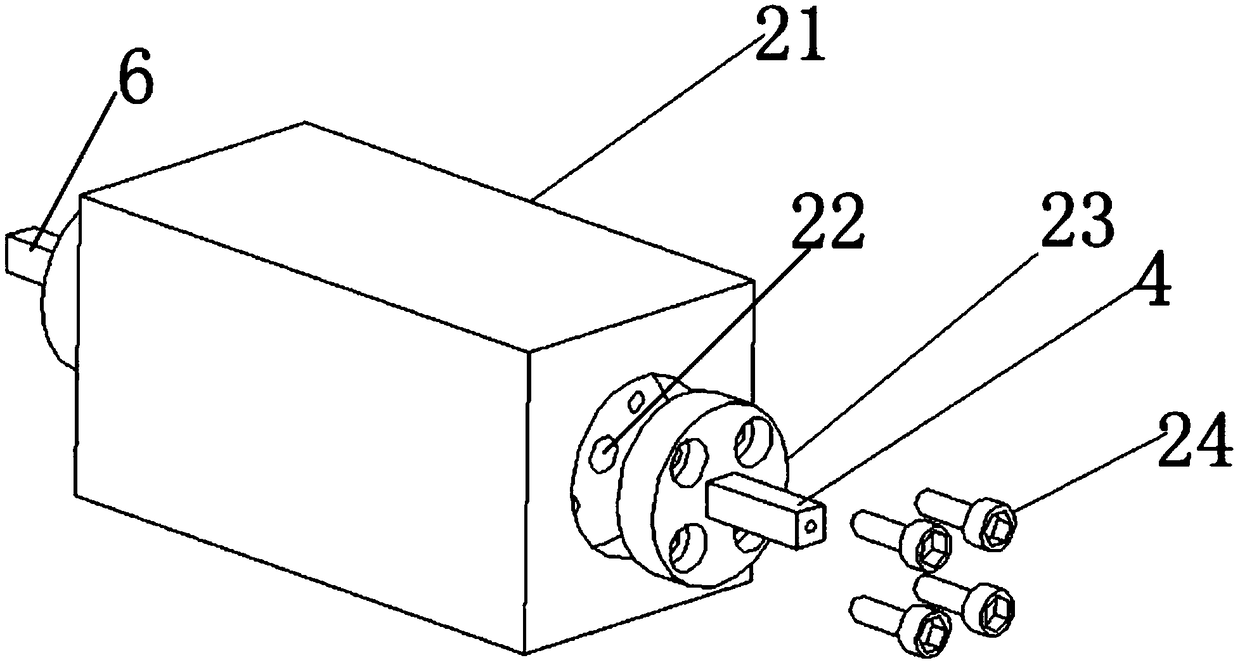

[0021] refer to figure 1 , figure 2 with image 3 As shown, an open liquid nitrogen self-circulation rapid cooling system includes: a liquid nitrogen tank 1, the liquid nitrogen tank 1 is connected to the atmosphere, and the liquid nitrogen tank 1 is filled with liquid nitrogen 5; installed in the liquid nitrogen tank 1 or A liquid nitrogen pump 6 outside the liquid nitrogen tank 1; a low-temperature insulating material connecting block 2 installed in the liquid nitrogen tank and completely impregnated with liquid nitrogen, the center of the low-temperature insulating material connecting block 2 is provided with a through hole 22, and the through hole One end of 22 is connected to the output port of the liquid nitrogen pump 6; the electromagnetic coil 4 installed at one end of the low-temperature insulating material connection block 2, the electromagnetic coil 4 is formed by coiling an elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com